When it comes to the Chrysler Hemi-based engines used in Top Fuel dragsters and Funny Cars, you’ve likely heard the commonly referred to 11,000 horsepower those engines can make. That’s 1,375 horsepower per cylinder! That level of performance is pretty insane, but did you also know these drag cars are knocking on the door of 340 mph, and are getting very close to 300 mph in the eighth mile? Or how about the fact that they burn roughly 15 gallons of fuel in a single run, and at maximum pull down around 6,800 rpm, they flow 90 gpm of fuel?! These engines also create so much horsepower that many engine components are only good for one to five runs, and in the case of pistons, the amount of force can even reduce the dome to some degree!

It’s the pinnacle of drag racing, and the engine builders, crew chiefs and teams who make these cars function at peak performance all season long are looking at every single area of the engine and the car to make it down the track as fast as possible. We wanted to highlight some of the features of the 426 Hemi-based engines used in Top Fuel and Funny Car, as well as what truly goes into each run and the thought process of an NHRA team.

To do that, we spoke with NHRA driver Joe Morrison and NHRA crew chief Rob Flynn about their experiences in both Top Fuel and Funny Car classes.

Hemi-Based Engines

As mentioned, the engine used in Top Fuel and Funny Car is loosely based on the 426 Hemi. The NHRA rules dictate that it can be no more than 500 cubic inches, and camshafts can only be as big as 54mm, but aside from that, teams can generally build the engine how they want and use whatever components they want.

“It’s all based off the Hemi,” says Rob Flynn, an NHRA crew chief with a background in both Top Fuel and Funny Car classes since 1994. “The blocks are all billet aluminum and the heads are billet aluminum also. There’s no water passages in any of that stuff. The bore and stroke is a constant and that’s a 4.500” stroke and a 4.187” bore. That’s basically what the NHRA rules allow. There were some people who were into a little bit shorter stroke and a bigger bore because the stock Hemi bore size is 4.252”. When all of us ended up making our engines bigger, they limited the cubic inch to 500 cid, so the engines are around 496 cid for both classes.”

Since these engines are loosely based on the Hemi, they differ in a couple ways from a stock 426 Hemi, according to driver Joe Morrison.

“I say loosely based because there have been many modifications made to increase the airflow of the intake and exhaust ports,” says Joe Morrison, a Funny Car driver for Herzhauser Racing and a former Top Fuel driver for Leverich Racing. “Also, the major difference from a stock 426 Chrysler Hemi would be that we have two spark plugs per cylinder as opposed to just one. That is for two reasons. Number one, methane is explosive when compressed, but not super flammable, so it takes more to get it to light. The second reason is that we burn an enormous volume of fuel.”

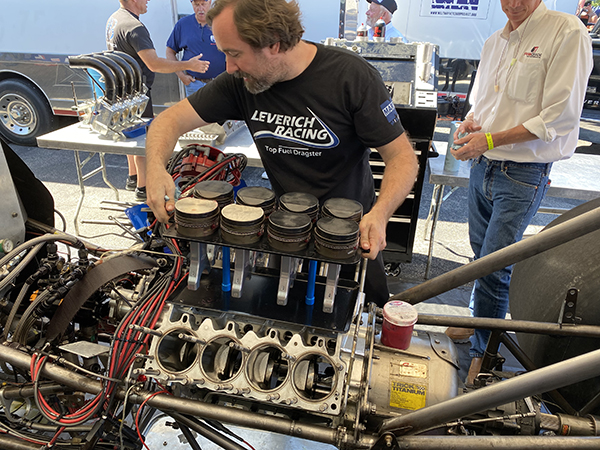

We’ll get more into fuel in a moment, but for internal engine components, the NHRA doesn’t dictate what teams are allowed to use, however, apart from different brand names, the components are generally similar. Teams run aluminum connecting rods, forged aluminum pistons and different compression ratios and different ring packages.

“Teams can do what they want when it comes to internal components,” Morrison says. “You can vary your connecting rod length and your compression height of the pistons. Typically, because of the intense heat, the ring package is further down on the piston.”

