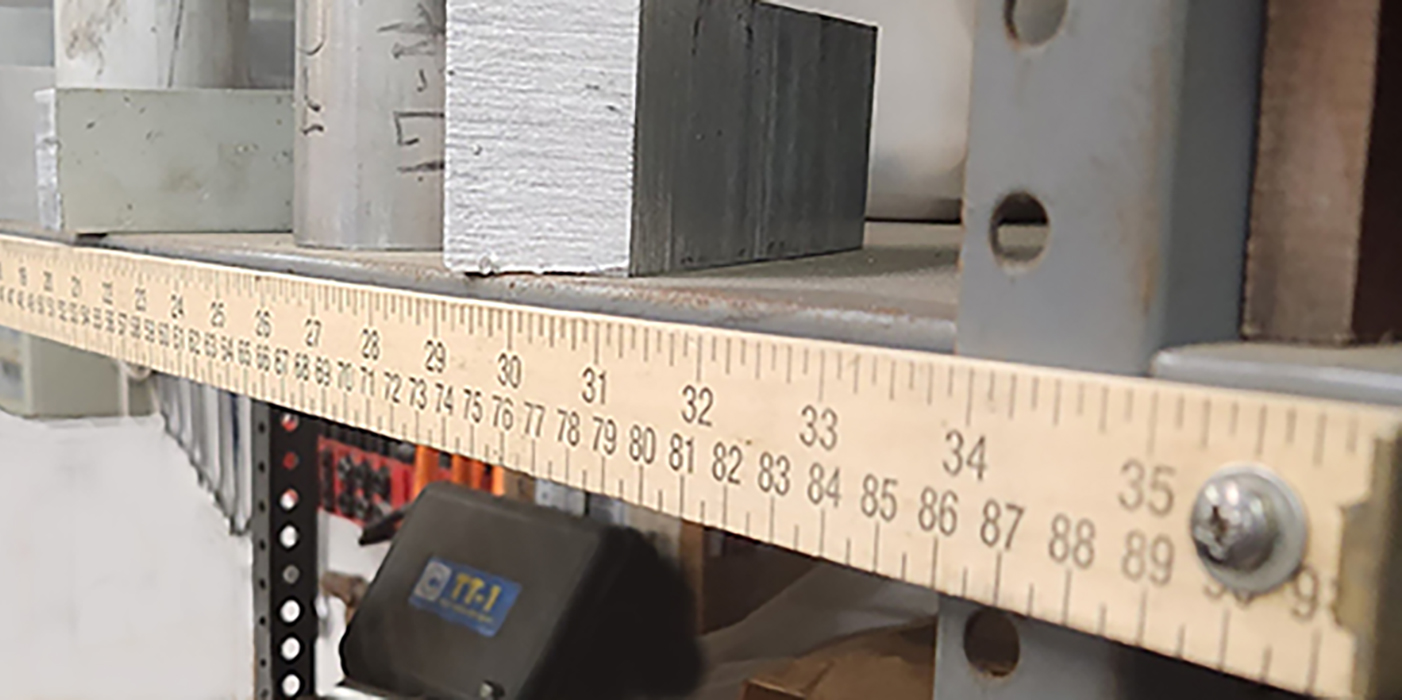

QUICK VALVE SPRING CHECK

For a quick check or if I don’t have a spring height mic that is small enough, I use a telescoping gauge to get the height off the head. Then I have various valve adjustment discs I use to simulate the retainer thickness and I don’t have to re-adjust the snap gauge for the retainer thickness. I just set the gauge on the disc.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

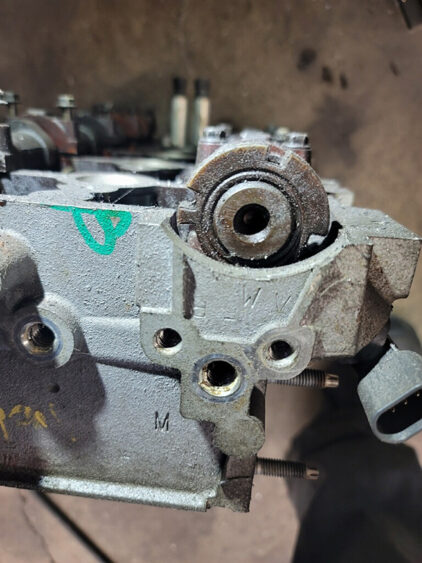

CAM RELUCTOR WHEEL BLUES

On the 2006-2016 GM 2.4L EcoTec engines, beware of the reluctor wheel attached to the intake and exhaust camshafts for the cam sensor. These are just pressed on. If they get hot and lose their press fit, they will come loose and move. The engines will run poorly and throw codes due to the timing being off on these sensors. It appears the camshaft(s) need to be replaced to fix this.

