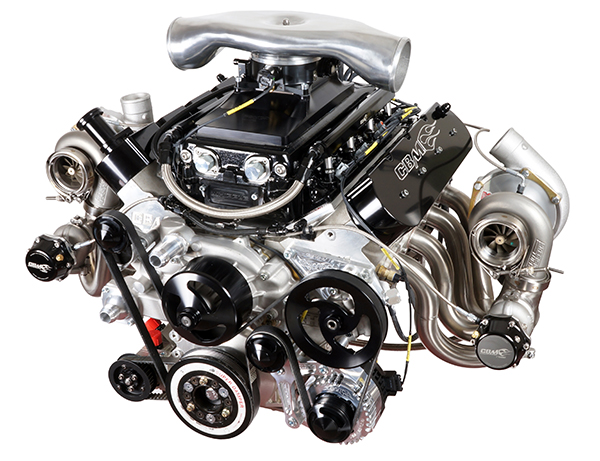

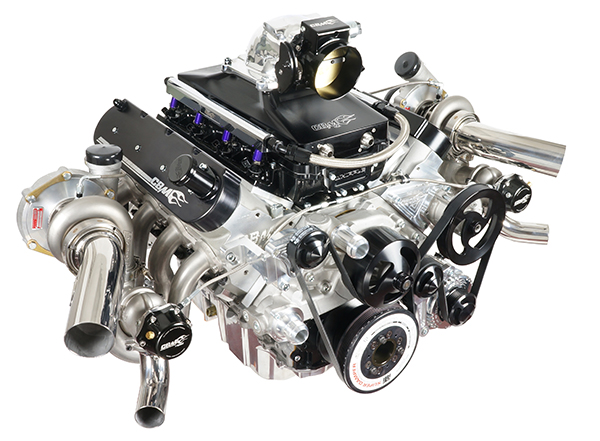

As an engine shop today, it helps to be diverse, and at CBM Motorsports, we continue to do just that. We continue to grow the marketplace with every aspect of the automotive world. Starting out in 2006, we primarily did engines for sandrails. Fast forward 16 years, we now do engines for drift cars, movie cars, street legal cars, Baja, Ultra4, sandrails, quarter-mile cars, track cars, classic cars, and more. Every build is an adventure to get the customers’ needs met.

How do we meet those needs? We do an interview as to the usage, the budget, the conditions, and the expectation the customer has for their engine and vehicle. The world of off-road race engines is a particularly tricky one in which every component choice has a large impact. However, we use these steps ahead of every build, regardless of application.

Let’s start with Ultra4, which races on some of the roughest terrain there is and these guys can flat out drive. For that reason, we really need to know how the driver drives (high rpm, low rpm, foot to floor, or ease in to it) as it helps us with our set ups.

One of the first things we figure out is the correct ring gap we are going to use, knowing that a stock engine with forged pistons is around .019˝ to a high compression engine and lager cubic inch being .021˝-.023˝. When you get to the boosted motors, we start at .026˝ and go all the way up to .032˝.

Oil pressures and oiling systems are another crucial thing to look at. We use a lot of dry sump systems to try to maintain even pressures because these trucks go up very steep hills and, if they were to use a stock oil pan, they risk running the engine out of oil. We utilize baffling systems to slow down the oil in the pans as well.

When it comes to bearing quality, we tend to run the Clevite brand as they seem to be very close in tolerance batch after batch, and because we set up our tolerances on the crank for every motor, it’s good to know they are consistent. Clevite has a standard bearing and a race bearing, as well as undersized and oversized options, so when setting up crank and rod tolerances you need all this information because we are only allowing .001-.002 per inch for clearance.

Another important aspect of these builds is valve seat pressure because this can vary greatly closed and open. A stock spring may only make 120-lbs. of closed pressure and 280-300-lbs. open. When you get into a dual spring, you could have up to 140-lbs. closed and 250-300-lbs. open. Some of the big aftermarket heads take a larger diameter spring, and if we use a solid lifter, the pressures will be up in the 250-300-lbs. closed range and up to 700-lbs. open.

