Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

TAPE MEASURE

In most cases, when I top down a sleeve, I put a piece of masking tape next to the sleeve. The tape I have is .005″ thick, so when my tooling touches the tape I have right around that .005″ left to file if I’m not decking. If you have fine feed with an indicator, you can take it a bit closer safely, after hitting the tape.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

LINE HONE QUICK CHANGE

On my line honing machine, I machined the threaded hold down rods for 3/8” cap screws. This makes adjusting them much faster, using a cordless drill. Just machine the face flat, and drill and tap on the lathe. It’s a super time saver when switching from mains to cam tunnels and you have to adjust them a long distance.

Ron Flood

Cedar Machine

North Branch, MN

CLEANING 3-JAW CHUCKS

This is a quick and easy way to clean 3-jaw crankshaft grinder and lathe chuck scrolls.

– Make a stubby chuck key driver for use in a cordless drill; quickly remove the jaws.

– Insert a toothbrush in one of the jaw slots, then run the drill-driver to spin the scroll while spraying carb cleaner on it. Repeat as needed until scroll grooves are clean.

– Clean and coat the toothbrush with oil; insert the brush in a jaw slot and spin scroll with drill-driver until grooves are lubed.

– Use drill-driver to replace jaws.

Tom Nichols

Automotive Machine & Supply, Inc.

Joshua, TX

SWEETER THAN HONEY

We can all relate to trying to remove a nut that is well bonded to a stud. You have heated the nut to glowing red hot and it will move, but it is snapping, and you know you’re going to break the stud. What do you use for penetrating oil? Oils just turn to smoke and flame. Enter the humble bee. Beeswax is a superior high-temp penetrating lube. Touch the heated part with beeswax and it will flow through the threads and presto, the nut comes off.

Peter vanSneidern

Kidder Mtn Restoration

Temple, NH

TIME AND BACK SAVER

We all know the older we get the smarter we need to work. Plus, we have to take care of our backs. I designed a simple lifting hook to move engine blocks with, plus it works well to grab the turn table of the jet washer for easy removal access from the machine.

Hillsboro Racing Engines

Bruce Serene

Hillsboro, KS

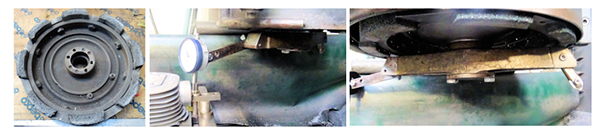

SURFACING QUICK CHANGE

I have made a quick-change for going between surfacing aluminum and cast iron heads. For aluminum heads, I use a PCD plate and 750 tr/min on an arm with 2-strong bolts with guiding in a stone head. For steel, I use grinding stones and 1800 tr/min with water cooling. I also made a measuring tool to set the head flat.

Joris Deckers

Motorenrevisie

Belgium, EU