According to Flynn, a Dykes top ring was commonly used in the past and the second ring was also a compression ring, and some people used it as a scraper, but predominantly now, most people use a compression ring with gas-ported pistons.

“We use the same compression ring in the first and second groove and then we have an oil ring, and the oil ring takes a lot of abuse, so we make one run on that and throw it away,” Flynn says. “A tremendous amount of parts get cycled through these engines. The engine comes apart every run, so everything either gets replaced or reconditioned. In our situation, we’ll take the top ring and put it in the second groove and install a new top ring and then we’ll replace the oil ring.

“With the bearings, the upper rod bearing takes a lot of load on it and we actually measure that each run. That usually gets replaced every run because there’s quite a bit of clearance to begin with and you don’t really need any more. The main bearings, predominantly the lower half, get replaced or certainly inspected every run.

“The valvetrain components have a certain amount of runs they’re typically good for, such as camshafts and lifters. Everything gets inspected every run due to the kind of power we’re making. It puts a lot of stress on the internal components.

“After every run, we measure the bearings, the pistons, how much the pistons sink, how much the bearing squashes, if the rings have too much heat and lose tension. The piston can knock the ring land down. Each run, the pistons get a little bit of sink in the dome and the center of the dome, so we measure that and there’s a certain number where we deem that piston not satisfactory anymore. That could be one to five runs.”

As mentioned, the camshaft in these engines can’t be larger than 54mm, but it is in the standard position with pushrods and overhead valves and two valves per cylinder. Something many teams do is change the camshaft firing order to garner better harmonics.

“Instead of a stock Hemi firing order, we’re using the Chevy LS firing order,” Morrison says. “We’re firing the outside cylinders first and then the inside cylinders.”

Flynn elaborates by saying the standard firing order is similar to a small block Chevy, but the majority of the class runs what’s called a 4-7 swap firing order, but some use an LS firing order, which is a 4-7, 2-3 swap.

“It’s a preference thing,” Flynn admits. “I don’t know that either one makes any more power, but there’s some discussion that the engine runs a little smoother with certain swaps. One thing I’ve noticed on the LS swap is the cam is a little structurally stronger. However, I don’t think either one of those makes a huge difference in performance. It’s just a personal preference that people have.”

These Hemi engines also feature a Roots-style 18-71 supercharger, which typically sees 50-60-lbs. of boost and can dictate a lot when it comes to these engines’ compression ratios.

“The compression ratio on most teams would be 6.5:1 to 6.8:1, and that varies on the atmospheric conditions,” Flynn points out. “On a cool, dry day in Florida, you’re going to run 6.5:1, and then on a hot, humid day in Topeka, KS you’re probably going to be in the 6.7:1 or 6.8:1 range. There’s some people who have different setups that might be lower or might be higher than that.”

Final compression ratio is based on barometric pressure, and that adjustment is made once you have your compression heights and your combustion chamber cc’d, but that final compression ratio decision is also based on your head gasket thickness, which for these classes is typically between .070”-.080” and up to .120”.

As for oil, these engines run nitro 70, and the reason being is to help fight blowby. The nitro dilutes the oil because of all that cylinder pressure and that volume of fuel. The heavier engine oil acts like a cushion.

“When we fire the motor up when it’s cold, we’ll see up to 300 psi of oil pressure,” Morrison says. “As I’m staging the car after the burnout, after the engine is heated up a bit, we’d love to see 120 psi.”

Fuel

To make the horsepower levels that Top Fuel and Funny Car do, it’s no secret that a lot of fuel is needed. From starting the car to doing the burnout and backing up, making crew chief adjustments, making the run to shutting the car off, a Top Fuel or Funny Car will go through in the neighborhood of 15 gallons of fuel.

“The fuel line is about 3” thick, and the fuel pumps flow somewhere in the neighborhood of 100 gpm,” Morrison says. “We’re idling between 3.6-3.8 gpm. It’s burning a lot of fuel.”

Regardless if you’re in Top Fuel or in Funny Car, you are only allowed to run 90% nitromethane fuel. This percentage varies from crew chief to crew chief, but most teams are running between 88%-90% nitro. To help deliver mass amounts of fuel to the engine, these combinations have numerous injectors located in several different areas of the engine.

