Engine of the Week is presented by

During our week in Charlotte, NC, we got to check out some amazing engine shops in and around Charlotte and the Mooresville area. However, there’s been an engine shop we’ve always wanted to see inside of – Noonan Race Engineering. Located just 90 minutes southwest of Charlotte, Noonan Race Engineering is headquartered in Spartanburg, SC. Being so close by and the idea of getting to see Noonan’s state-of-the-art shop space and brand-new tech center was too strong to ignore.

We took a day away from the great engine shops of Mooresville, NC and traveled down I-85 to meet with Barry Pettit of Noonan Race Engineering. We’ve had the pleasure of speaking with Barry a few times over the years, but this would be our first glimpse at the engine shop in person. Owners Jamie and Renee Noonan set up shop back in 2006, after moving Noonan from Australia to the United States.

Noonan Race Engineering specializes in manufacturing its own billet cylinder heads, billet manifolds, billet valve covers, and billet engine block designs for both supercharged and turbocharged alcohol Hemi and LS engines for drag racing applications like Top Alcohol, Funny Car, Top Dragster, and Pro Mod. The shop also does V10 engine work and is beginning to dive into Porsche engines as well.

Barry gave us a tour of the facility, walking us through the machining area filled with Mazak CNCs, the parts room shining of billet aluminum components, and the shop’s new tech center, which looked more like a NASA lab than an engine shop. To say we were blown away is accurate.

Of course, we were also treated to sights of numerous engine builds in various stages of repair and completion, Audi V10 engine dyno pulls, and completed engines waiting to go out the door.

