Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

End Play

Setting crankshaft end play on engines that you do frequently can be made quicker easier. If you do enough engines, you will always find yourself lapping thrust bearings to get desired end play. Start recording the width of thrust bearings after you have lapped them and achieved the end play you like. Keep these measurements in your notes. If you prep the bearings before final assembly, you won’t have to play the “crank thrust games” when everything is lubed up and ready to assemble.

Nick Jones

Automotive Machine

Fraser, MI

Mini Protractor

Sometimes a machinist’s protractor is too cumbersome in cramped spaces to compare angled surfaces on a part. A feeler gauge set works very well as a protractor in tight spots. Modify the gauge by adding a screw and nut to lock it in position.

Tom Nichols

Automotive Machine & Supply, Inc.

Joshua, TX

Shim It

I make a spacer to set in the recess of my height mics for small retainers. I use two .060″ and one .030″ spring shims and I can use it on SB Chevy heads and others with small diameter springs. The A & B 105 work for SB Chevy.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

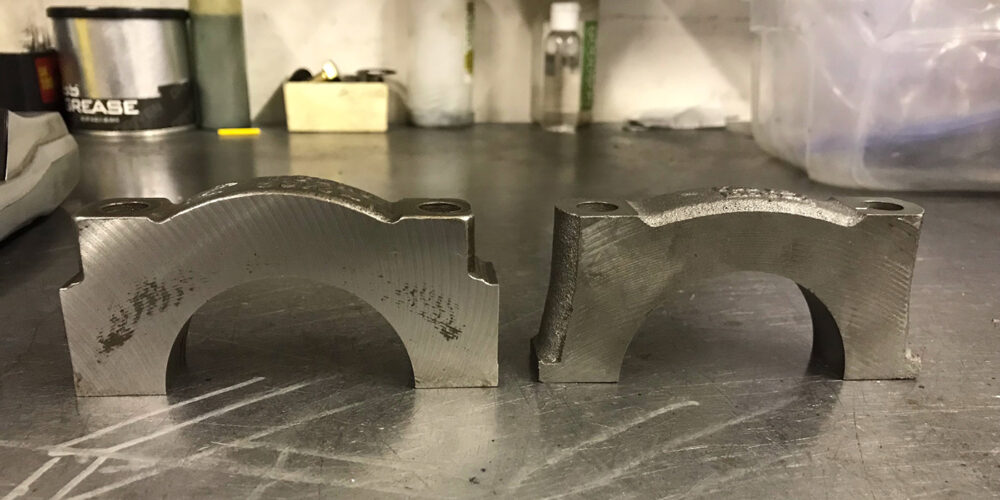

Heavy-Duty Front Cap

For some extra strength on the front main bearing on several different engine platforms, you can narrow up a beefier 4-bolt cap to fit the 2-bolt register. If the radial depth is close enough to be able to “hone-in,” you often don’t even need to rough bore them. Here’s an example of a nodular 4-bolt Chevy cap, modified for the front main. It’s around 50 grams heavier and the material is almost three times as strong as the stock cap. This is great for rule legal applications where factory caps must be used.

Ron Flood

Cedar Machine

North Branch, MN

How Big is Your Warranty?

“90-DAY WARRANTY”… “1-YEAR WARRANTY”… “LIMITED LIFETIME WARRANTY”… Many shop owners hand write the coverage on the customer’s invoice. But what does it cover? Does this protect your shop? A written warranty provides benefits for you and your customer. It sets expectations, protects both parties and is a great marketing tool that encourages repeat business.

Many warranty claims are a result of customer neglect. We see rebuilt engines or heads put in a vehicle without checking the other systems, mainly cooling system and ignition system. And, maintenance schedules are often overlooked by the vehicle owner, particularly during the important break-in period. A written warranty needs to include what is covered and for how long, and it needs to outline the customer’s responsibilities.

Warranty templates can be found online, and you can get good advice from industry and business associations, and it’s a good idea to seek legal help when establishing a company warranty policy. In addition, it’s a good idea to protect your investment by attaching heat tabs to heads and blocks and to let your customers know what they are and where they are located; warranty void if removed! A written warranty will give your customer confidence in your work and can save you money and aggravation by establishing customer responsibility up front.

Steve Rich

Don Gross Warehouse – Sterling Engine Parts

N Kansas City, MO

Nick Jones

Automotive Machine

Fraser, MI 48026