Steve Buege

Buege High Performance Engines

Burnett, WI

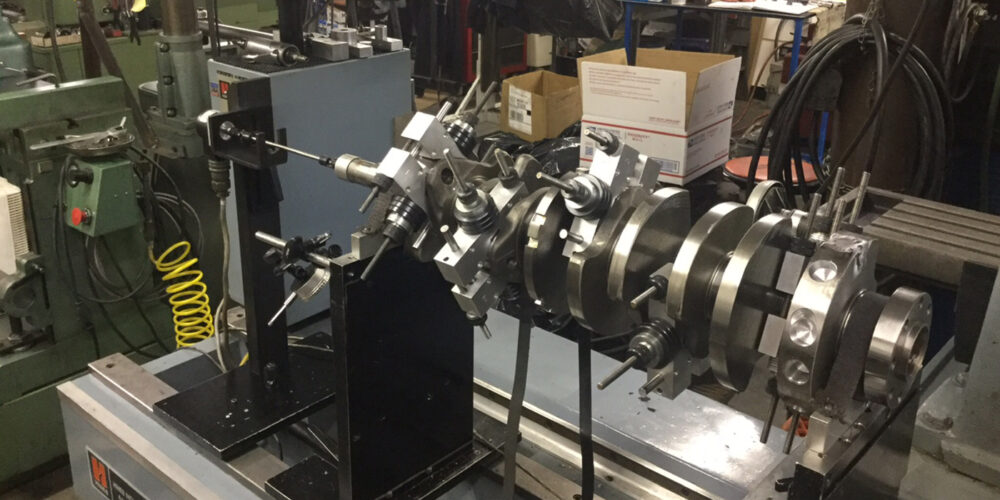

V10 BALANCING ACT

When balancing V10 cranks, I use my four V8 bobweights and then two V6 bobweights on the fifth journal. I’ve double checked this by moving them around after the crank is balanced, and there is no change. It works great and eliminates the need to purchase another V8 bobweight.

Ron Flood

Cedar Machine

North Branch, MN

GEN VI LIFTER GUARD

I have a big block Gen VI tip that will provide oiling and windage improvement at no cost. When a builder uses retrofit roller lifters and no longer has a use for the hold down spider, I find it useful as a cover and shield by modifying it and adding dimples for oil to run off near the lifters. It acts like a safety shield if a pushrod breaks or bends and keeps it from falling into the camshaft. Any oil “catch” and windage may also help with the cam wear.

Rich Franzman

Rich Franzman Racing Engines

Lake Elsinore, CA

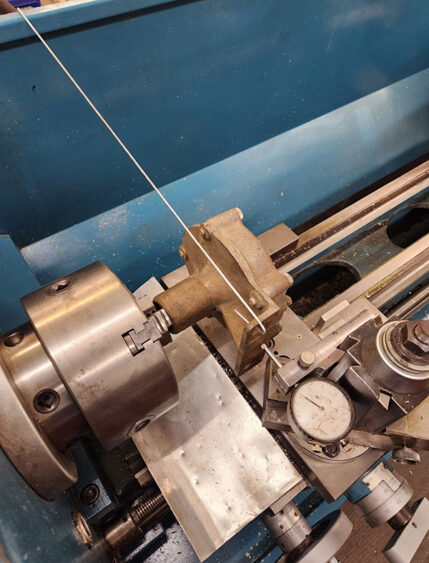

IN HOUSING SHAFT REPAIR

Let’s say you need to repair damaged threads on the impeller end of a pump or turbo shaft, which is recessed in the housing, and maybe even mushroomed by a hammer-happy tech. You cannot remove the shaft from the housing because of the mushroomed end or maybe you can’t get new bearings or seals; and you don’t want to disassemble it. You need to center the shaft in the lathe, but obviously cannot center off damaged threads and no bearing surfaces are available without disassembly. Disassembly and re-assembly can add extra time to the job.

You can center the shaft and machine it as an assembly.

– Mount the driven end of the shaft in the lathe’s 4-jaw chuck.

– Prevent the housing from rotating with the shaft by tying a length of wire to the housing and anchor the other end to the lathe’s back-splash shield. The wire needs to be somewhat flexible up, down, in and out, so don’t tie it too tight. I use 1/16 aluminum TIG filler rod.

– Place an indicator against a suitably smooth area on the housing, first near the chuck and dial it in as you normally would and then repeat with the indicator closer to the damaged end.

I’ve used this time saving method to successfully repair dozens of generators and alternators, turbos, and industrial pumps as shown in the picture. It can be a real money-maker.

Tom Nichols

Automotive Machine & Supply, Inc.

Joshua, TX