When Bruce McKillop met Chris Bland working at a GM dealership together, the two struck up a friendship that would later extend beyond the car lot and into the vast world of motorsports.

Bruce had come from a dealership background, having worked for GM car dealerships in the parts department to running the service department to overseeing dealerships to being a co-owner of a GM accessory center. Chris, on the other hand, came up on the technician side of things and became a GM world-class technician, of which there’s only a small handful out of 66,000 technicians in the country.

“I’ve been in the GM world since 1981,” McKillop says. “Chris worked for me at a dealership and he was building engines out of his garage and I offered to partner up with him to help him out. At the time, I never had intentions of working there, but then the car business got slow in 2006, and they eliminated my position at the dealership, so I ended up coming over to CBM Motorsports.”

Bruce and Chris officially rolled out CBM (Custom Built Motors) Motorsports in Colton, CA in August 2006, and today the two co-owners run the shop, which specializes in LS engine work.

“That’s our cup of tea,” McKillop says. “We have a super wide variety of customers from the hot rod user looking to upgrade their ‘69 Camaro to doing motors for the Fast and the Furious stunt cars. We did the Batmobile in the latest Batman movie. We do the camera cars for the movie business because they need faster motors to keep up with those stunt cars. We do the Drift series, King of the Hammers, Baja 1000, trophy trucks, class one cars, but our biggest market is the sand rails.

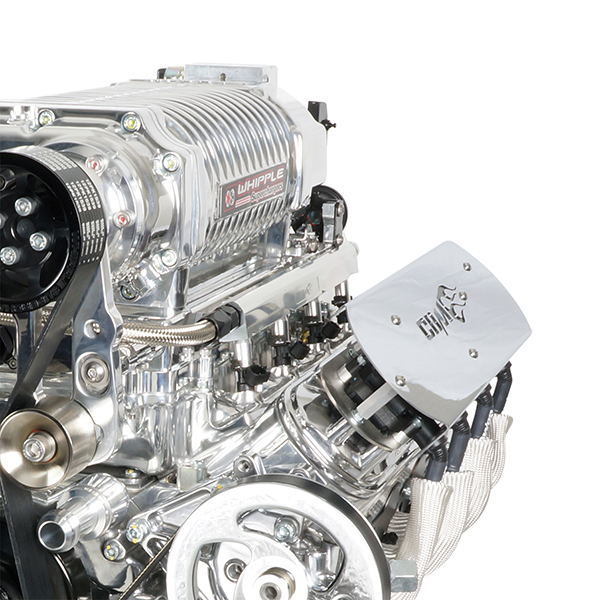

“We’re primarily engine builders, but we also have a full catalog online that you can order parts through. We manufacture a lot of our own bracketry, pulleys, valve covers – anything aluminum – we make here. We’ve designed our own cylinder heads. We buy bare castings and then we CNC port them and had custom Jesel rockers made for them.

“We also have a service center where we install engines. We make our own harnesses. We’re a MoTec, AEM and Holley dealer, so we can program or dyno tune as well.”

With all of those capabilities in one spot, CBM Motorsports’ facility is 45,000 sq.-ft. on four and a half acres. The shop has two buildings – a parts building and a service building – two Mustang chassis dynos and soon an engine dyno, as well as a 10,000 sq.-ft. show room to sells cars. A building this size also means it takes a team to handle the work load, and CBM employs 26 full-time folks.

“A build typically takes about four weeks,” McKillop says. “That’s where it’s handy to have 26 people. We have a cylinder head guy, we’ve got an assembly guy, we’ve got the accessory guy – everyone has a role. We’re also kind of family run – my two boys work here, and Chris’ wife is the office manager. We try to keep the family involved.”

