Just a few years ago, if you saw a 30-foot boat with twin 250-hp outboard engines on the back of it, you’d stop dead in your tracks and think, ‘Wow, that’s really something.’ Today, twin 250s are the mid-range offshore boat. In recent years, the outboard engine has really experienced explosive growth and people have come to understand how good of a power plant it really is.

From single cylinder engines to four cylinders and all the way to V6 and V8 power plants, outboards can deliver 2.5 hp to 600+ hp, and the desire for more keeps climbing. Combined with the fact that you can stand up while you’re working on them and not have to worry about crawling down into a bilge, there’s definitely advantages to outboards. With today’s outboards capable of producing so much more power than they used to, you’re seeing boats get bigger and bigger and bigger that are outboard powered.

“There are boats out there now that are 65-feet long powered by outboard engines,” says David Meeler, Yamaha’s new product introduction manager. “Ten years ago, that would have been insane – nobody would have ever thought that was possible.”

With the evolution of the outboard motor continuing to experience an upward trajectory, the opportunities for engine builders to do outboard engine work is growing exponentially. Boats with twin configurations, triples, quads, quints, and so on, will need a trustworthy shop for regular maintenance and engine rebuilds.

Outboard Basics

First off, outboard engines are available in two different main configurations – one being a two-stroke engine and the other being a four-stroke engine. Over the past 10 years, the two-stroke outboard has all but faded away in today’s market.

“The only one to my knowledge right now making the two strokes would be the Evinrude E-Tec,” says Kyle Whetsel, owner of RPM Performance and Machine in Fort Walton Beach, FL. “Everyone used to make them, so there’s still a lot of them out there that we rebuild. The two strokes are a completely different animal from the four strokes. They run roller bearings inside. They have hardened crankshaft journals, so they can’t be reground. It’s just a different animal entirely. The four-stroke stuff would be very similar to what you find in cars. Pretty much everything on the market now is a dual overhead cam set up.”

In fact, according to Yamaha, the last two stroke it manufactured was in 2009. However, shops like RPM Performance and Machine will work on just about any outboard engine, with the exception of small outboards, 50 horsepower and less, which are cost prohibitive for the shop to work on.

“You can just buy replacements cheap enough so it’s not worth getting into,” Whetsel says. “Most of the outboards we see are for cruisers and fishing boats.”

The biggest share of the market are indeed the family boaters/cruisers. These are people who like to go out and hang out on the water or go to the beach or take the boat out to the restaurant.

“In the past, we were seeing a lot of the cuddy cabin-style boats that came with the IOs (inboard/outboards), which would typically be a Chevrolet engine,” Whetsel says. “They’ve slowly been transitioning to more and more outboards and we’re seeing less and less of those IOs. The outboards are definitely a lot less maintenance. I think that’s why people are going to them, and they’re making them a lot bigger nowadays too, with more horsepower than they had in the past.”

Another large portion of the outboard engine market are fishing vessels. Both commercial boats and recreational fishing boats are finding outboards to be the engine of choice.

“The most recent engine we just introduced, is what we call the XTO – a 5.6L outboard with 425 horsepower,” Meeler says. “When you have the offshore fishing vessels, that’s where our XTO lives. In those circles, it sells extremely well. Obviously, you don’t put a 952-lb. motor on a bass boat. In the bass boat realm, you have our VMAX SHO engines, which sell very well. The big seller is the 150, which is kind of the jack of all trades, all-around engine that shows up on all kinds of different boats. That’s a huge seller. There’s different engines and different horsepower for different purposes. We have a number of really popular sellers throughout our lineup.”

While Yamaha is certainly one of the big players in the outboard engine market, other OEMs such as Evinrude, Honda, Suzuki and Mercury are well-known outboard manufacturers as well.

“We actually don’t see a lot of Hondas, and they’re a really good engine,” Whetsel says. “The initial cost to buy one is quite a bit higher than the other manufacturers. We do the Mercury Verados, which are supercharged, inline six cylinders. We do Yamahas, which are probably the biggest one we see. They make inline four cylinders, V6s and V8s. We also see quite a few Suzukis.”

Outboard Rebuilds

While four strokes are the primary outboard engine today, many shops still do a good bit of two-stroke work. However, it won’t be long before that is completely replaced by four-stroke outboards.

“You can see less and less of them coming in every year,” Whetsel says. “They’re definitely transitioning to the four stroke or the E-Tec style engine, which is a two stroke, but it’s a direct injected two stroke, so it’s a lot more efficient.”