“There’s six nozzles right in the front of the blower, and then there’s another four in back of the blower to keep that all lubricated,” Flynn points out. “In the manifold, most teams would have one nozzle, but some have two. Then, we have two in the intake port also. Usually, you idle off of what’s coming through the blower and then some people have one of their idle nozzles in the manifold and then some people have one of their idle nozzles in the intake port itself. It’s just a personal preference. I would say more Funny Cars than dragsters idle in the manifold, but it can go either way.”

Tuning

Due to the fact that these engines are all very similar, much of the difference in performance from one team to another comes down to tuning. In Top Fuel and Funny Car classes, you’re often tuning cylinder by cylinder versus the entire engine at once.

“We try to balance very, very closely each particular cylinder,” Morrison says. “We’re not really tuning an eight-cylinder engine, we’re tuning eight one-cylinder engines.”

Again, you’re finding out the atmospheric conditions of the day and then you make your compression ratio calculations. Teams also have software that helps make these decisions, but your tune is related to air and somewhat to track conditions.

“You’re making these adjustments all the time,” Flynn notes. “You go up to the staging area and you’ve got a basic setup and if the weather changes you can make some timing adjustments or fuel adjustments or overdrive adjustments up until maybe three pairs ahead of you. At the same time, you’re following the track conditions and you’re making those adjustments too depending on whether the track is cooling off or heating up. You’re making those adjustments up until the last second so you can make a successful run.

“On a super-hot racetrack, you’re not trying to make the maximum amount of power because you can’t hook it up anyway. On a really, really good racetrack, you’ve got to make it as far as you can because the tire’s stuck pretty good. The Funny Cars are a little bit more touchy on a hot racetrack than a dragster because of the short wheelbase, but at the same token, they apply their clutch in a lot slower and smoother manner than a dragster does.”

One of the factors that force teams to tune these engines cylinder by cylinder is something Flynn calls compression balancing. There’s certain cylinders, no matter how much fuel you give them or take away, they’re just not happy, so you have to change the compression ratio.

“For us, we have three different pistons in the engine and some teams might even have more than that,” Flynn says. “Because of the flow through the blower, it picks on certain cylinders and so you can only put so much fuel in there and you have to take some of the pressure away from it. That’s compression ratio.

“In the past, there’s been situations where you divert the air a little bit in the manifold. You could maybe do that also with rocker arm ratios. We definitely tune each engine trying to make the same amount of power with each cylinder. We’re able to change the fuel curve through nozzles in the manifold, nozzles directly in the intake port and then there’s air and fuel coming through the blower. You’ve got all these areas where you can make adjustments on an individual cylinder basis.

“This year, they’ve given us the ability to change the individual timing cylinder to cylinder too. We haven’t had that before. Maybe this timing thing will help us fine tune those cylinders that are a little bit of a problem.”

Differences in Top Fuel & Funny Car

While the engines in Top Fuel dragsters and Funny Cars are fairly similar class to class, there are some bigger differences between the two outside of the obvious chassis length and body shape. For instance, there are speed and ET differences.

“You can be more aggressive with the launch of a Top Fuel car, and that’s really because of physics,” Morrison says. “You have a longer lever. You can be more aggressive early with regard to power, clutch engagement and that sort of thing. The Top Fuel cars have a bit more down force with the front and rear wings.

“Funny Cars are relying on the aerodynamics of the body as well as the down force from your headers. The dragster, when driving it, your steering input is really more delicate when controlling the car. With a Funny Car, you have to be a bit more aggressive and they tend to want to move around more, so you’re busier trying to keep it in the groove.”

The difference in ETs between the dragsters and Funny Cars is a mere couple of tenths usually. That difference is due to the cars themselves. The dragster is more aerodynamic, has less wind resistance and they have more down force. At 300-plus mph that makes a big difference.

“Being that it’s a longer lever, that ability to launch the car more aggressively and have it stick to the track better is really why they perform a little better,” he says. “The fastest Top Fuel times are in the 3.60s versus the fastest Funny Car times being in the 3.80s.”

Believe it or not, the NHRA has an ignition limiter on these cars, so when they get over 8,000 rpm it starts to take some timing out past a certain point.

