Engine of the Week is presented by

If you grew up in a certain era, chances are pretty high that you had a big wheel as a kid – or you were jealous of the kid who had one. Remember those? Joe Irwin certainly does. Unlike most of us who would ride around in the driveway or the cul-de-sac, Joe remembers riding his big wheel through his grandfather’s engine shop, dreaming of going even faster thanks to all the engines he would see.

Joe’s grandfather ran Custom Engine Service located in Hialeah, FL, and his dad also worked at the shop as an engine builder. According to Joe, they mainly specialized in offshore race boat work.

“MerCruiser was one of the engines that they did,” Irwin says. “They essentially had a remanufacturing side of the shop and then they also had a custom side of the shop. My dad worked there as an engine builder, so I grew up around race engines my whole life. I’d ride through the assembly room on one of those three-wheeled big wheels when I was probably six or seven.”

Those early influences were all Joe needed to understand he also wanted to become an engine builder one day. In fact, Joe says the only kinds of jobs he’s ever had were working in machine shops or engine shops. “It’s pretty much the only thing I’ve ever done,” he says.

Joe started his own engine shop, Fast Forward Race Engines, in 2009 with a business partner. In those early days, Fast Forward Race Engines, located in New Port Richey, FL, mainly did custom drag race engines for heads up classes. However, after about six years of doing the drag race stuff, the shop got into doing contract work for other shops.

“For about 10 years, we’ve been doing Induction Performance’s 2JZs in batch runs of 10-12 engines at a time,” Irwin says. “Once we started doing that and we saw it was somewhat profitable and a little bit easier to get through the shop because it’s multiples, that’s when we went that direction and started finding platforms we could do multiples of.

“Now, we do the 2JZ engines for Induction. We do a lot of Coyote engines. We also do some GT-R VR38 and VR30 stuff. It’s all mainly volume work now, but still high horsepower stuff. Everything is all high horsepower stuff over a 1,000 horsepower, it’s just batch runs rather than individual, custom stuff.”

Regardless of the engine type Fast Forward Race Engines is building, all of the work is done in-house as the shop is a full machine shop with manual Sunnen machines for honing and a T&S 1000 four-axis CNC machine for doing sleeve work and block work. The Florida shop has six employees who work in the 5,000 sq.-ft. facility.

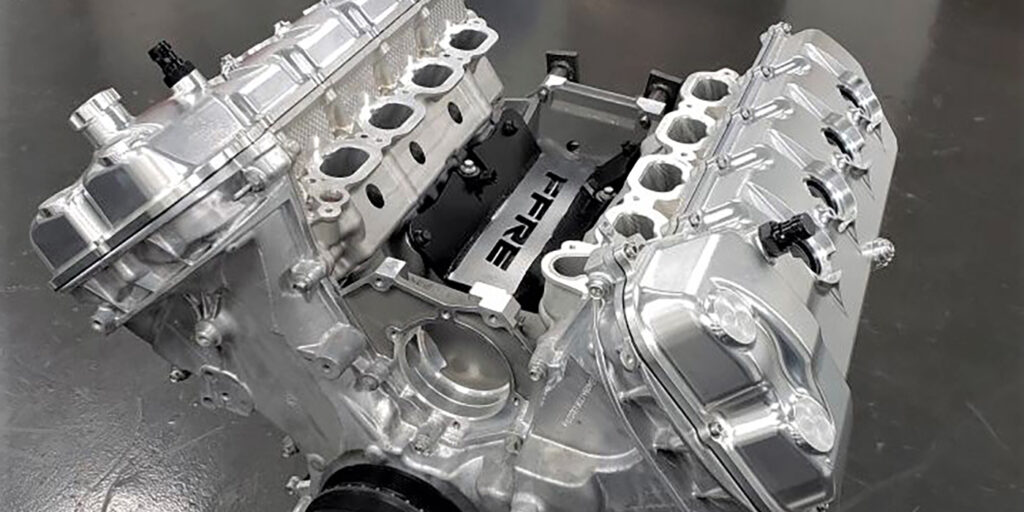

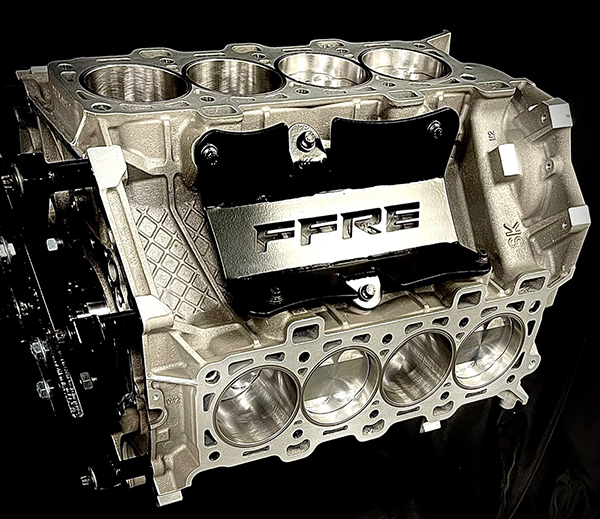

One of the engine platforms that has proven very fruitful has been the Ford Coyote and GT500. According to Irwin, Fast Forward builds these for several shops, and one of the ones they recently finished is a GT500 short block that gets built to handle over 2,000 horsepower.

“We do a lot of short block builds,” Irwin says. “This one features billet main caps, a brand new GT500 block, Manley 300M rods, Manley flattop pistons that are 10:1 compression, and Trend TP1 wrist pins that get DLC coated.

