Engine of the Week is presented by

Since starting our Engine of the Week series six years ago, we’ve had the opportunity to highlight hundreds of engines and their engine builders. Similarly, as part of our Engine of the Year award, we’ve been able to honor the builders behind the most popular engines chosen by our audience. Jeff Baldwin, owner of Baldwin Racing Engines in Friedheim, MO, won our 2nd annual Engine of the Year award back in 2018 for a 440 LS Dirt Late-Model engine. We were able to catch up with him at the 2021 PRI show to talk about the details of an engine build his shop does a lot of work on – a 355 small block Chevy for demolition derby competition.

Jeff runs Baldwin Racing Engines along with his wife, DeAnna, and several other full-time employees. The shop, which opened in 2002, boasts 8,500 sq.-ft. of space, full machine shop capabilities, an engine and chassis dyno, and specializes in engine work for dirt track racing, drag racing, truck and tractor pulling, street/strip, diesel, and really a little bit of everything, including demolition derby as a major segment the shop serves.

If you aren’t familiar, there’s a lot more to a demolition derby than most people might think. There’s also a lot more to the engines in these high-dollar competitions than you might think.

“When most people think demolition derby, they think of the County Fair from 20 years ago – pick up a beater from the junkyard, knock the windows out and go run,” Jeff Baldwin says. “They might make it five minutes. They might make it 10 minutes. Those days, although there are still some of those shows, today’s stuff is run on national team shows all over the country. Some of the prizes are $20,000 to the winner, so there’s big money in it.”

The old mentality surrounding demolition derbies is long gone. Now are the days of 400+ horsepower engines, custom drivetrains, cradles, and reinforced cars with solid steel “pointy” bumpers. Baldwin Racing Engines broke into the derby market around 2005 with something most people were not accustomed to, reliable derby engines making big power.

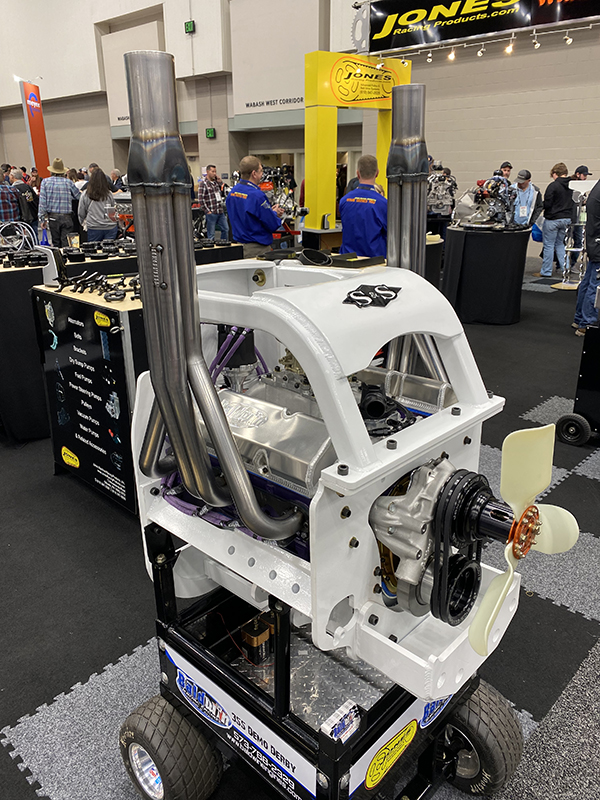

Drivers who approached Baldwin wanted one thing – an engine that would run well while hot and not die on the track. Thus, over the course of more than 15 years, Baldwin Racing Engines has continued to further develop its demolition derby engine program, and the shop brought one of its latest 355 cid small block Chevys to the 2021 PRI show.

“Derby engines are subjected to more extremes than most engines involved in competition,” Baldwin says. “We have shot engines with a laser thermometer coming off the track and seen temperatures upwards of 550–600 degrees F. It is extremely common for the cars to puncture the radiator within the first few minutes of a heat or feature, and the drivers are not going to stop or go easy on the engine. For the next 30 to 45 minutes, typically, that engine will see the rev limiter more times than you can count with no water circulating through it.

“On a stock engine, pistons will start to seize in the bores, valves will start to stick in the guides, oil becomes thin from extreme heat, valve seats start to drop out of heads, blown head gaskets can occur, and babbit camshaft bearings begin to melt.”

So what does it take to make an engine run for nearly an hour without a drop of water in it? The main goal for Baldwin is to reduce or eliminate all of the known weaknesses or failure points that are heat related.

“All blocks receive a full treatment in the machine shop, including a deck resurface, bore and hone, and a line hone,” he says. “The clearances are set looser than your average street or race engine would be. All heads receive a fresh valve job with a custom cutter we designed to help draw as much heat as possible away from the valve. Every housing and bearing is painstakingly measured during assembly to insure perfect bearing clearance. We also offer several custom machining options and thermal coatings on our high-end builds to reduce wear and heat-related issues.”

Most of the demolition derby builds Baldwin Racing Engines does are 355s. Some of them are 383s if the customer wants extra power and torque, but for the most part a 355 SBC is the top choice.

“The lower end is typically outfitted with an aftermarket crank, rod and piston assembly – some forged and some not,” he says. “Up top, we’re pretty much always using an aftermarket head to handle the heat better. We have piston cooling jets in them, roller cam bearings, thermal coatings, and anything we can do to handle extra heat. That’s the name of the game is getting these engines to run for an hour with no water once the radiator is gone. That’s the environment they live in.”