“We’re allowed to put our own timing curves in, but the last point that we’re allowed to have any kind of advance is at 2.7 seconds,” Flynn says. “Everything has to be done at 2.7 into the run, which basically would be 400-500 feet into the run. From a dragster standpoint, from the eighth mile on, we’re in a situation where the timing is retarding because we’re capped at 8,000 rpm where it starts taking away. The engine will still go to 8,300 rpm when it gets to the finish line.

“These days, they take away something like 25 degrees of timing, maximum, in a second. It’s taking out quite a bit of timing. If you’ve got 58 degrees or something as your last number, by the time you get to the finish line, it’d be close to 48 degrees or less.”

As far as performance, some teams are knocking on the door of 340 mph in the quarter and 300 mph in the eighth.

“There’s a few cars knocking on the door there, and it’s pretty common for us to be running 294-295 mph, but there are some cars that have touched into the 299 mph range [in the eighth],” Flynn says. “In fact, one of the companies has put up a little bonus for the first one to do it. Additionally, there’s a club for the 300 mph at the eighth mile, so we’re all shooting for that, but there’s certain cars that have a better chance of it than others.”

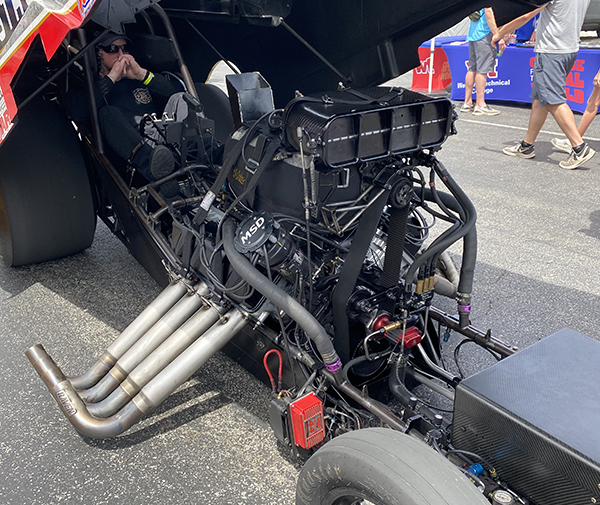

One thing helping the cars’ performance on the track, which many people may not realize, is the zoomie-style headers themselves.

“Zoomie-style headers are individual pipes out of each cylinder,” Morrison explains. “The angle at which those headers are, on the Funny Cars in particular, we use what’s called a laid-back-style header, and what’s important about that is it’s a balance between creating down force as well as thrust. It’s more effective with Funny Cars, and not so much with the dragsters because the rear tire is right there.

“Those headers on the dragster as well as the Funny Car do provide a pretty significant amount of down force helping to keep the car on the ground. It’s something that’s overlooked often by the casual fan. Even a seasoned engine builder may or may not be thinking about that. The power that’s being released from the nitromethane making 11,000 horsepower – that’s a ton of thrust. We use every bit of it to our advantage.”

Making 11,000-HP Live

Ultimately, the car and engine combo needs to survive long enough to make a successful run, otherwise your team won’t be advancing round to round during NHRA weekends. According to Flynn, the biggest differentiator is the people bolting the cars and engines together.

“A lot of major catastrophes happen when there’s failures, and sometimes that’s a mistake,” Flynn notes. “Tuning-wise, you can push the parts too far past their limit. Some of the components have a run limit and you have to take it out before it fails. You have to maintain all of that. Everything is taking a huge beating.

“If you take the commonly referred to 11,000 horsepower and divide that by eight cylinders, that’s a lot of horsepower out of 62 cubic inches, which is each cylinder. You’re making over 1,300 horsepower out of each of those cylinders. That puts a lot of load on all those components. A lot of it is just maintenance and everyone bolting it together doing things right and inspecting your parts after a run. When it looks like something is not very happy, it probably isn’t. The biggest thing is balancing air, fuel and the compression ratio to make the engine happy.

“A lot of times you can run it hard enough to blow up, but with the cost of components, you certainly don’t want to have that happen too often.” EB