Engine of the Week is presented by

When visiting a shop like Gibbons Motorsports in Mooresville, NC, you can’t just check out one engine that they have coming together. In addition to hearing and seeing the details of a big block Chevy engine the shop built, owner Pete Gibbons also showed us a go-to package they build for UMP Dirt Modified.

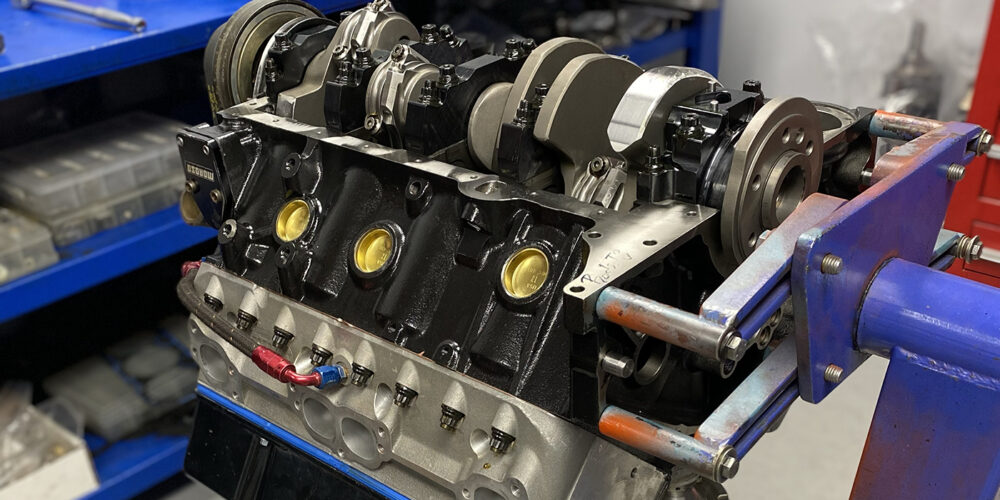

This was a stroker 421 cubic inch small block Chevy, and it was being finished up as we were in the shop, so it was cool to hear Pete talk about what goes into an engine like this one. In fact, Gibbons Motorsports does a little bit of everything from engine builds for hot rods, street cars, restoration work, dirt track racing, drag racing, grudge racing, and speed boat applications, and all machine work is done in-house.

“UMP Dirt Modified has a rule that you have to run a cast iron block and a wet sump oil pan,” Pete Gibbons told us. “Other than that, it’s wide open, so you can do whatever you want. This is a stroker 421 cubic inch block with 13-degree heads and some pretty solid, reliable components.”

The small block Chevy is based on a Dart SHP Pro block, which has a little bit bigger cam tunnel and lifter bores in it than the standard SHP, making it a good platform to start with. From there, Gibbons used Molnar connecting rods, a Molnar crank, JE pistons, a set of Dart cylinder heads, Jesel shaft rockers, Xceldyne titanium valves, Jones pulleys, a COMP Cams camshaft, and Crower lifters.

“The camshaft is about around .750 lift,” Gibbons says. “Some of these cams we’ve had up around .800 lift and usually make anywhere between 750-800 horsepower. These cars race on a little tire – around an 8” wide tire – it’s more than enough power for the tires. On something like this, the camshaft has got to be right because traction is always a big thing. A lot of guys run restrictor plates if the track slicks up.

“Guys typically run these engines up around 8,000+ rpm lap after lap, so you have to have pretty good stuff to keep them together. As such, we went with some durable Molnar rods. Those are a 6.000” rod. We generally use that length or a 5.850” rod and a 3.875” stroke. For bearings we use coated Clevite H-series bearings for the mains and rods and Dura-Bond roller bearings for the cam tunnel. For the oil pan, we either run Dan Olson or Champ oil pans depending on application. We’ve had good luck with all that stuff.”

All said and done, this is an 800-horsepower combo, and the big thing is trying to keep it somewhat smooth where it’s not out of control.

“It’s hard with 800 horsepower, but we’ve played with a lot of different cams and after some driver feedback, we found some stuff that works well,” he says. “This is our go-to package for Dirt Modified.”

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].