Engine and Machine Shop Tips and Tricks

EFFICIENCY BY THE YARD

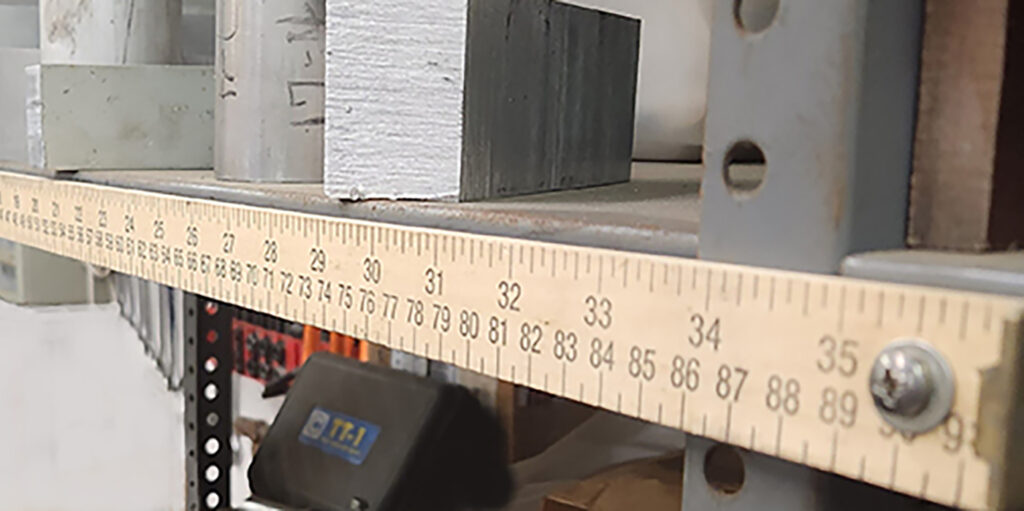

Attach a yard stick or length of an old measuring tape to the front of shelves where there’s often a need to check the approximate size or length of inventory items to increases shop efficiency. It saves a lot of time and steps going back to the toolbox for a tape measure, calipers, etc. Also helps when stocking and sorting bulk inventory. We’ve found it prevents inventory from being carried away to be measure and then left sitting somewhere in the shop if not the size needed, despite the best intentions to return the item to the shelf. This is good for getting a rough measurement for cylinder sleeve lengths, frost plugs, stud & bolt length, belt length, metal billet sizes and more. It’s surprisingly more useful than one might expect.