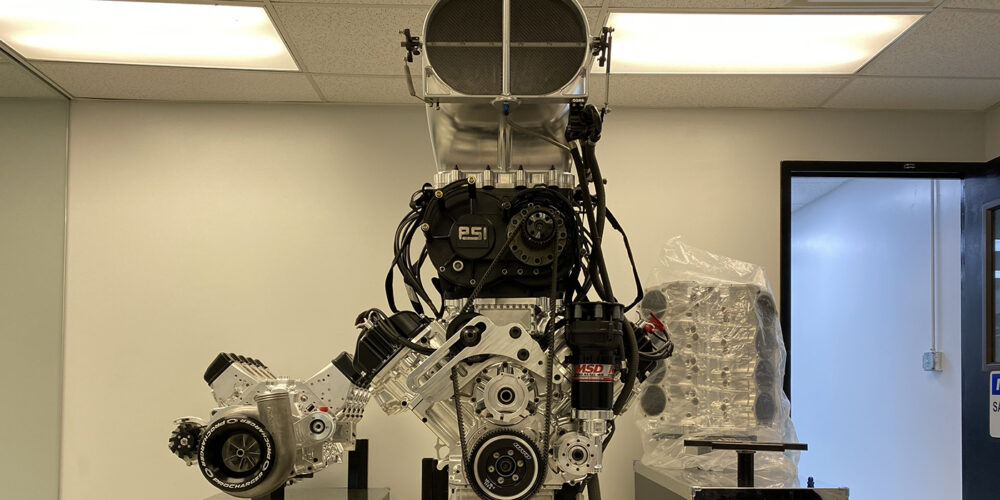

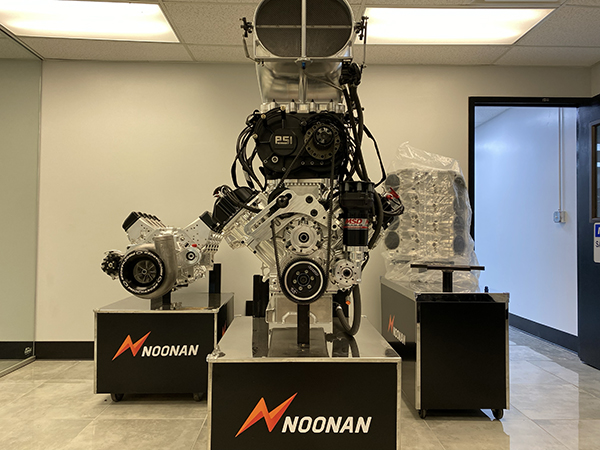

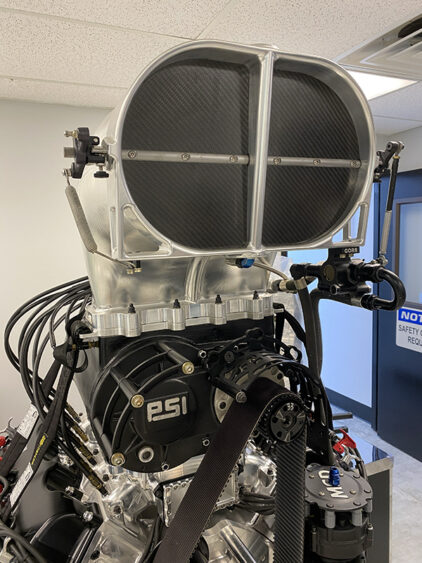

One of Noonan’s bread and butter engine packages over the years has been the supercharged 4.900” bore space Hemi engine. A shining example of one sat just outside the engine assembly area of the shop, so Barry walked us through the details of the build.

“Our 4.900” has kind of been our staple in the industry for a few years,” Pettit says. “This configuration, as it sits, is pretty much as it would be in a car. The 4.900” engine is typically a 523 cubic inch engine, and a screw blower application is the most popular. We machine the engine block, cylinder heads, intake manifold, and even the brackets for the idler assembly in-house.

“This engine has really become popular for three reasons; one is the performance. Guys who switch from the 4.800” Hemi platform will see 200 more horsepower before they really even start tuning it. Two is serviceability. A lot of the No Prep King, PDRA-type customers don’t have much time when they’re having to service an engine. One of the features of a 4.900” we like to talk about is, if say you hurt a piston ring on one of your passes, you’re able to pop the valve cover off and take the cylinder head off without removing any of this blower set up. That seems like a pretty minute detail, but when you’re between rounds, that is a huge benefit. We went about the design of this engine with that kind of serviceability in mind.

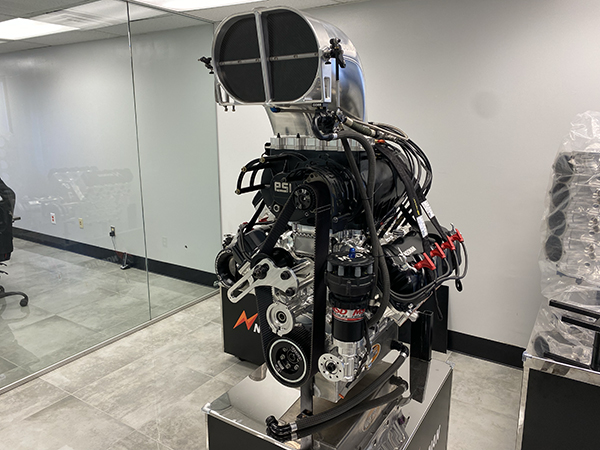

“The third reason is durability. With the increased bore center line in a 4.900”, we were able to raise the cam height up, increase lifter bore spacing and actually get the valvetrain geometry corrected, which has been a little bit of a problem in the 4.800” Hemi world for many, many years. The 4.900” allows us to fix a lot of that.”

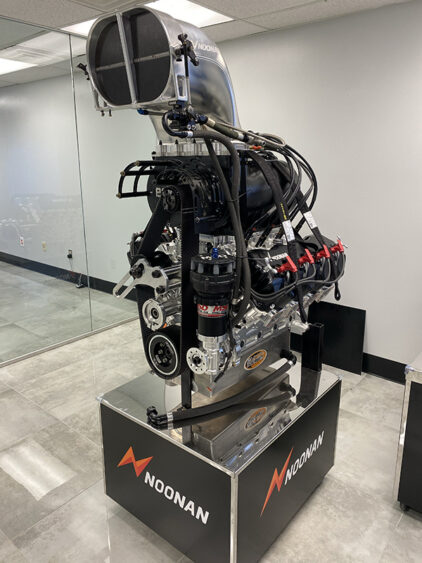

The major differences between the 4.900” Hemi and the 4.800” Hemi is obviously the increase in the bore center. This enabled the bore diameter to increase to a max of 4.600” where Noonan was limited to 4.500” bore in current Hemi applications. The increased bore diameter Noonan could run a larger intake and exhaust valve than they could with a 4.500” bore. And, not only could the shop go to bigger valves, Noonan stood the valve angles up three degrees to flatten the combustion chamber out and raise the port up an inch on the intake and exhaust. The 4.900” cylinder head changes allowed for a better flowing cylinder head on both the intake and exhaust ports.

