There is a lot of information out there about engine bearings, so I figured I’d try to set the record straight about a few things related to this tiny, but significant, engine component. Obviously, multiple factors affect bearing performance in an engine, and the experts agree the first step is knowing what the end use of the engine will be. Racing bearings are different from those recommended for street use, and there’s a lot to consider. In the end, only the combination of all factors will yield the answer to the question of bearings.

Rigidity of Components

Many times, I’ve heard the discussion of setting up an engine “loose” or “tight,” referring to bearing clearance, and “loose” often represented as a benefit because the engine spins “easier.” But, the bottom line is how much crank flex are you going to have? “If you get a lot of deflection, then setting up an engine looser is beneficial,” says Ron Sledge, performance and technical manager of King Bearings. “If you have a crank that wants to bend, you can’t set the clearance up tight because the crank will get into the bearing. Your crankshaft is probably the most crucial thing to cause wear because of deflection. If it’s bending, the crankshaft journals will be out of line and if clearances are really tight, you’re more likely to touch a bearing.”

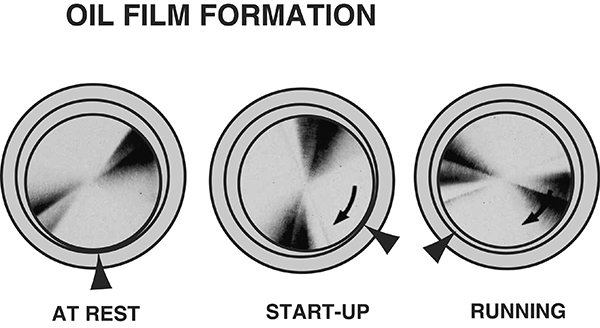

The primary focus of rigidity in this aspect is the crankshaft and factors that can affect it. Extending similar advice is Dan Begle, technical sales engineer at Mahle, who says, “Building an engine with extra clearance is done because of power adders such as nitrous. In these situations, your limiting factor becomes the crankshaft. When the crankshaft is under severe stress, it causes the crankshaft to flex. When it flexes, your oil clearance is smaller than what you set it to. The crank begins to orbit, which means it isn’t running on its centerline. The extra clearance is so you can still create an oil film when the crank is in an orbiting motion, so you don’t have bearing to journal contact.”

Oil Clearance vs. Viscosity

A close tie-in to the previous category, oil clearance and viscosity go hand in hand. “You need to match oil clearance with oil viscosity,” Sledge says. “If viscosity is not enough, oil can flow through the bearings too much where you don’t maintain a strong oil film. Maintaining a good strong oil film between the bearing and the crankshaft is the key to not having any trouble. If I’m going to run .005” clearance, I’ve got to run a 50 or 60 weight. If I’m going to run a .002” or .0015,” which is what some OE clearances are these days, then you need to run a 20w or less. The oil has to be thin enough to get in between, but thick enough to maintain the oil film.”

How important is all that? Robert Taylor of ACL puts it bluntly by saying, “The thickness of the oil film is the difference between you having a crankshaft and not having a crankshaft. If they don’t match clearance and viscosity, do you want to take that chance?”

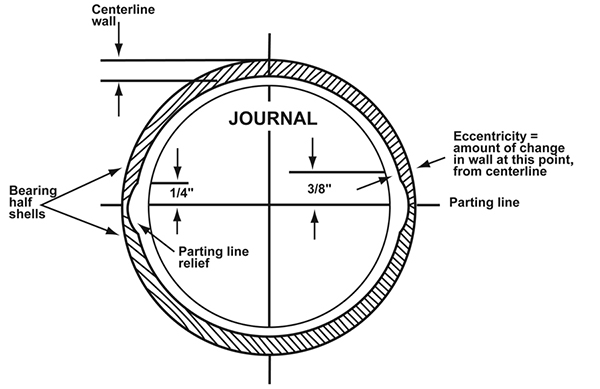

Bearing Eccentricity, Oil Pressure and the Oil Wedge

Bearing geometry is a fascinating aspect of this all, as the I.D. of an engine bearing is designed with a certain amount of eccentricity, which acts to build an oil wedge and maintain the oil film across the bearing surface. “The bearing is a mechanical oil pump,” Begle says. “The eccentricity designed into a bearing is relative to the hydrodynamic pressure developed. The outer diameter of the bearing is perfectly round,” Begle says. “On the inside, at the 12:00 position, where you measure oil clearance, is the tightest spot. At about 45-60 degrees [from vertical, the bearing wall thickness] is thinner. At the very end where the bearings meet, this is called the bore relief. It is the thinnest to protect from any deformities in assembly or during operation.”

But is the geometry the same for all bearings? “The action of the crankshaft will create a hydrodynamic oil film,” says Mark Shadbolt, ACL product engineer. “In our performance race series, we build more eccentricity than in a general replacement bearing, and the other reason for eccentricity is because it allows for distortion in the whole system. You get much more distortion in a race engine.”