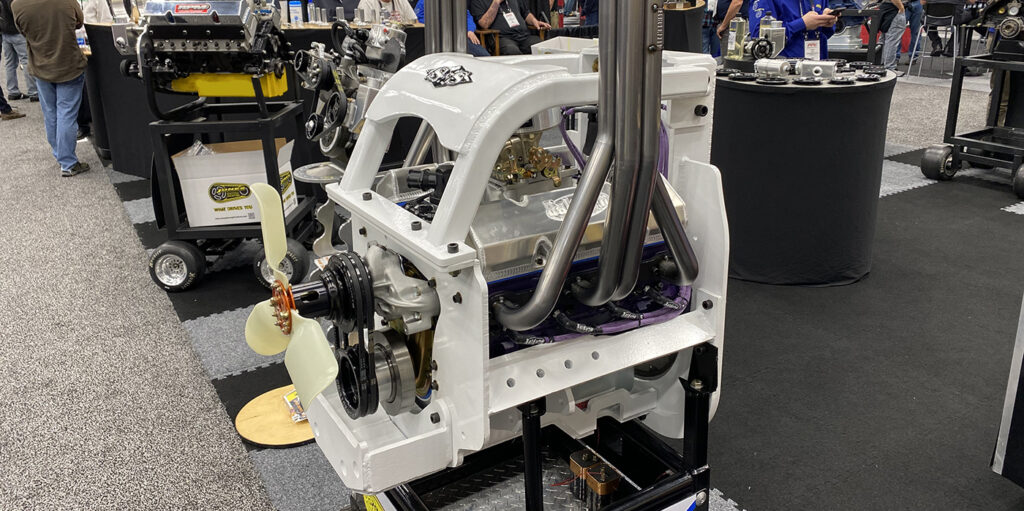

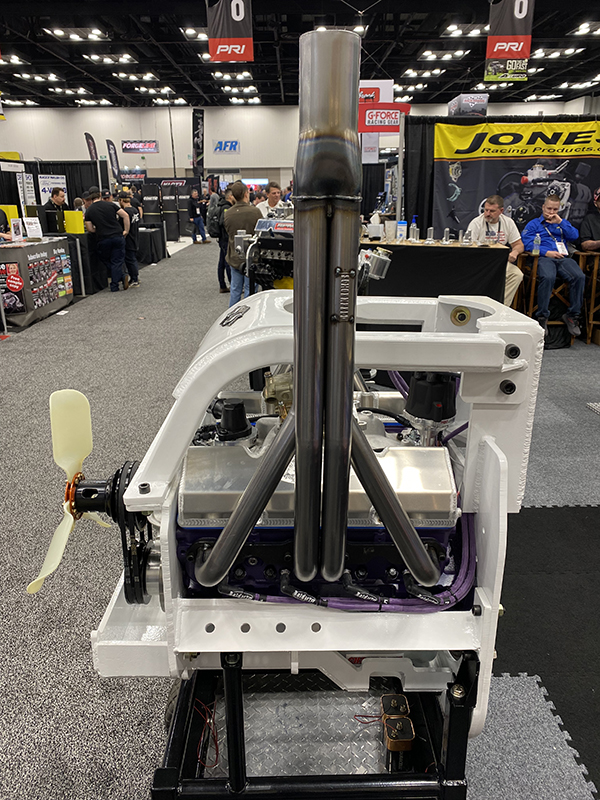

These engines typically run a two-barrel Holley carburetor built from Willy’s, and the engine cradle is made from fully wrapped, 1/2-inch plate steel and comes from Ski or S&S. This particular engine features a brand-new S&S cradle. The 355 also has a Jones drive on the front.

“We were running just a plain Jane billet pulley, but if something does get against there and take a hit, they just couldn’t handle it,” Baldwin says. “The Jones drive is obviously a lot heavier duty. It’s also hard anodized, so they just hold up a ton better. We put one of their fans on it for display. Obviously, that probably wouldn’t be part of the actual assembly because it’s too expensive and you’re going to knock the fan off every time you run it anyway.”

The headers on a demolition derby engine come straight up versus coming down out of the bottom of the car, which aids in clearance and getting heat away from everything as much as possible.

As part of the oiling system set up, Baldwin says they run bigger oil pumps, piston cooling jets and roller cam bearings to help keep things from melting.

“We do a lot of these with the oiling valve cover set up in it to keep the rockers and springs happy, and anything we can do to cool it,” he says. “Once the water is gone, the only thing we have left is oil, so we have to be able to cool it and keep it running somehow. We try to extend that run time as long as you can. The last one running cashes the check. That’s what it’s all about.”

Given the extreme conditions these engines run under, a refresh timeline can vary drastically. If they go an hour with no water, it depends on what kind of bearings they’re running, according to Baldwin.

“If they don’t have good bearings, they can’t make it as long,” he says. “We’ve had some engines that have been out there for years and we never touch them. Others get one or two runs and they’ll burn it down. It varies.”

Obviously, the performance capabilities of an engine like this are quite different than drag racing or other high-performance applications. Rather than it being a horsepower game, it’s about the endurance and longevity of the engine.

“For a long time, we were building more and more and more power,” he says. “Everybody wanted big sound, big power, etc. We still do some of those, but the sport has kind of migrated back down to more of a tame engine. These 355 small block Chevys will make 375-400 horsepower. It’s definitely not about the power. It’s about the longevity, staying out there and having endurance. You’ve got to pull compression back and use good parts internally to keep them running.”

With an engine that can do all of that, Baldwin Racing Engines’ customers are typically among the last derby cars running, which means they’re the ones cashing in the winner’s check!

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original, Scat Crankshafts and Engine & Performance Warehouse Inc./NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].