Another big change was the lifter spacing from 2” to 3.300”. Not only does it make the valvetrain geometry almost perfect as far as pushrod angles to rocker locations, it eliminates any pushrod bulges in the intake port. It frees up the opportunity for a lot more intake port development than Noonan could have done with the 2” lifter spread in its current 4.800” Hemi.

Other significant cosmetic changes on the 4.900” engine include the 1.250” raised cam, which shortens the pushrods and stiffens the valvetrain.

Without giving away the trade secret, Barry expanded on what allows the cylinder head on a 4.900” to come off without having to remove the blower assembly, an aspect of the engine that customers have really enjoyed.

“Most of it’s going to be how the head is actually fastened to the block and the manifold,” he says. “Traditionally, a 4.800” Hemi is going to have some studs that come into the intake valley. The only way to get to those would be to go straight down through the blower and take all that stuff off. The 4.900” has 13 5/8ths head studs circling the perimeter of the cylinder head. You pull those off and then there’s five bolts along the side of the manifold. Once you get those off and you have your headers undone, you’re ready to pull the head off. It really is pretty trick.”

Like most Noonan engines, the 4.900” Hemi features a billet block, billet cylinder heads and a billet manifold all machined in-house through the use of CNCs. However, there are plenty of components Noonan still gets from the aftermarket.

“Internally, we use billet pistons, billet aluminum rods, and a billet forged crankshaft,” he says. “We’re typically using a Winberg, Bryant or Callies crank. Normally, we use Diamond pistons and R&R connecting rods. It’s very typical components – just to our spec. Due to the 4.900” bore center, you can get a little bit bigger bore diameter, so our pistons are generally bigger than everybody else’s, and we’re normally able to run a little bit less stroke than guys running 4.800” Hemis. That helps us turn our rpm. There’s a lot of things interconnected with this engine that make it a great platform.”

Another aspect of the 4.900” bore space Hemi that makes it a high-performing engine package is the valvetrain setup.

“We have a billet rocker arm assembly option,” Pettit says. “We also run Reid or T&D rocker arms on these. There’s definitely a lot of magic that happens with the valvetrain on a 4.900”, and it has a lot of stability. All 4.900” engines are going to have Jesel DLC-coated solid lifters. We’re normally going to have either a Manton or a Trend 5/8th pushrod, which are pretty big. And for valves, we’re running either a Trick Titanium or Manley valve with PAC or PSI springs.”

Moving to the oiling system on a 4.900” Hemi, Noonan tends to spec these builds with a dry sump setup, but can accommodate a wet sump if a customer wanted it.

We’re mostly a dry sump system,” Pettit says. “We do have some guys out there with wet sumps to accommodate them wanting all that weight down low. However, we mostly do dry sump systems that are two stage pumps.”

Additional components used in the build are Clevite coated bearings, a Total Seal ring pack, a custom Bullet camshaft, a Dan Olson oil pan, and a Barnes oil pump. Of course, as impressive as every aspect of this Hemi engine is, you’d be hard-pressed not to notice the huge blower on top. The supercharger setup can be configured in a couple different ways.

“On the 4.900”, with the intake manifold, there’s a plate there to make a change from a screw to a roots blower,” Pettit says. “There’s a couple of things on the bottom end that you would need to swap around, but really it makes it a versatile package. Say you’re screw blower racing and then somebody throws lead in your car, well, you can go roots racing. Change that top plate, put your roots blower on, change a couple things on the bottom end. Now, you’re a roots racer, so it really makes it a versatile deal. We do have a ProCharger manifold also.”

As far as horsepower capability for the supercharged 4.900” bore space Hemi engine, Pettit says it depends on the setup, the car and the hub dyno.

“A simple temperature swing with these engines can cost you 100 horsepower,” he notes. “Typically, on a screw blower application like this, you’re going to see anywhere from 3,600 to 3,800 horsepower. With a ProCharger application, they’re going to dyno pretty much about the same, if not more. Then, the turbo guys are going to blow it out of the water. Power-wise, they’re just always going to be making steam. I’ve seen guys well into the 5,000-hp range.”

Used in applications such as NHRA Pro Mod, Outlaw Pro Mod, and Tractor Pulling, Noonan Race Engineering’s 4.900” bore space Hemi engine has been a great staple, and it’s a combination of great engineering and great machining that Noonan says, “we’re humbly proud of.”

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].