Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

Diamonds Aren’t Always Forever

When using my profilometer for bore and surface readings, I hold the drive on the workpiece until the stylus has retracted and recorded it’s reading. Then, I lift it off and let it retract without touching the workpiece. This effectively reduces the amount of contact time that the stylus sees by 50%. Your reader will stay in calibration for much longer, and the stylus diamond will have a longer life. I’ve never had a problem holding it in bores or on surfaces, because I have the drive body face covered in paint protectant film. It gives it some traction.

Ron Flood

Cedar Machine

North Branch, MN

T-Taps

I have some pipe taps with a T-handle welded on we keep in the cleaning department. It’s easy to clean the rust or sealer from oil galleys and block drains. You cannot make the holes deeper with these, and they don’t walk away with the T-handle on them.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

A Simple Reminder

Even well-regarded, brand-name dial indicators typically have a +/- accuracy equal to 1x to 2x their resolution and can read +/- 0.0005″ after 2 to 3+ revolutions. For example, a Mitutoyo 0.5″ range, 0.0001″ resolution indicator has a factory stated accuracy of +/- 0.0002″, and a first revolution error of +/- 0.0002″. This +/- error increases with each additional revolution to as much as +/-0.0005. Almost all dial indicators are most accurate during their first half revolution. Good stuff to know when using an indicator.

Eric and Tom Nichols

AMS – Moto Machine & Supply

Cleburne, TX

Coat-It Hanger

If you coat head gaskets with copper coat spray, using a clothes hanger as a support is a convenient way to keep the spray off of your hands and to keep your gasket from sticking to another surface.

Adam Cofer

Don Ott Racing Engines

York Springs, PA

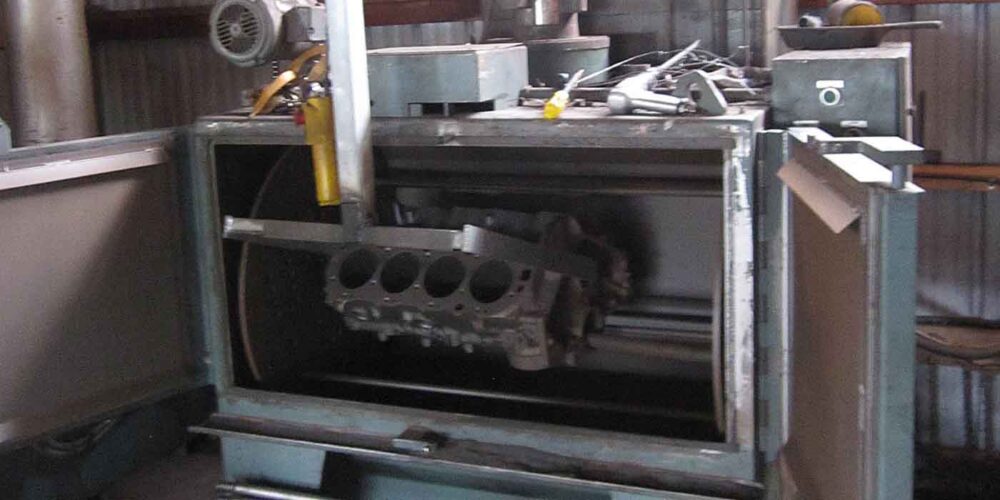

Load Blocks with Ease

I have an older thermal cleaning system by Peterson. The shot blaster is designed more for cylinder heads than blocks as it is a side loading machine. To wrestle blocks into the machine was not reasonable so I came up with this simple solution to the problem. Maybe everyone else has already done something similar, but if you haven’t and would like to place blocks into your machine it is a good way to do it safely. It’s “C” shape allows you to load cylinder blocks well into the machine without a struggle.

Bob Cull

Cull Enterprises Ltd.

Creston, B.C.

LS Piston Pin Size

Stock GM LS full floating connecting rods use a .943” pin and stock LS press rods use a .945” pin. Some aftermarket forged pistons designed to use a stock LS 6.098” length rod come with the .945” pin type. Pistons can be used as “Pressed” or “Floating” and are supplied with lock ring grooves and locks for .943” rods that must be honed for floating pin clearance. This way, one piston can be used for either connecting rod type.

Many, if not most aftermarket forged LS pistons come with a .927” small pin, like those used in small block Chevys. They also have a shorter compression height to accommodate an aftermarket 6.125” long connecting rod.

Care must be used when shopping aftermarket pistons to match the correct connecting rod pin size and length.

Engine Pro Tech Committee

Special thanks to UEM / Icon