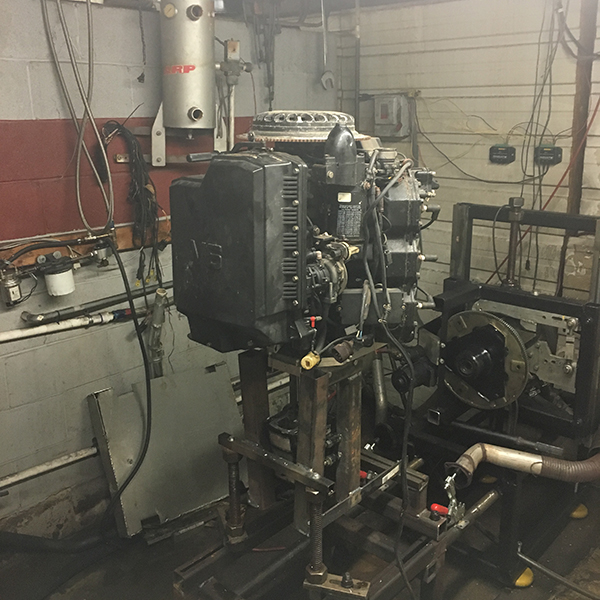

When RPM Performance gets an outboard engine in the shop for work, the job always begins with tearing down the engine.

“We generally see a lot of corrosion where we’re at in Florida due to the salt water, so we have to use a torch a lot to get things apart and sometimes you have to cut bolts off and pry and beat on things to get them apart,” he says. “Once we’re inside, again tackling that corrosion issue, we primarily use a soda blasting technique to clean out all the corrosion. It’s real gentle on the machine surfaces. It won’t actually remove any metal, but it does really good in removing the corrosion from inside the block and the coolant passages and all that.”

From there, the outboard goes through the same, basic procedures as far as rebuilding any engine. The shop generally bores and hones it, cleans it and puts everything back together.

“Some of the outboards, especially the Yamahas V8 stuff, come with the Nikasil plating, so that can’t be bored,” he says. “A lot of people are throwing those blocks away, but we’ve actually found that we can put a sleeve in it. We have to change the ring package to match the sleeve material. We can’t run the factory rings anymore, but we have found a way to fix those and keep them on the water.”

Keeping boats out on the water is the key to happy customers in this market. As much as that responsibility falls on the engine builder, boat owners too should know they need to have their engines serviced regularly to avoid costly issues.

“We’ve seen a few outboards come in the shop from detonation damage from running too lean,” Whetsel says. “People will leave the boat to sit all winter and not winterize it properly and then injectors are gummed up and don’t get enough fuel. We have seen that, but I would say 90% of it is corrosion. I have yet to see one that just wore out. They all have an early death from something else.”

Aside from some of those common issues, letting fuel sit for too long, or using ethanol, which can trap moisture, can result in outboard engine issues as well.

“Trapped moisture in the fuel, when left for too long, will cause the outboard to lack full performance,” says Vance Peterson, a Yamaha customer service rep. “The first thing we’ll ask is how old is the fuel in there? Use ethanol-free fuel and ensure that the fuel is always fresh.”

Making sure these outboards, like any engine, get regular maintenance from both the owner and a good engine shop is what helps keep them running for longer.

“I’ve had engines come in with around 200 hours, which is quite a bit, and they’ve been perfect,” Whetsel says. “I’ve had others come in that are only five or six years old and they’re just completely junk from all the corrosion. Most of that is how the owners take care of it and flush it out with fresh water and how often it gets used. Generally, the more often they get used, the better condition they’re in because salt water doesn’t sit in them too long.

“Using it is the biggest thing. Even if they can’t take the boat out, just firing it up on the hose every couple of weeks, or at least once a month to let water run through it and let everything run is probably the biggest thing people can do to save their outboards. There are a few products, like Salt Away, that you can run through to give it a real good cleaning and get that salt out. That would be a good idea if you are going to winterize it and let it sit for a while.”

Where Whetsel says he sees most of the problems in outboard engines is in the cylinder head because it is a water-cooled exhaust generally built into the cylinder head. Again, corrosion is the culprit.

“That’s where we see most of the problems in the four-stroke outboards, is corrosion, either at the head gasket line or sometimes they’ll just eat a hole right through the aluminum and start leaking water into the motor,” he says. “A lot of times we’ll have to replace the head or sometimes we can get in there and weld it and bring it back to life.”

Unlike the aftermarket that exists for parts and components for automotive engines, most outboards get refreshed using OEM parts, since that is what is readily available.

“On the two-stroke stuff, there are some aftermarket parts such as Wiseco and Vertex pistons, but on the four-stroke stuff it’s pretty much all OEM,” he says. “It’s few and far between that we can find aftermarket parts, which we try to do when we can to save the customer some money because OEM stuff is expensive, but it’s what’s available.”

Outboard Oiling

When comparing outboard engines to automotive engines, they’re actually fairly similar with some obvious differences.

“They’re pretty similar in as much as you’ve got a wet sump oil pump down at the bottom, there’s an oil pan down below the power head, there’s an oil pump that is driven by the crankshaft that moves the oil, pressurizes it, and pushes it up through the power head through the normal channels,” Meeler says. “The difference of course being that it’s a vertical configuration versus a horizontal configuration and the engine is designed so that when it is in a resting state, it will return the oil to the pan. There may be a slight amount of oil still on the cylinders if the engine is in a tucked in position to where the top of the combustion chamber is actually pointing slightly downwards, but that doesn’t amount to anything. The rings are designed such that they scrape that oil out. It does not get into the combustion chamber.”