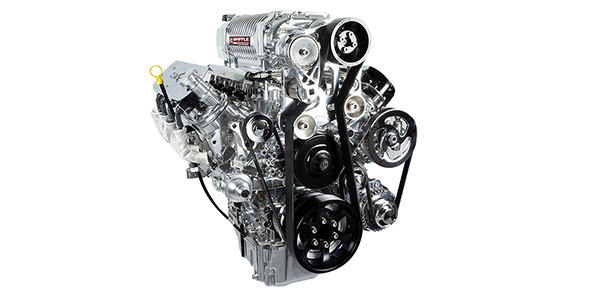

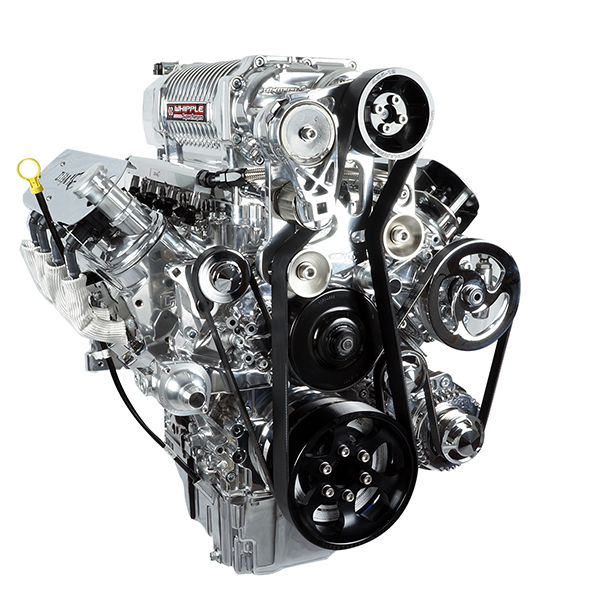

One of the more recent engines the CBM family got involved with was a 440 cid Whipple-blown LS engine for an off-road sand rail application.

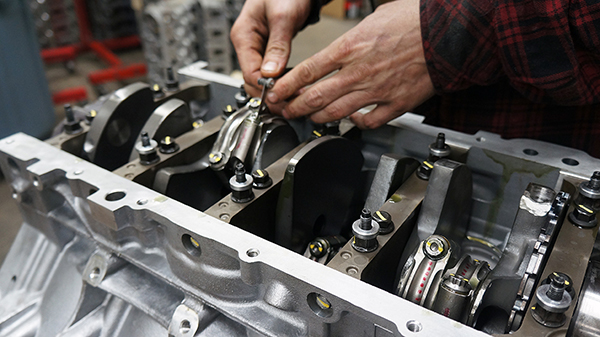

“This engine features a CBM Pro X block and CBM Pro X heads,” he says. “It’s got a Callies DragonSlayer crankshaft and Callies Ultra I-beam rods, JE forged pistons, a Total Seal stainless ring package, Manley 700 dual race springs, titanium retainers and severe-duty stainless valves. It’s also got a Melling oil pump in it and what we call our CBM 600-plus hydraulic roller camshaft with 650 lift and 248/252 duration on a 114 lobe center.”

The heads get CNC ported and CBM ensures the engine is honed, balanced and blue printed for peak performance.

“We measure all the specs and everything gets documented,” McKillop says. “We wade through the block to make sure the clearances are correct. We measure piston-to-wall clearance and we measure deck height, etc.”

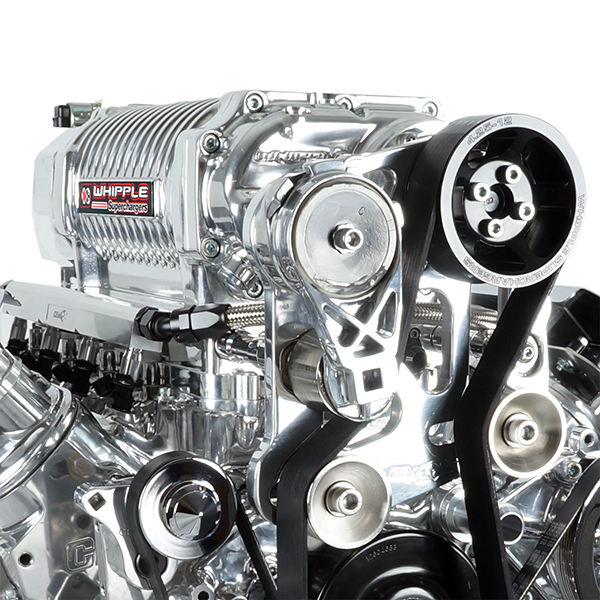

This particular 440 LS got a fully polished block, heads and blowers. It has a 4.5 Whipple supercharger and CBM’s own pulleys. It’s also got a billet 250 amp CBM alternator, a MoTec computer system, and full Motec PDM.

“This motor will make approximately 850 hp to the wheel on pump gas on 12 psi of boost and is capable of up to about 1,100 rear wheel hp and about 20 lbs. of boost on 110 octane race fuel,” McKillop says. “The compression is 9:1.”

All said and done, the LS build went together without any issues, and that’s thanks to the skilled team at CBM and its impressive parts inventory.

“We had no issues with this build,” he says. “We do so many that we have everything in stock to build it. We stock about $1M in inventory, so we try to keep enough to build 10-12 motors.”

The 440 cid twin Whipple LS is now giving hell to the off-road world in a Funco sand rail car.

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].