Engine of the Week is presented by

We’ve featured Kyle Whetsel and Brad Simoneau of RPM Performance & Machine in our Engine of the Week series once before. We’ve also featured the shop’s outboard marine engine work and expertise in the magazine recently too. However, when we came across this 482 cubic inch Ford FE engine build the Fort Walton Beach, FL-based shop recently did, we couldn’t help but tip our cap to the shop once more.

Kyle and Brad were college roommates at the University of Northwestern Ohio (UNOH) when they first met. Now, more than a decade later, the two friends run RPM Performance & Machine, a shop that Kyle was an employee of for just one year before he bought the business from its original owner who retired in 2015. Brad spent 11 years working for the Engine Factory in New Jersey following his days at UNOH.

As Kyle was looking to build the business and Brad was looking for better weather, the stars aligned for Kyle and Brad to reunite on the job front. Kyle has owned RPM for six years now, and Brad started at the shop in August 2018. The shop has five full-time employees, and according to Simoneau, RPM is the only engine machine shop in town.

“We do anything and everything that hits the door,” Simoneau says. “We do anything from just rebuilding a customer’s cylinder head to big horsepower boat motors. We’re starting to branch off into the turnkey market and doing a lot with LS engines. We also do a lot of FE motors. That’s a big market for us as well. We also see the 351 and 400M Clevelands and we do some outboard marine engines, Merc cruisers, and small block and big block Chevys.”

RPM is able to tackle all those different builds and do anything that walks in the door because the shop is a full machine shop capable of doing all work in-house.

“We’ve got an RMC CNC mill we do all of our block work and head work in,” he says. “We’ve got a Sunnen CV 616. We’ve got a Winona Van Norman seat and guide machine – it’s a full machine shop and we’re capable of doing anything that comes in. We also have a Dynojet chassis dyno and an engine dyno.”

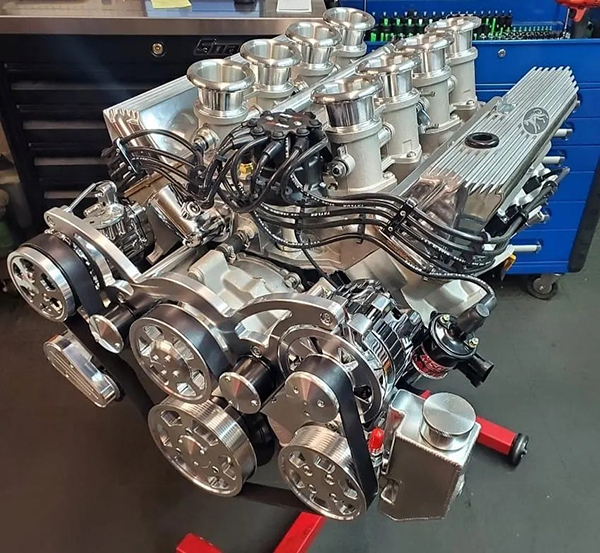

One of the shop’s more recent builds was one of those popular Ford FEs RPM is known for building. According to Brad, this is an engine that’s been a long time coming and anyone who stopped by the shop probably saw it. With the stacks it really raised eyebrows.

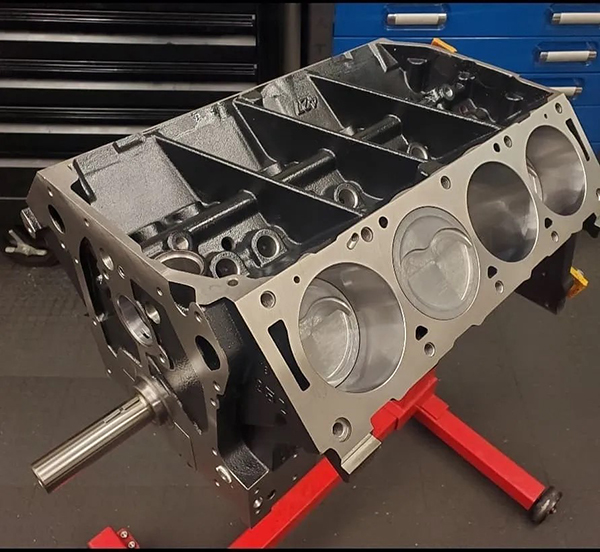

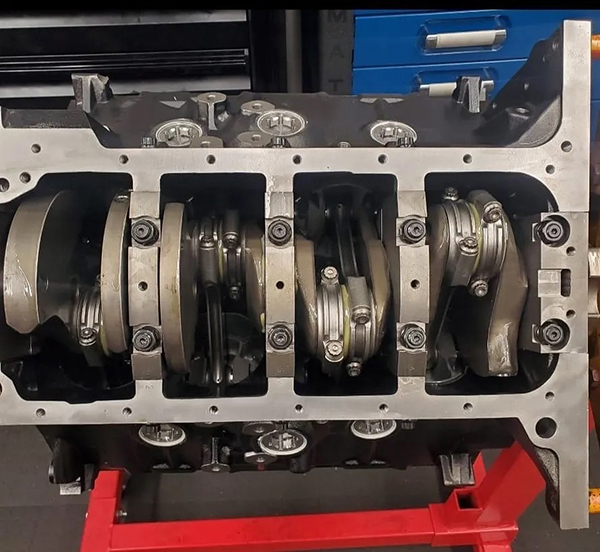

The engine started with a Bear 427 cid FE side oiler block, which got enlarged to 482 cubic inches because the customer of the build specifically reached out asking for a badass engine. That’s exactly what RPM delivered.

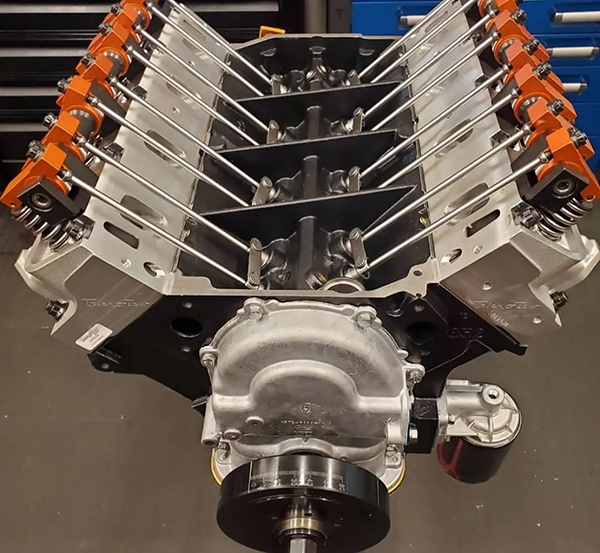

The 482 cid Ford FE features plenty of power thanks to the Borla Induction stack injection and Holley Terminator X EFI. Kyle and Brad called up Scat Crankshafts to get one of their forged 4.250˝ stroke rotating assemblies with Mahle pistons to fit into the new Bear block.

The shop worked closely with Ken out at Oregon Cams to get the right combo to work with the Trick Flow Specialties CNC-ported cylinder heads that got topped with Harland Sharp rockers.

The engine recently got put on the engine dyno for break-in and horsepower numbers and made 610 hp and 609 lb.-ft. of torque!

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].