Most of us are familiar with the Enzo Ferrari quote, “What’s behind you doesn’t matter.” We can all agree the man responsible for these iconic words knew a thing or two about racing. His quote speaks to many of us, on many levels, and it’s the reason we’re driven to always do things better.

Finishing first is the name of the game, and that pursuit happens both on and off the track. We’re always trying to make more power and make our engines as bulletproof as possible. Part of that equation comes from piston manufacturing and technology.

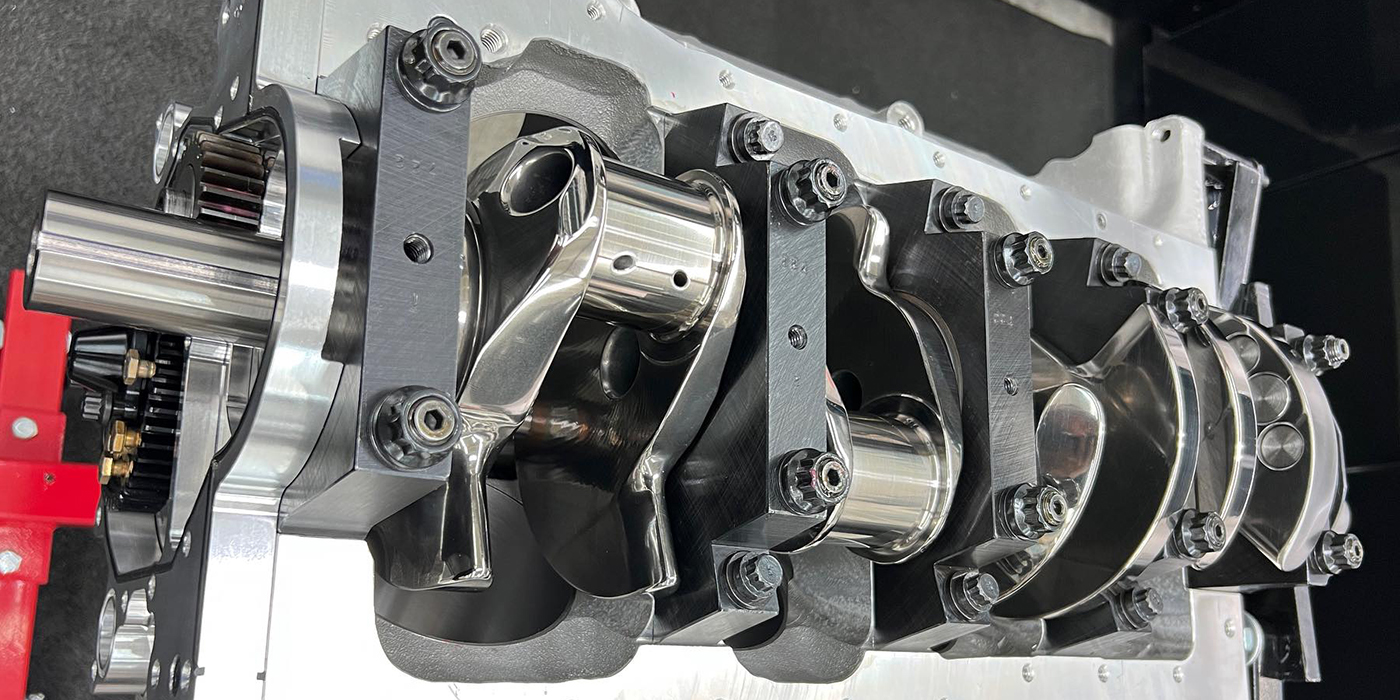

Perhaps one of the more sophisticated chunks of metal in the picture, you better bet that material makeup is an important part of the snapshot. Today’s piston materials commonly include 2618 and 4032 aluminum alloys, renowned for their lightweight properties, high strength and excellent thermal conductivity.

According to Michael Panetta at Diamond Pistons, these alloys offer durability and performance benefits, particularly in high-performance and racing applications, where weight reduction and heat dissipation are critical factors. In fact, there are many reasons these materials are popular.

“2618 and 4032 remain the most common in the racing community, with 2618 having better mechanical properties (i.e. tensile strength) and fatigue life, especially at elevated temperatures,” says Trip Manley of Manley Performance. “4032 is typically utilized for lower power, less stress applications where tighter PTW (piston-to-wall) clearances are desired as it expands a bit less than 2618 due to the silicon content.”

When a material works, that’s what everyone uses. In the case of CP-Carrillo, 2618 is used primarily as it’s considered the optimal aluminum for racing pistons.

“With less than 1% silica, it’s a purer aluminum than other piston aluminums out there, but we have manufactured parts out of other materials for R&D, testing and OEM applications,” says Cindy Verkooij, director of sales and marketing, CP-Carrillo.

While the piston material is a key component of the manufacturing process and is application specific, the increasing presence of piston coatings has helped durability immensely.

“The most common piston coatings include anodized, moly skirt, and ceramic crown coatings,” Panetta says. “Research in this area is prevalent, with ongoing advancements enhancing durability and performance.”

The research in this category is more related to application on the piston and making sure the adhesion is superior, along with being able to apply it quickly and accurately.

“We like to design our skirts in a way that encourages oil retention on the piston, so no additional coatings are needed,” Verkooij says. “Still, dry film skirt coatings and ceramic top coatings are offered upon request. WPC is also a popular option as it treats the whole piston, not just one part.”

WPC is a treatment that enhances the piston surface to reduce friction. By firing ultra-fine particles toward the surface, the thermal discharge permanently changes it, strengthening the structure and creating a harder, more durable product.