The size of the camshaft is also a multiple task process, which includes determining how much lift you need (how open you want the valve), how much duration (how long you want it open), ramp rates (how fast you want it to open and close), and what lobe separation (the overlap between intake and exhaust).

After all that hard work comes the easy part, compression ratio and cubic inches. Cubic inches are a matter of what the owner wants or feels he needs and the budget he has. Once we get all of our answers, then we can start the build and put together what we hope is the perfect engine for the customer’s requirements.

When we get to the sandrail world, it again is different. Most sandrail owners know whether they want straight race gas or they want to stay on pump gas. If you are building a pump gas engine, we can tighten up the ring gaps and maybe drop a little more manageable camshaft in it for better mid-range duning. Customers have to keep in mind the range of a cams optimum performance. If you want really good power at 2,500 rpms, it will probably become less efficient around 5,500 rpms. If you want a cam to be efficient at 7,000 rpms, you will lose some efficiency down at 2,500 rpms, and probably be way better at 4,000 rpms.

Throttle bodies are another thing that is misunderstood – just because you can buy a bigger one doesn’t make it more efficient to your particular engine. If the throttle body isn’t asking for more air, you stand the possibility of causing drivability problems. A 76mm throttle body can handle efficiently up to about 500 hp. You may pick up a few horsepower (8-10 hp) from a 90-95mm throttle body if you are up around the 500-hp range. However, if you are around 400 hp, it might not increase any, but may cause a flat spot on acceleration or make it harder to tune to get it right.

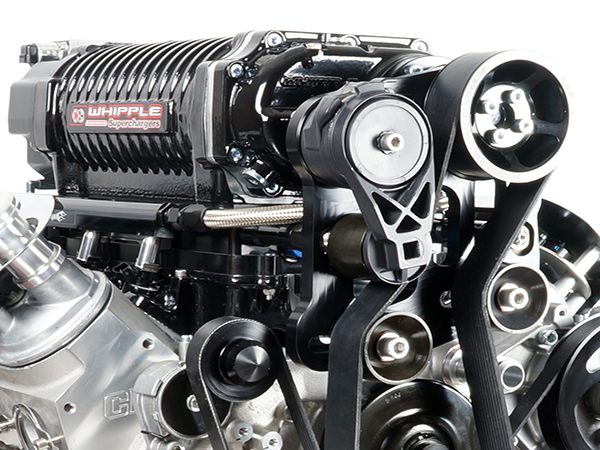

Boosted cars require the best parts and the engine is put through its paces, so crankshafts need to upgraded, rods need to be stronger, valves need to be better, and cylinder flow needs to be looked at carefully to make sure everything matches. We recommend a billet crankshaft for big horsepower and forged steel connecting rods. There are many quality manufacturers out there for these upgraded components.

We hear stories all the time about how my friend’s buggy made 800 hp and mine is only 600 hp, but I beat him every time and we weigh about the same. A lot may be the driver, tire size or ratios, but a lot has to do with building an engine where everything matches and works together, not just opening a parts book and ordering parts because they cost more or you like a particular brand.

In the Baja world, we do quite a few 6100 spec trucks that require stock crate engines because that keeps it even for all the racers and it becomes a driver’s sport. Typically, we always improve the stock oil pump with a higher volume pump as these trucks have large capacities, oil coolers and remote filters, and we need to make sure the oil travels well.

Most customers choose to upgrade balancers at the same time before we get the engine sealed for the race. These are about the only things that are allowed in the rule books for 6100 spec – no performance modifications are allowed.

Trophy Truck racing goes along similar lines of Ultra4. These trucks take a beating and most, if not all, run race fuel, high compression and big cubic inch engines. We have a few running upwards of 800 hp with 8 stacks, MoTec computers and MoTec dashes, which is a pretty big ticket.

One thing these big engines need is air, so it is very important to put the air filter someplace where it gets the least exposure to dirt or you need to oversize the filters if you have no choice but to leave them exposed. As in Ultra4 and Baja, the main accomplishment is to finish, but it’s always nice to win. Having the right engine matched with the right components (and a sturdy vehicle) is the key to having success off-road. EB