When you walk the floor of the SEMA Show in Las Vegas, it’s tough to decide which direction to look. There are amazing cars, engines and parts in every direction! Despite the cool factor, which can disorient you off course, I made a point to visit the guys over at the Mast Motorsports booth. They typically showcase a couple awesome engines, and this year they had a number of goodies on display – both in their own booth and in other booths around the show.

I spoke with Perry Kiritsy, who’s in charge of Mast Motorsports’ cylinder head department, about some of the engines Mast had at the show. After deliberating over which one he’d like to shine a spotlight on, we walked away from the Mast booth and over a few rows to see a 466 cid LS7 engine Perry had recently built for a customer’s Chevelle SS.

Perry started working at Mast Motorsports in October 2009 as an engine builder. He cut his teeth in that role for seven years before moving to the parts department for two years. Recently, he made another transition to begin running the cylinder head department.

“I’ve been a Jack of all trades at Mast,” Kiritsy says. “I’ve been running the cylinder head department for three months now. It’s been fun.”

Mast Motorsports, which is located in Nacogdoches, TX, started as a custom crate engine builder. It later acquired a cylinder head company out of necessity for better cylinder heads, which turned Mast into a custom engine outfit as well as a manufacturer of cylinder heads and intakes for hotrods, muscle cars, airboats and more.

“We started off with the Gen IV LS,” Kiritsy says. “We started out doing cam swaps and basic, custom engine builds, and then it turned into a full-service race engine shop. We only do the LS engine. We’ve tried to dip our toe into the Coyote market, but those have been hard to sell. We also just merged with Endyn out of Fort Worth, TX. It’s owned by Larry Widmer, and he and Darren Morgan, formerly of Reher-Morrison, are running a cylinder head division up there. That’s been new as well.”

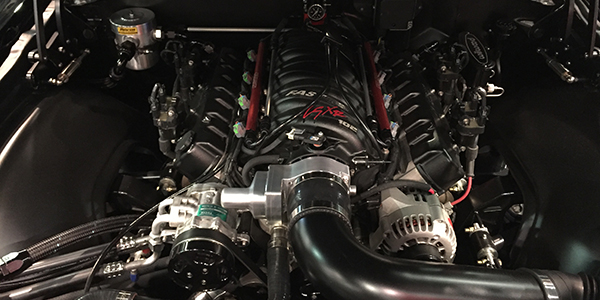

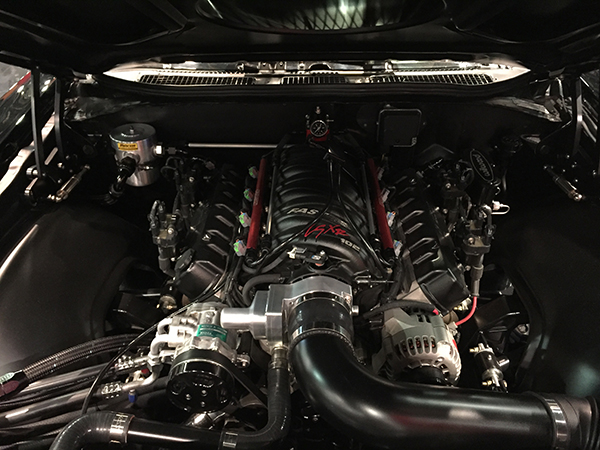

Those developments have helped Mast Motorsports become a leader in the LS engine world, and the 466 cid LS7 engine inside a customer’s Chevelle SS at SEMA, was evidence of that.

“The customer came to us looking for an engine that was a little bit different than the run of the mill 408, 416 or LS7-type deal,” Kiritsy says. “We ended up getting him into a 466 cid RHS-based block. He wanted pump gas, but he wanted big power and big torque for the street, so we built him the engine with a 4.165˝ bore and a 4.300˝ stroke with a hydraulic roller.

“We got the block straight from RHS and took the main caps off and made sure everything was clean. We always cut a couple thousandths off of the main caps and we put a fresh line hone on them no matter what the block is, whether it’s new or old. From there, we used our Rottler F65 and bored out the block because the block came in at 4.125˝. We took a few thousandths off the deck and cut the deck to 9.720˝. That’s usually where I set my tall deck stuff. After that, we hone it on our SV10 diamond hone and off to the assembly room it goes. The RHS block didn’t require any stroker clearancing at all with the 4.300˝ arm, which made it go together really nice.”

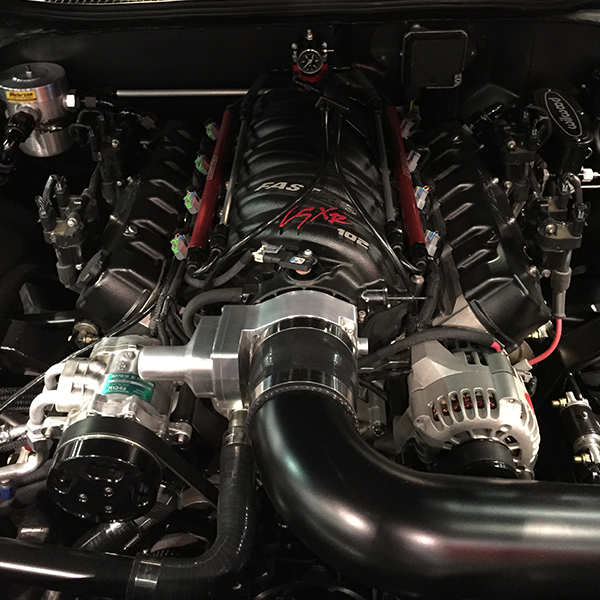

The 466 LS7 got a Callies Magnum crank, which Mast Motorsports exclusively uses, as well as a set of Callies 6.460˝ Ultra H-beam rods. The pistons for the engine came from Diamond.