“This short block deal is good to 2,000 horsepower or more. We recently had Brett LaSala at FL2K go 201-202 mph with this short block. We had another customer win the Outlaw Street class in FL2K with this same short block. I think he went 7.0s at 198 mph with it. It’s a really good product.”

To make this GT500 short block as stout as it is, a lot of quality work and components go into it. It all starts with the block that Fast Forward Race Engines gets from Ford Performance.

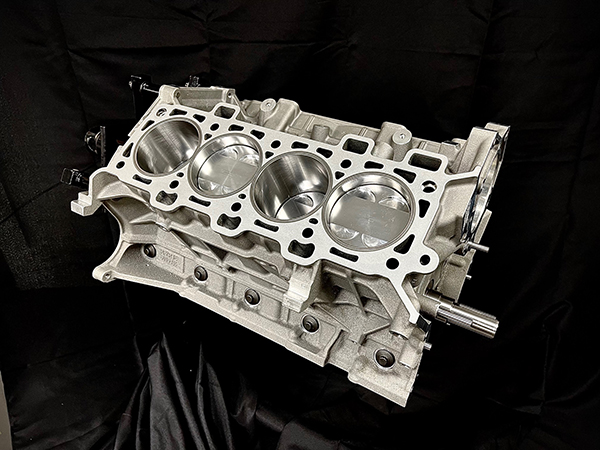

“We take the block and we completely deburr it,” he says. “We fill the coolant crossover that goes in between the cylinders with a two-part epoxy. Then, at that point, we bore it for sleeves.”

Joe says they hone the parent bore in the CNC machine to get the actual press that they want. Then, they take all the sleeves and measure each one in six spots and divide by six to get an average number. That’s how the shop batches its sleeves.

“Essentially what we’ll do is we’ll take all our sleeves that we get in and we’ll batch them in the same sizes because they’re all different sizes,” he says. “We’ll get as many the same size as we can. Then, after its bored for sleeves, we’ll leave about .001˝ in it and we’ll actually hone that block to get the exact press that we want. That’s one thing we do differently.

“The second thing we do differently is we use no Loctite to hold our sleeves – it’s all done off of press – and we install all four sleeves in at one time in a heated block. Most people do one or two at a time, so they can line the flats up. We do all four, so we have an installation plate that I made.”

After the block cools off, they seat the sleeves using a torque plate and then the shop will deck the block.

“We deck it, we hone it and we o-ring it for stainless o-rings,” Irwin says. “We still use an MLS gasket, but we only leave the o-ring .003˝ out. After the block gets the final machine work, it gets line honed with ARP main studs. Then, it gets a final cleaning and the block comes in the assembly room.”

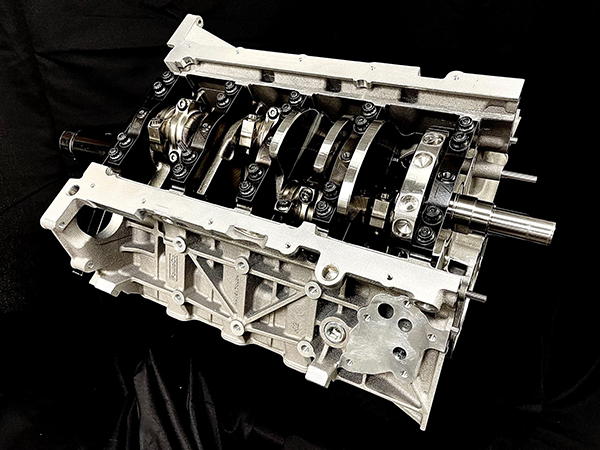

Irwin says every set of rods and every set of pistons the shop uses gets pin fit. The crankshaft in this particular build is a Ford Performance Boss crank that will get balanced using two pieces of mallory – a 1˝ piece of mallory in the front and in the rear.

“Once the engine comes in the assembly room, we leave it in the assembly room for a minimum of four hours before we start measuring on it because of a temperature differential that we see through the shop and the assembly room,” Irwin says. “After that, we start our bearing clearancing with King XP bearings and filing our Total Seal rings, which are an AP top ring and a Napier second. Then, it’s on to our assembly work. That stuff is fairly straightforward, but the difference is how we do our sleeving.”

As mentioned, this GT500 is usually built as a short block, but if Fast Forward Race Engines were to build out the long block, Joe says most guys opt for a Gen I, Gen II or a GT350 cylinder head.

“Usually, we’ll use a Manley or a Ferrea valve,” he says. “Those are the only two valves that we’ll use. We also use a PAC valve spring. For cams, some of the long blocks have aftermarket camshafts and some don’t. We’ve been 7.0s with factory cams in them. If we use the factory cams, we do weld the lobe to the barrel of the camshaft, the core, because the lobes are pressed onto the core and they’ll have a tendency of moving and coming loose. We’ll actually TIG weld the lobes to the core. We’ve also had guys get a set of custom COMP Cam camshafts and stuff like that, so that option is up in the air.”

Regardless of the component choices on the inside, Irwin notes that almost all of these engines are single or twin turbo builds.

“Some guys do the Whipple blowers or the VMP blower, but the majority of them are twin-turbo,” he says. “Everyone is going forced induction. We don’t build any that aren’t forced induction.”

Capable of making 2,000 horsepower and even more, this is a short block Fast Forward Race Engines plans to be making for quite some time to come.

“This is our new deal. I think moving forward next year, we’ll probably not build anything but these Coyotes,” Irwin says.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].