Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

Valve Seal Removal

For removing the top hat valve stem seals on heads with bucket holes hard to reach, I use stripped sockets the right size, with an extension. Knock it to grip and use a battery-operated ratchet to spin the seals out. It takes only a second per seal.

Sylvain Tremblay

Les Ateliers de Moteur-Competi-tech.

Ste- Catherine, Quebec, Canada.

Blasted Tools

I always keep a pair of needle nose pliers and a small, straight screwdriver in my blast cabinet to hold small parts when blasting. It saves the problem of frequently replacing a glove with a hole in it and having to chase parts around the cabinet.

Lee Johnson

Pro Performance

Phoenix, AZ

Assembly Lube

I keep a container of engine assembly lube at my cylinder head work bench. A good dab of assembly lube holds spring cups or shims in place during cylinder head assembly. Too many times the shims came off and got mixed up, so I started doing this and the problem was solved. I found it simple and certainly helpful.

Randy Torvinen

Torvinen’s Machine Shop

Menahga, MN

Clean Insert Install

I made this tool to install slotted drive thread inserts. This is for when you want to run them upside down for a cleaner install, and to recess them. The alloy DOM tube is turned down to fit the tapped hole. Drive them in and simply loosen the bolt and back it out. Works great for main thread repairs where you want the anchor a little below the surface. It gives a cleaner look without needing to spot face the drive lugs.

Ron Flood

Cedar Machine

North Branch, MN

Easy Set Screw

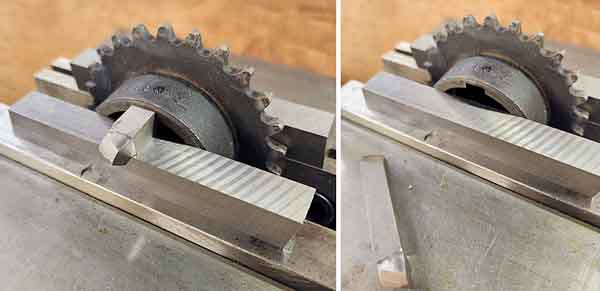

This is an easy way to align a pulley or sprocket when drilling and tapping for a set screw on the key. Suspend the pulley (or sprocket) on a length of key stock, supported by vise jaws. Tighten the vise to secure the pulley. Center over the keyway by probing or edge-finding both sides of the key stock. Slide the key stock out to remove before drilling and tapping pulley or sprocket for a set screw. 1-2-3 blocks can be used atop the vise jaws to accommodate larger diameter pulleys. Also, a variation of this technique can be used to align the pulley for a set screw placed 90-degrees to the keyway.

Tom Nichols

Automotive Machine & Supply

Cleburne, TX

Preventable Lifter Clatter

The lifter oil feed hole on common GM LS lifters is offered in more than one orientation. Both are functionally correct and interchangeable. The difference is in the location of the oil feed hole. Both should be installed such that some oil will always remain in the lifter after the engine is shut-off to help prevent lifter clatter when the engine is restarted. This is not an issue with both designs, as one has side oiling and can be installed with the hole pointing in either direction. The other, the traditional GM roller lifter used for many years in Chevrolet V8 and V6 applications, must be installed with the oil feed hole pointing up towards the intake manifold. If installed with the oil feed pointing down towards the exhaust manifold, oil will bleed out and the lifter may clatter until sufficient oil pressure is present to refill the lifter.

Engine Pro Tech Committee with Elgin Industries.