Over the years, we’ve gotten asked numerous times about connecting rod length and the impact that has on an engine’s horsepower and durability. As it turns out, this question is often overthought. It’s not so much the connecting rod length that matters as much as it is the correct piston pin height. The connecting rod length factors into the whole equation, but it isn’t the basis for what will give your engine more horsepower or better durability.

We chatted with engine builder Steve Morris of Steve Morris Engines to get his take on connecting rod selection, and whether rod length is more important than other factors within the rotating assembly setup.

“My short answer is, there’s a whole lot of overthinking on the connecting rod length and horsepower versus all this other stuff,” Morris admits. “In the boosted world, our main goal is making the engine live. It’s not hunting for 10 extra horsepower because we have the perfect rod-to-stroke ratio. In the NA world, you might be hunting for 10 horsepower and they can alter deck heights, they can alter connecting rod lengths to the crankshaft and can get away with different piston pin heights. That’s a good possibility.

“However, I’d stake money on somebody testing back-to-back different rod lengths and it not making a difference. Unless you’re talking about a 1” difference in rod length or something really, really dramatic, which would take a totally different engine platform, so everything changes – an inch-taller deck height block and an inch-longer rod – that lengthens out the intake manifold and the intake runners. It changes the characteristics of everything, so you’d never get a true, accurate look at that whole entire package.”

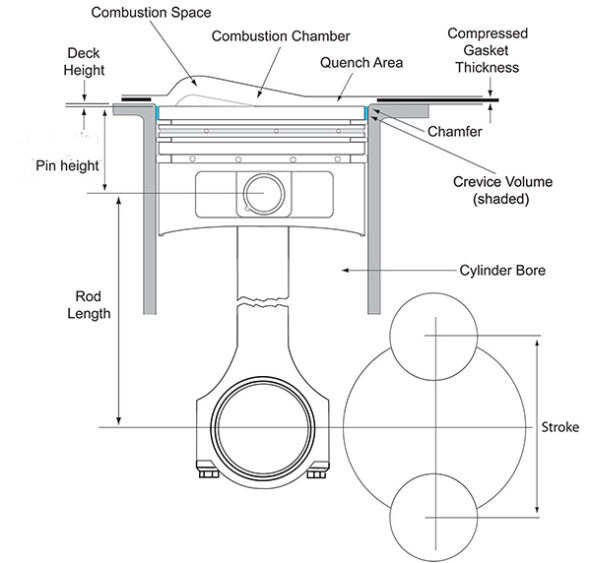

According to the folks at Diamond Pistons, many racing engines use longer connecting rods to help reduce piston weight while having positive effects on torque curve shape and positioning and combustion efficiency. Longer rods typically require shorter, lighter pistons. This pushes the ring pack higher on the piston. In normally aspirated applications, builders appreciate this because they like to move the ring pack up to lighten the reciprocating assembly, improve piston stability and minimize unburned gasses in the crevice volume above the top ring.

However, longer rods in a boosted application can be problematic because the ring pack needs to be further down the piston to move it farther from excessive heat. Longer rods make this difficult to accomplish as the pin bore intersects the oil ring groove. In many cases a shorter rod can be specified for boosted applications because boost pressure reduces the need for the critical rod/stroke tuning relationships required for efficient normally aspirated operation.

Ultimately, the correct piston pin height is what you’re trying to achieve. In speaking with Steve, he’s selecting components and making calculations that get him the piston pin height he desires, most importantly.

Once rod length is chosen, you have two parts of the equation. Since the rod length and stroke are now fixed, the pin height is the remaining variable. To find the necessary pin height, add the rod length and half of the stroke and subtract the result from the block deck height. Blocks that have not been decked typically provide a fudge factor of about .020”. This is often removed when the block is zero decked to match the piston crown. At this point, the builder can evaluate the available room for the ring pack and determine whether a longer rod negatively impacts ring location.