“We had a piston made for the 466 because we started building a lot of them as an engine combination for drift racing, and we really, really liked it,” he says. “We did a chamber mold and worked with Diamond to get a piston that was really good. It’s got a 10cc dish in it, so it’s still 11.5:1 compression and its pump gas friendly. This engine has a really good bottom end.”

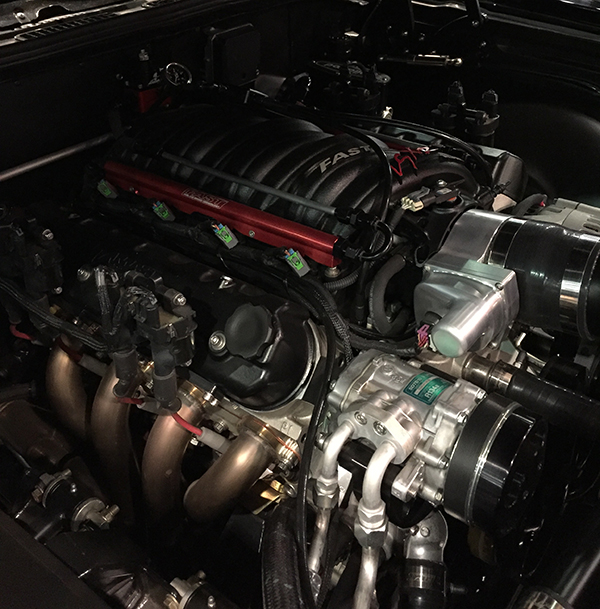

Some of the other components on the LS7 include COMP cams, which have a duration in the mid 250s-260s at 50 and 650 lift, Johnson lifters, T&D rockers, Pac 1207 valve springs, Manton pushrods, and a Dailey Engineering dry sump oiling system.

“We don’t turn a lot of rpm – we turn about 7,200 – but with the 4.300˝ arm, it’s really staunch down low,” he says. “It makes 550-ft.-lbs. from cam to cam and peaks right around 630 ft.-lbs. The cylinder heads on this engine are our 305 LS7 heads. It’s a large port LS7 head. We use a 2.250˝ valve with a 1.600˝ exhaust. It’s one of our castings and we make all the tooling in-house. We have it poured up in Michigan and then we do all the machine work. This is our most popular cylinder head.”

Normally aspirated, Perry says he’s seen engines make 930 hp on this head and countless numbers of customers making over 2,000-2,500 hp when adding boost.

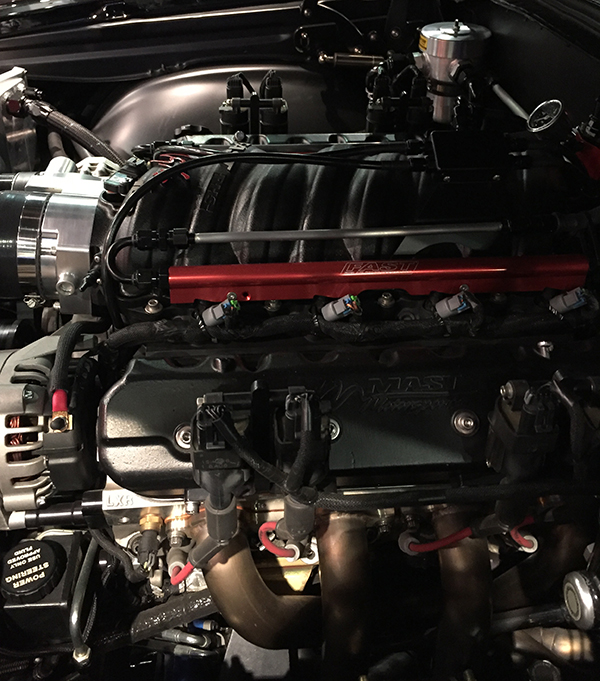

“It’s a really good cylinder head,” he says. “The customer didn’t want a big cowl or have to cut a hole in the hood, because it’s a really nice car, so we stuck with the FAST 102 intake manifold on it. His intentions are to do some autocross stuff.”

The 466 cid LS7 engine made 640-ft.-lbs. of torque and 750 horsepower normally aspirated. With the FAST 102 intake, big engines like this one actually run out of manifold, but that doesn’t stop this from being a great engine.

“It’s a really good combination for the street,” Kiritsy says. “The customer called recently needing some tuner assistance, because it has our drive-by-wire Mast Motorsports ECM and wiring harness, and there’s not a lot of people who can tune it.”

Once Mast Motorsports gets the tune in proper order, this will be one bad Chevelle SS with a heck of a powerplant inside!

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].