Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

Lifting Heavy Crankshafts Safely

We found placing cranks, whether light or heavy, can be difficult to do in a hot tank pressure washing stand. This can be even harder to lift after the crank is washed and hot. To protect the machined surfaces and make it safer, pick up and move crankshafts in an upright position. We use pieces of pipe or tube with the inside diameter needed as a safe locking devise along with a small serpentine belt. You can have one for dirty cranks and one for the clean cranks.

Perry Redeker

RPM Racing Engines

Wausau, WI

Single Exhaust Vacuum Checking

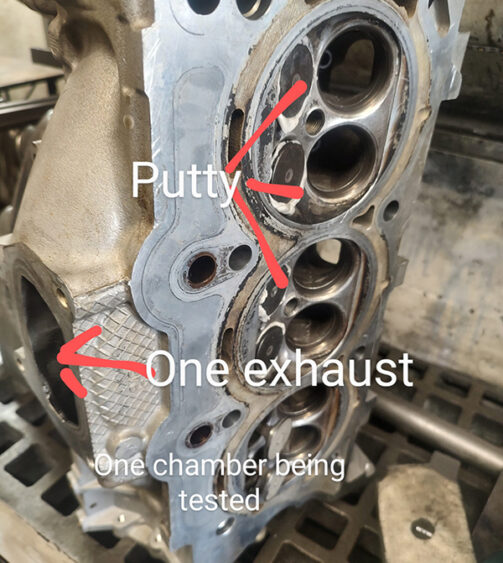

If you’re like me, you test all the valve-to-seat seals with a vacuum test. It’s not possible when you have a single exhaust system. What I use is plumber’s putty on the valves of the chambers not being tested to assure a good seal. It also doubles as a way to find any existing leaks.

Luis Guzman

Technomotors

El Paso, TX

Oil Bottle

We modify small plastic bottles, purchased online, for cutting oil, tapping fluid, assembly lube, etc. We’ve tried bottles with dispenser tips, however those with metal “needle tips” can scratch parts, while the plastic tips are usually too short, or dispense too much and cause excess usage and waste. Instead, we drill the plastic bottle lids so the “straw” from a spray-lube can fits tight. It dispenses the perfect amount, has a safe reach for use on the lathe or mill, and won’t scratch parts.

Tom Nichols

Automotive Machine & Supply Inc.

Joshua, TX

Modify as Needed

Many times, the flange diameter of the rod nuts will contact the radius around the nut seat on some rods. Some jobs may not warrant the expense of spot facing the nut seat on the connecting rods. In that case, it can be quicker and more effective to just machine a chamfer on the ARP rod nuts.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

Narrowing Bearings

When I need to narrow a set of rod bearings, I have bucks that I’ve turned to the size of the crank pin. Then, I wrap a single layer of masking tape around them to protect the bearing. I hold the bearing to the spud with a couple hose clamps attached end-to-end and use two seems to snug up better than a single one. If the buck is a specific width, it’s easy to use that in conjunction with where the tool bit touches it to get the bearing width dead on.

Ron Flood

Cedar Machine

North Branch, MN

Noisy, But Not Always Defective Lifters

Hydraulic valve lifters are the most precision machined part inside any engine. It does not take much to cause one to operate incorrectly. In this case, we’re talking about lifter noise and or a lifter that does not hold oil pressure and is unable to carry the pushrod properly through the full rotation around the cam lobe.

Noise from the lifter or valvetrain can come from something as simple as low oil level in the engine. Momentary lifter noise when an engine is started up is normal if the noise goes away in a few seconds. If the noise persists, oil level may be low in the engine allowing the oil pump to pump air into the oil galleys and into the lifters. An overfilled crankcase can also cause noise. The crankshaft counterweights can churn the oil into foam. When foam is pumped into a lifter it will be noisy. A damaged oil pan, or a loose or cocked pickup screen can also cause an oil pump to pump air to the lifters. Noisy operation at higher engine speed and little or no noise at low speed can be a sign of air in a lifter.

A noisy lifter at idle to 1,500 rpm, may be caused by a worn or scuffed valve tip or rocker arm face, excessive valve-stem-to-guide clearance, excessive valve seat or valve face runout, or a valve spring that is out of square. Worn pushrod tips or rocker ball seats can cause a continuous noise no matter what the rpm. This is very common on roller lifter engines where the pushrods and the lifters are not rotating. An intermittent noise that goes away with increased engine speed is usually caused by dirt. This may be due to poor maintenance, or from a newly rebuilt engine not cleaned properly before reassembly.

There can be such a thing as a defective lifter, but there are several conditions that can lead to lifter noise, and these should be checked before just throwing another set of lifters at any noise problem.

Engine Pro Tech Committee with thanks to Federal Mogul Corp.