“I look at the connecting rod choice based on where my piston is going to be,” Morris says. “I can’t have too short a piston pin height. If I have too short a piston pin height in a high-horsepower application, the pistons will be weak and could break. A lot of times that dictates what length rod I put in will be shorter because I need to have a correct piston pin height.

“I look at it from the standpoint of the entire package. If people want to overthink it and over-engineer something and try to figure out the perfect connecting rod-to-stroke ratio, but it’s got a wrong piston pin height in it and makes the piston weak and the piston breaks, well, who cares? Who cares how great it is if it breaks?

“I don’t hunt for any mythical, magical rod-to-stroke ratio. I do what makes the combination correct and how I can keep a piston alive in it, and how I can keep the rod alive in it. That all depends on the deck height of the block, the stroke of the crankshaft and all of those things factor in. I don’t think about rod-to-stroke ratio.”

If piston pin height is what builders like Steve Morris are after, what piston pin height does Steve generally look to achieve? Depending on the bore size, Steve likes to be in the range of 1.250” to 1.350”.

“The 1.250” to 1.350” is a typical big block-type pin height package,” Morris says. “With LS stuff, we try to be in the 1.200” range. If I could, I’d still like to have everything be down in that 1.250” to 1.350” range if possible. With small cubic inch and short deck motors, you just can’t get it into that range very well.”

Generally speaking, Steve told us he often opts for a shorter rod due to the engine combinations he so often builds.

“In our combinations, I don’t do anything with extreme tall deck heights, so you can’t physically put great, big, long rods in if you don’t have really tall deck blocks,” he says. “We don’t ever use any of that stuff, and we don’t do any really huge cubic inch stuff (900 cid). The longest rod that I have is a 6.800”. I prefer short connecting rods because of angularity and how it crosses top dead center in an unlimited, boosted application.”

Obviously, different engine platforms, such as Chevy, Ford and Hemi, utilize different length connecting rods, but one of the other issues builders run into with connecting rod length is with the various crankshaft counterweights.

“In an LS package, all the crankshafts are counterweighted for a 6.125” to 6.200” long rod,” Morris points out. “If I wanted to put a 6.000” long rod in an LS with a 4.000” stroke, you end up having to cut the counterweights down and have to do a bunch of balancing to make that all work because it pulls the piston and piston pin down into the counterweights, because it’s designed for a longer rod.

“If at all possible, I like to use the 6.125” rod in an LS. Sometimes we’ll use a 6.000” rod in LS stuff depending on what the stroke is. But, we do sometimes have to cut counterweights in order to put a 6.000” rod in an LS package.

“In big block Chevrolet stuff and my SMX combos, my common connecting rod is a 6.385” all the way up to a 6.800” rod. With Hemi combos, it depends on the deck height and the stroke, but the common rod lengths are 7.100” to 7.300”. I think 7.100” is the longest I like to use and down to the 6.800”-6.600” range.”

According to Steve, these small changes in connecting rod length don’t affect horsepower levels, but they can have an affect on durability.

“If you take a 540 cubic inch big block Chevrolet boosted engine with 3,000 horsepower, typically, that’s going to have a 6.385” long rod in it,” he says. “If I put a 6.250” long rod in it, it’ll make zero horsepower difference that I can detect. If anything, it might even make it a little bit better in piston pin height and make a stronger piston. But, it would require a bunch of balancing and a bunch of counterweight crankshaft changes to make it work.

“If you put a 6.535” rod in it, so .150” longer, it’ll make zero horsepower difference, zero longevity difference, with the exception of it moving the piston pin up into the piston, which makes the piston weak and prone to break the piston.”

Again, engine builders should be looking for the solutions that provide these engine components with the best opportunity to live and live well within the environments a particular engine will be used. For those reasons, Steve says, “Go with as long a connecting rod as you can that makes the rest of the math all figure out correctly and still makes a good piston. That’s the primary thing. If you know what stroke you’re going to have and what deck height you’re going to have, put the longest rod you can in there without sacrificing piston durability.” EB