And do the experts all agree? You bet. “The difference between a replacement and a performance bearing is the wedge,” Begle says. “A performance bearing has more wedge to try to create a higher film pressure to try to keep the journal off.”

To add more pieces to this puzzle, there are low eccentric bearings and high eccentric bearings, depending on the application and how rigid the housing is that it goes in. “For example, if the big end of a rod isn’t rigid enough, at high rpm the bearing will elongate,” Sledge says. “More eccentricity will be required because as the bore becomes egg-shaped, the bearing pulls in, and you need more room to maintain the oil wedge. If the bearing bore elongates and closes the clearance, then the bearing will wipe the oil off. A stronger rod needs less eccentricity.”

You might be wondering, where does oil pressure fall into all of this? It’s a small piece of the puzzle. “A spinning journal inside a bearing with oil present is the oil pump of the engine,” Sledge says. “The oil pump’s job is just to keep oil at the journal. As the crank spins faster, it uses more oil. The pump just needs to keep oil supplied. The eccentricity and wedge pulls the oil through. More pressure than what’s needed is just going to bleed off and rob horsepower.”

Loading Duration and Bearing Fatigue

Loading duration is an important factor because it determines the type of bearing you’ll need to use. “The worst thing that can happen to a bearing is fatigue,” Sledge says. “If it fatigues it’s going to self-destruct. On higher duration/loading motors like marine or endurance racing, the crank will put so much load on it that it causes cracks. Fatigue can be in two levels. It can be the base material, or the overlay material and you build the engine to avoid fatigue.

“Even if a streetcar has an engine that produces 700 or 800 horsepower, the load is not very high for very long. If I’m going to drag race that street/strip car, the load is still very short, but if I’m going to load the engine like a circle track or marine engine, then we have loading for long periods of time, and that high duration is conducive to causing fatigue. Loading duration is how the bearings are separated.”

Bearing Construction and Failure

“A typical performance bearing is a tri-metal bearing with a steel backing,” Begle points out. “The middle layer of the tri-metal is copper, tin and lead, but at Clevite, it’s melted together in a molting process. At that point, you take the two elements of copper and tin and make an alloy of bronze, so you create a grain structure. Other bearing companies use a sintering process, so no grain structure is created.”

Just as a forged crank has a grain structure that makes it strong as opposed to a casting, Clevite performance engine bearings are made the same way. Greater strength is created by combining the elements into an alloy of bronze, copper and tin, with the overlay on top. You don’t see the center, only the back and overlay.

“The overlay is an electro plating process of copper, tin and lead,” Begle says. “It’s controlled to create a certain thickness.”

On the deepest level, what causes a bearing to fail? “When you don’t have proper oil clearance and the journal comes in contact with the bearing, it creates frictional temperature on the overlay,” Begle says. “The melting point of tin is 449 degrees F, so when you get frictional temperature, you start to melt away the tin plating in the overlay, and you start to destroy the bearing. Frictional talk is strictly about the overlay, and the substrate has the load carrying capacity.”

Embeddability

Embeddability refers to a bearing’s reaction to contaminants in the oil. Good embeddability means the bearing material has the ability to trap foreign particles and sink them beneath the surface. “Cleanliness is key,” Taylor says. “You want debris to embed into the bearing. The alternative is that it scratches the crankshaft journal. There is always going to be debris. Do you want to change the bearings or change the crankshaft?”

The subject of embeddability leads to the subject of compromise. “At the end of the day, bearing materials are compromises,” Sledge says. “You give up one thing to get another. For a daily driver, you want an engine to last a long time and you want a bearing that has good embeddability.”

Aluminum bearings, typical for general replacement bearings, have good embeddability which allows them to handle a larger amount of debris, but there’s a sacrifice with hardness and loading capacity. “Any good bearing material is a compromise between strength and embeddability,” Shadbolt says. “All bearings have a certain level of embeddability built into them, but race-series bearings have less. Pay attention to cleanliness.”

Bearing Conformability/Deformation

Conformability or deformation refers to the ability of a bearing to adapt to any geometrical misalignment of its housing or journal. Poor conformability can cause a reduction of the oil film thickness, leading to bearing wear. “If the bearing is not deformable, it’s not going to match the shape of the housing, and the bearing has to move with the housing,” Shadbolt points out.

Coatings

These days, many performance bearings feature an optional coating, which can often be thought of like buying insurance. “The coating is a non-metallic layer,” Sledge says. “Without the coating, you get metal-to-metal contact. You can get metal-to-metal contact on startups, or if you have some issue with oil pressure. The coated bearing will survive longer because the polymer layer will slide over the crankshaft easier than metal. Two metals want to grab each other.”

According to ACL’s Shadbolt, a coated bearing’s advantage is lubricity, and it protects the bearing in extreme situations.

The Last Word

The experts all agree that cleanliness is the most important factor during installation, and the lack thereof is the most common problem that leads to bearing failure. But measuring is just as critical. Taylor points out a common mistake is assuming that a new crankshaft is the size that it’s supposed to be. “Assuming is a big mistake,” he says. “Don’t assume anything. Always measure, measure, measure.” EB