Tom Nichols

Automotive Machine & Supply, Inc

Joshua, TX

UNDER PRESSURE

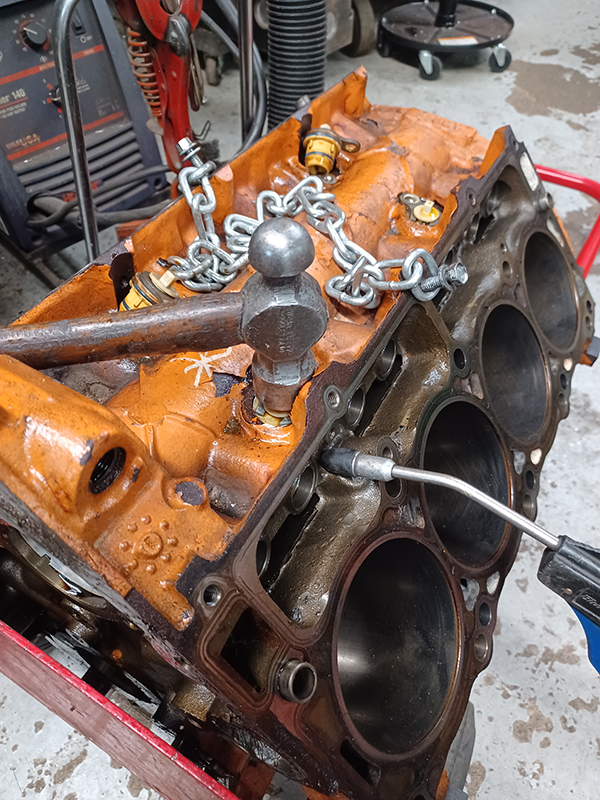

3rd Gen Hemi MDS plugs can be tricky to remove. Even more so to get them out without breaking them! Here’s a simple trick. Spray some penetrating oil around all the plugs, then apply compressed air with a rubber tipped air blower to the MDS drain port located in the middle of each lifter bank. While holding air pressure to the port use your other hand to lightly tap on the top of the plug with a small hammer. As you tap on the plug with air pressure on it, it’ll work up and down and eventually pop right out! Sometimes they really come hustling out, so be careful and wear your safety glasses.

Jake Sampson

Sampson Racing Engines

Inver Grove Heights, MN

JUST IN CASE YOU MISS

Everyone misses occasionally, and this helps avoid dents and damage. When I need to adjust the guides to the correct depth after getting close with the air hammer it’s good to protect the head. Everyone misses sooner or later, and this simple board will save you and avert egg on the face.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

DRAG MARKS

When resurfacing aluminum heads where the seat insert is contacted, sometimes the tool bit can leave tracking or drag marks across the deck surface in that area. To avoid this, you may be able to simply chamfer the seat slightly before the finish cut, so the tool bit doesn’t contact it. Experimenting with different lube can help as well.

Ron Flood

Cedar Machine

North Branch, MN

APPLY PRESSURE HERE

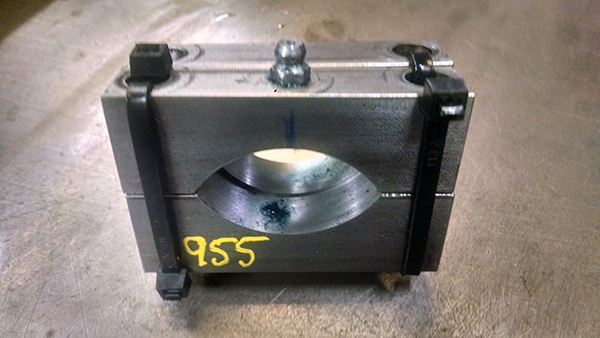

I found myself without a welder to use to remove a check ball staked into the end of an oil passage of a crankshaft. So, I applied a different technique to remove it to clean the crank. I clamped some piece of steel together to form some “Caps”. I had to place some spacers between them to leave me enough material at the tops of the radius. I drilled them on end and then bolted them together like you might 2 rod caps, still with spacers in the middle. Then I bored the centers on my mill. One machined to the diameter of the rod journal and the other the main journal. The one for the main was drilled and tapped for a Zerk-fitting, which you can see in the photo. Before clamping the caps to the crank, I ground away the staking around the ball. Then I clamped the small diameter caps to the rod journal around the oil hole. From the main journal side, I dripped some oil in the hole to displace some air. Then I clamped the main journal diameter caps around the oil hole in the main lining the Zerk up with the hole. Using pressure from a grease gun the ball came out of the end of the journal throw with ease. I believe these caps will work again as well if the crank has smaller journals.

Steve Morton

R & R Machine Company

Warwick, RI

RECONDITIONING DIESEL CONNECTING RODS

The goal when servicing diesel connecting rods is to ensure the full set of rods are straight, on size and of the correct length. They should be machined back to the original OEM specification. Honeable bushings are acceptable if no other connecting rod big end machining has been performed and is recommended to only hone the bushing inside diameter. Boreable bushings are required if modification has been performed on the connecting rod big end. Since the rod center-to-center length has been modified, this measurement must be re-established for the full set of rods. Maintaining the rod center-to-center length is key to keep compression ratio and cylinder combustions temperatures uniform. The final step in either bushing use should be to install the piston pin and check the alignment of the piston pin to big end of the connecting rod. Assembly of the connecting rod and piston in the cylinder block assembly will then give you the protrusion/recession specifications to compare with the OEM specifications.

Engine Pro Technical Committee with special thanks to MaxiForce Diesel Engine Parts