One of the primary differences between outboards and automotive engines is in the oil itself. The oil used in outboards has its own special certification called FCW.

“FCW stands for four stroke water cooled and that basically dictates a minimum standard that marine oil must meet,” Meeler says. “It’s a certification put out by the National Marine Manufacturers Association (NMMA), which is the overarching organization for all of us engine builders.”

The biggest difference in outboard versus automotive oil is the amount of anti-corrosion involved in outboard motor oil/four stroke motor oil.

“The additives and things in that oil are different and stronger,” he says. “The molecular structure of the oil itself is enhanced by the additives that we put in it because an outboard engine works so much harder than a car engine – not only from the rpm standpoint – but also from a load standpoint. It’s nothing for an outboard engine to stay at 6,000 rpms for hours at a time. If you put conventional motor oil in an outboard, it’ll just rip it to shreds. It literally tears the molecules and it loses lubricity.

“Another thing that we have to do is introduce anti-foaming agents because of the rapid fire motion of what’s going on inside those engines at 6,000 rpm – you can foam a motor oil. If you do that, you’re going to lose lubricity, so premium marine motor oils will have additives in it to prevent that foaming from happening.”

To create a power plant built for high-revving rpms and lots of load, an outboard engine features a power head (the top of the engine) that is connected via a spline driveshaft that runs straight down into the lower unit, which is what some people call the foot. In there is a pinion gear, a forward gear and a reverse gear. Anytime that engine is running, the driveshaft and all those gears are moving. The way in which you shift the engine into forward or reverse is a device known as a clutch dog, which slides along the propeller shaft and engages either the forward gear or the reverse gear.

“It’s a very sudden engagement, and the amount of stress that is on the lubricant in that lower unit means it’s very specially designed to handle a tremendous amount of stress and also be able to handle a certain amount of water intrusion,” Meeler says. “If for any reason water were to get in there, the oil needs to be able to do its job without being compromised by a certain percentage of water.”

That driveshaft comes down, the pinion gear turns the forward and reverse gears and the clutch dog, which is spline to the driveshaft, engages one of those gears and turns the propeller in that particular direction.

“It’s a very simple system, but for a lubricant, it’s a pretty tough place to make a living,” he says. “The lubricants have to be top shelf in an outboard engine. Compromising on the lubricants in your outboard engine or your marine engine of any kind is not where you want to try to save a few pennies.”

Fueling the Outboard Obsession

The running joke in the marine industry is an outboard engine basically lives its life in first gear going uphill all the time. There’s no such thing as shifting gears. The amount of drag an outboard engine has to overcome is immense. For that reason, outboard engines are built very, very strongly.

“Yamaha is all about reliability,” Meeler says. “We take building the engines to a certain strength and reliability factor very seriously. The most recent engine we introduced, the XTO, was actually designed to be twice the reliability standards of all of our other engines. It’s just a brute – that’s one of the reasons why it weighs 952 lbs.

“Could we make 400 or 425 horsepower with a smaller engine? Sure, but it wouldn’t be as reliable and as durable as it needs to be. The XTO is just the classic example of Yamaha building to a durability standard and letting the weight fall where it may. We’re not trying to add weight, but we’re trying to build to a reliability standard and if that’s where the weight falls, that’s where the weight falls.”

Reliability and horsepower are certainly the cornerstones of outboard engines. Kyle Whetsel typically sees outboards that range in horsepower from 100-350 hp. According to Whetsel, Mercury just came out with a 525 hp V8, and a company called Seven Marine took an LS engine and bolted it to a ZF transmission, which is capable of 625 horse.

As far as the performance two strokes are concerned, a 3.0L outboard can produce 450-500 horsepower if it’s done right.

No matter the horsepower levels, boaters have the same mentality as racecar drivers – they want more horsepower and more speed. To remedy that, many outboard-powered boats today have two, three, four, and five-plus outboard engines.

“That’s definitely been the trend to put more and more engines on the back of the boat, which of course adds a ton of cost,” Whetsel says. “They have to have all individual rigging for everything. You need battery cables, batteries, battery switches, and the steering system is quite involved to tie all that together. Then, of course, you have all those propellers. There’s a lot more risk if you run a ground of damaging those and costing you a lot of money. Not to mention the maintenance too.”

According to Peterson, some boaters utilize the multiple outboard set up in case something happens to one of the engines or the props.

“Some people would rather have two twin 150s instead of a single 300,” Peterson says. “If something happens such as striking your prop on something, you have another outboard so you’re not completely out of luck.”

As outboard technology continues to increase, the experts say we’ll see less and less of the multiple outboard engine set ups and more of the big ‘Seven Marine-style’ engines.

The question is, what kind of engine is powering your boat? EB