When sportsman drag racer Dean Dubbin couldn’t find protective awnings that met his race team’s needs, he created his own. Similarly, when he needed engines for his Top Alcohol dragster, he turned to a source he could trust – himself.

Now, Dubbin, from Little Falls, MN builds race/hospitality and display trailer awnings for some of racing’s most successful teams (with DMP Awnings) and engines for several competitive sportsman racers.

“Typically, this time of year, we’ll start out with at least three complete motors and one extra set of cylinder heads in the trailer,” Dubbin says. “We have the extra set of heads because a lot of times you’ll burn a head gasket or drop a valve or something. Well, we can just change the liner, rod, piston on one side and we’ll be back ready to go.”

According to the National Hot Rod Association (NHRA) the Top Alcohol classes consist of Dragster and Funny Car racers. Visually almost identical to their professional Top Fuel counterparts, the alcohol cars have some major differences.

Top Fuelers use supercharged engines that burn a mixture of 90 percent nitromethane and 10 percent methanol. Top Alcohol Dragsters may be powered by one of two different powerplants, either a supercharged methanol-burning engine or an injected nitromethane combination. It’s kind of strange, Dubbin says, that both types of engines can run side by side in Top Alcohol, but he admits that it’s a pretty level playing field. “Our supercharged engines are 471 cid where the nitro engines are 331 cid, but they both make around 4,000 hp.”

Weights vary according to combination but are generally between 1,975 and 2,125 pounds. Like Top Fuelers, Top Alcohol Dragsters are restricted to a maximum wheelbase of 300 inches.

Top Alcohol Funny Cars also look nearly identical to the Top Fuel counterparts, but are restricted to the use of methanol fuel and have a three-speed transmission. The less volatile fuel means Top Alcohol Funny Car bodies do not need as much downforce and use a much smaller rear spoiler, though they remain pure race cars with the same chromoly steel chassis and carbon-fiber replica bodies.

Top speeds for Top Fuel cars have climbed well into the 330 mph range where Top Alcohol racers are usually between 270 and 290 mph.

“They’re getting pretty sophisticated,” Dubbin says. “You can spend thousands and thousands and thousands a year on just trying to tweak this little part in the converter. We’ve made leaps and bounds, but we need to pick up five hundredths of a second, and we can be the quickest car in the world. We thought we were going to be there recently, but multiple things happened that stopped us from doing that.”

Racing, of course, is never simple. “We went to five finals last year and won Dallas,” he continues. “We go to Dallas this year and we couldn’t even make it 100 feet without knocking a tire off. We led it all year and all winter and then we come into the last race you could count the points for and we get sent home with our tail between our legs. Pretty disheartening right now, but everybody will regroup and we’ll be all right.”

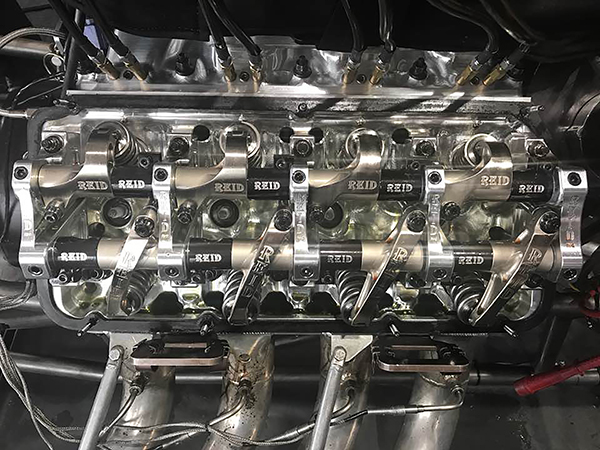

Dubbin says the majority of engines that are built for Top Alcohol racing are based on the big block Chrysler Hemi. His powerplants start with a billet aluminum Noonan Race Engineering block and matching cylinder heads.

“The majority of competitors build based off the Hemi,” Dubbin says, “though there are some variations. One of those, the Miner Brothers engine built by Bob Miner and Adam Koester, has some pretty unique characteristics.” For more information about other engines built for Top Alcohol competitors and tractor pullers, see Engine Builder’s March 2019 issue, “Power To Pull,” page 78.

Dubbin says in addition to building his own engines, he supplies power to a few other competitors as well. “I do build motors for a couple of other guys who run in our class. They’re not out there every weekend, so to speak, like we are. Then I’ll build motors for a couple of the guys on my team for their Top Dragster stuff – that’s just the next class down.”

Dubbin says his shop is capable of completing most machining operations needed. “We will do everything but line boring or crank grinding. We have all the equipment and experience for cutting valves and doing valve jobs. Luckily, on these engines, the cylinders all have liners. We’ll just put sleeves in, but we’ll machine them prior to putting them in. We do that in house as well.

Some people familiar with televised drag racing coverage see Top Fuel dragsters and Funny Car engines being completely torn down between runs. The incredible stresses in the Top Fuel engines aren’t quite as violent with Top Alcohol, so the service requirements aren’t as great.

“Typically, at the track, we completely service the motor, which entails that we pull all connecting rod bearings and measure them,” Dubbin explains. “Sometimes we’ll change head gaskets, just to adjust horsepower or compression ratio. For the most part, though, if something doesn’t go wrong in the fuel system, you’re not burning pistons every run. You WILL burn pistons, guaranteed, but not every run. Otherwise, you better back your tune up a little bit.”

Dubbin explains that the bearings can give him all the information he needs for an exceptional tune.

“Yeah, we check the tune up, by the upper rod and lower main bearings. The rod bearing tells us pretty much everything we need. That’s how you tune the car. The more you squash the rod bearing, the harder you are on that cylinder.”

Dubbin acknowledges that his mechanical tune may be unfamiliar to many who may think electronics are required.

”That’s how I started out back then. We’d put in a shorter connecting rod in those cylinders – 20-, 30-, 40-thou shorter connecting rods in those certain cylinders, and them make them all happy and even and you’re good to go,” he says. “People would look at us like, ‘wow, doesn’t that throw off the balance?’ Let’s be honest – at 10,600 rpm we shift. At that, you want the balance as close as you can but at 10,600, all bets are off.”

Dubbin says his car takes two shifts per run. “Years ago, you were guaranteed to break something nearly every run – you’d wreck push rods, valve springs, rocker arms almost every pass. But the parts have evolved so much, especially the last six or seven years, that it’s incredible.”

Dubbin says the network of parts suppliers to the Top Alcohol community is fairly limited. “To be honest, it’s a pretty tight group out there. Teams and engine builders know who’s got the best parts – they’re on display at the races each week. But the PRI Show is a good way to keep up on that stuff.”

Even though the supplier network may still be small, Dubbin says that over the past decade things have evolved dramatically, meaning choices and quality are better than ever. This gives racers like himself better chances to compete from year to year.

“Quite a bit carries over from season to season nowadays,” Dubbin says. “Just six or seven years ago, no, that wasn’t the case, because the availability of better parts just started to open up.”

Dubbin says his suppliers have come up with great engine parts and assembly tools to keep his race team in the winner’s circle.

“A HUGE thank you to our sponsors that make this possible: DMP Awnings, Central McGowan Welding and Automation, Jamie and Renee Noonan at Noonan Race Engineering, Kelly O’Tool at Aluminum Cabinet Company, Chase Copeland for building an awesome car, Jeff and Mike at B & J Transmissions, Steve, Brock & Blayne at Quick Drive, Anthony at MGP, Paul Lair at Engineered Seals and Components, Dave at Goodson Tools, and especially Karen Dubbin for taking care of us,” Dubbin says. “None of this would be possible without all the support.”