Just when it seems as if nothing can change, such as with manufacturing technology, you realize there’s always a new angle.

“There have been notable advancements in piston manufacturing technology,” Panetta says. “We are actively engaged in ongoing research and development efforts aimed at refining the manufacturing, engineering, and fixturing processes involved in piston production. Our relentless pursuit is focused on pioneering innovative methods to consistently deliver top-tier forged pistons that set new benchmarks in the market.”

It doesn’t look like there’s going to be any slowdown in this trend, but it may be one of the more slowly growing ones.

“Manufacturing technology is constantly evolving,” Verkooij says. “Processes for reduction of operations, better fixturing and quicker cycle times is always a goal, but with the machine options, tooling and work holdings currently available, it’s a fine balance between keeping up with the demand and making improvements.”

Billet is just one of those words associated with performance, no matter how you stack it, but it has its pros and cons. While forged pistons are the strongest, billets provide greater flexibility in manufacturing since material can be kept wherever necessary in the design.

“Billets offer a distinct advantage when a ‘good forging’ is not available, or a new design concept is being determined,” Verkooij says. “Billet piston design gives you a blank canvas, but yields increased cost and spindle time. Billet pistons are more and more common in the industry and are made of the same materials that our forgings are made from. The flexibility is a nice option to make sure the piston is not heavier than desired and provides an opportunity to potentialize the part in all aspects.”

Everyone wants to make their pistons last as long as possible, but is failure always the piston’s fault? According to Diamond’s Panetta, common avoidable reasons for piston failure include insufficient lubrication, incorrect installation, neglectful maintenance, overheating and fuel contamination.

“Proper measuring and blueprinting during the engine assembly process are essential for averting such problems,” he says. “Common piston installation mistakes include incorrect piston-to-wall clearance, improper preparation of cylinder bores and incorrect ring gap settings. These errors can lead to compromised performance and reduced durability.”

Some problems, however, may arise after an engine is fully assembled and has been running, such as improper tuning.

“Many people think because they are not running very big horsepower numbers that the piston will survive engine modifications without proper tuning,” Verkooij says. “In reality, combustion temperatures can melt aluminum very fast, and the reason they survive the extreme environment is because the quantity of fuel and air are combined at just the right amounts and for just the right amount of time to make the power before they are quickly forced out of the cylinder and out the exhaust. If any of those factors is not calibrated correctly, the piston will be exposed to heat for too long, potentially causing detonation, pinched rings, scored cylinders, melted pistons or any combination thereof.”

Proper assembly is one of the biggest factors, that if done incorrectly can spell disaster. A large influx of do-it-yourselfers over the last decade putting together their own engines has been part of that trend.

“Although we applaud the hands-on mentality and desire to expand knowledge in the artisan field of engine building, there are so many things that can go wrong and can ruin a big investment,” Verkooij says. “We’ve seen so many ruined parts over the years from ring butting. Either customers didn’t file the rings enough for their horsepower, usage, or tune-up, or they simply assumed everything in the box is ready for install.

“Piston rings typically start with a tight gap out of the box, to accommodate customers with low NA horsepower numbers that prefer a tight gap, or for cylinders that are honed a little oversize from the original intended bore size. They always need to be checked and most likely filed to your engine’s needs. CP-Carrillo provides general guidance for this, but because every engine is different, every cylinder head flows differently, and every racing scenario can play a part in deciding proper end gaps. An experienced engine builder in your exact application can provide expert feedback.”

Another area of common failure is the pin lock failing or scuffing. Lock failure can happen when a lock is not properly seated in the piston, or when the “end play” of the wrist pin (when installed with locks) is not adequate.

“Typical end play for CP-Carrillo is between 0.015” and 0.020”,” Verkooij says. “Scuffing caused by an end user can be due to an abundance of fuel, which washes the cylinder walls down, reducing the hydroscopic layer of oil that needs to be on the cylinder to lubricate the piston and rings during operation.”

Piston installation requires verification of fitment and clearances. Although everyone should be able to rely on the machine shops and manufacturers, it’s always the responsibility of the builder to ensure these clearances are what they should be. Piston-to-head, piston-to-wall, ring groove clearance, wrist pin clearance, end play and a variety of other key features should all be checked, just like any other aspect of the engine.

When it comes to selecting pistons for your application, many factors should be considered such as material composition and ensuring it aligns with the engine’s intended use.

“The design should cater to achieving the desired compression ratio and combustion efficiency, considering factors like piston shape, dome configuration and skirt design,” Panetta says. “Emphasize strength and durability to withstand high loads and stresses, especially in high-performance or racing applications. Balance weight reduction for improved engine response and acceleration with maintaining structural integrity. Additionally, explore coatings like thermal barriers or friction-reducing treatments to enhance performance and longevity by mitigating heat transfer and reducing friction.”

Cost and time are also important factors in an engine build, which can change the outcome. If cost is not the primary concern, that opens up a large window for options. Time is not only seasonal, but it’s also determined by the complexity of the design.

“Will it take a lot of engineering effort, does it take a long time to program and produce in the manufacturing facility?” Verkooij says. “Category and/or sanctioning bodies also determine what you can use, rules, component weight, etc. If you have no rules to follow and have the ability to order anything you want, it is then up to you and the supplier to make sure you know what options you have, how long it will take and what it will cost. Most high-end engines today require some engineering time and a variety of 3D milling, which incurs additional time and cost. Our goal is to be transparent and supply the best part possible for the application.”

What’s in your engine matters, so you don’t have to worry about what’s behind. EB