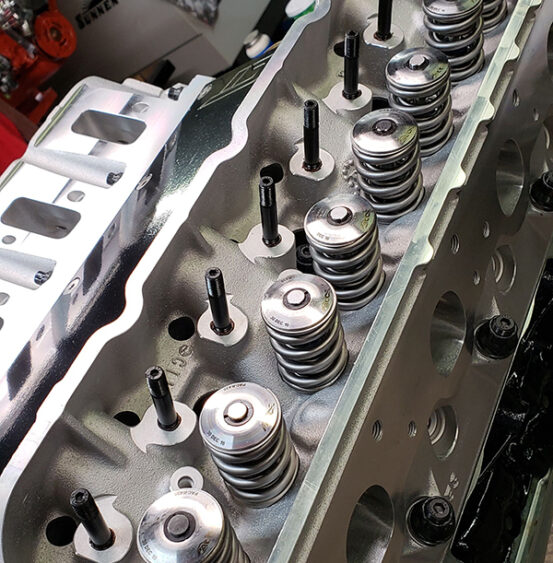

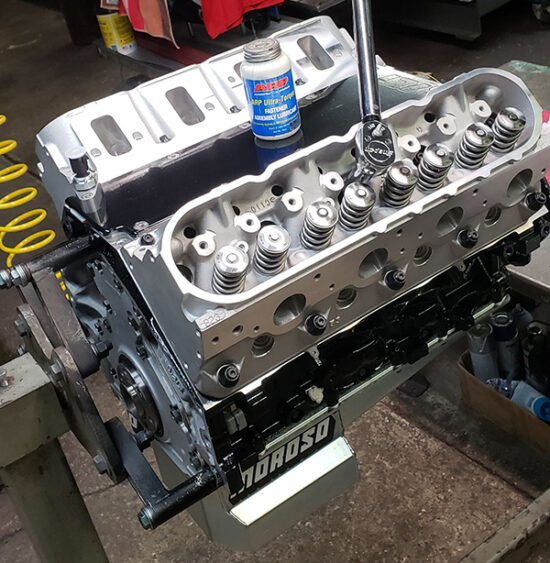

If you want to properly control the movement of your engine’s intake and exhaust valves, you’re going to need valve springs. Precise control over valve timing and lift is essential for optimizing engine compression and overall performance, and in high-performance engines, valves open and close at very fast speeds. For that reason, valve springs also play a significant role in maintaining stability within the valvetrain. They counteract the forces generated by the camshaft, pushrods and rocker arms, ensuring the valves follow the camshaft’s profile accurately.

If the valve spring is not strong enough, it may not close the valve quickly enough, leading to valve float. When flying down the track at breakneck speeds, reduced power, engine misfires and even engine damage are the enemy of racers and engine builders alike.

High-frequency fatigue, also known as harmonics, are a ubiquitous challenge in racing engines and can potentially wreak havoc on the valvetrain if left unchecked. Well-designed valve springs play a pivotal role in managing this, ensuring essential stability, and minimizing wear on valvetrain components.

Different camshaft profiles require specific valve springs to function optimally. Performance engine builders carefully select valve springs to match the camshaft’s lift, duration and other characteristics, ensuring efficient power delivery.

Over the past 25 years, however, valve spring technology has undergone a revolution in materials, processing and configuration, allowing for manufacturers to redesign cams and valvetrains to rev higher and make more horsepower – but mainly to be more reliable. While there are big-name valve spring manufacturers that have been catering to high-level racers and builders for years, the growth of the drag-and-drive scene and street-strip market have encouraged manufactures to target the “middle level” engine classes as well.

Melling is one of those manufacturers, offering a number performance valve spring lines for both gas and diesel engines. Since acquiring Performance Valve Springs UK Ltd. in early 2020, they’ve expanded their offerings, and even built a 5,000 sq.-ft. addition to add storage, raw material space, and aid in manufacturing.

“We’ve got a really good offering of LS stuff since that’s kind of where the market’s at right now,” says Cale Risinger, performance & aftermarket product manager at Melling. “There’s Godzilla and Hemi springs now and we’ve always had a good selection of the old small block stuff and old muscle car era engines. We don’t have springs for the higher-end NASCAR and drag level stuff, but we can work up to very good street strip and circle track stuff.”

Risinger explained that there are a few key metrics to look at when it comes to performance valve springs and selecting what’s right for your build:

Spring Rate (lb/in): Spring rate refers to the force required to compress the spring by one inch. It’s a fundamental parameter in understanding a spring’s stiffness. In high-performance applications, selecting the appropriate spring rate is critical to match the camshaft’s profile and engine requirements.

Installed Height (in): This measurement represents the spring’s length when it’s installed in the engine at its specified seat pressure. It’s essential to ensure the installed height matches the engine’s design to maintain proper valve timing and avoid valve float.

Seat Pressure (lbs): Seat pressure is the force exerted by the valve spring when the valve is fully closed. Achieving the correct seat pressure is vital to prevent valve bounce and maintain valve control at low rpm. In boosted applications, greater seat pressure is a must.

“The first thing we have to look at is obviously the cam,” Risinger notes. “What are we dealing with as far as the cam goes? What about lift? If we know something about the load profile, we can look at that too.”

There are a few different configurations for valve springs, but Risinger says that Melling often recommends a beehive spring design. Beehive springs offer advanced engineering and come with smaller diameter coils that help to enhance spring performance under higher rpm situations. Unlike other kinds of springs, it can control float more easily.

Beehive springs are naturally lighter than other options, which make them a toss-up as you continue to gain power. A lot of builders still refuse to go with a single spring and opt for dual springs or even triples, which add a layer of protection to keep the valve closed in the event of failure. These work great for engines with heavier valvetrains.

Conical springs are also an option for builders. What distinguishes a conical spring from cylindrical or beehive springs is its harmonic stability. In situations where enhanced stability is required, dual cylindrical valve springs are often resorted to. However, they come with certain drawbacks, such as increased weight and heightened valvetrain wear due to the interference fit between the inner and outer spring.

Conical springs present a favorable alternative to costly dual spring setups, although they also have inherent design limitations. These springs feature coils with varying diameters and a progressive rate, which results in a self-damping effect. When one coil reaches its harmonic frequency, the adjacent coils work to dampen the resonance, significantly reducing spring oscillations at high rpm.

“We dip our toes in both the beehive and single/dual springs – some of our biggest sellers are still those entry level, small block Chevy springs, which are a single spring and a damper,” Risinger says. “But the dual LS springs are really hot too. I think LS, LT and Godzilla engines will continue to be big markets for the next few years.

Professional engine builders understand that achieving peak performance requires meticulous attention to every component, including valve springs. By analyzing critical metrics such as spring rate, installed height, seat pressure, open pressure, and valve lift, engine builders can select the perfect valve springs to match their camshaft profiles and engine applications.

Be mindful that valve springs are not a one-size-fits-all component. They are another precision component that allow engines to reach their full potential. Whether you’re building a high-revving, naturally aspirated powerhouse or a boosted beast, remember that the right valve springs are your key to unlocking the engine’s true power. Consult a valve spring manufacturer to understand the latest innovations and what valve springs will work for you. EB