Engine of the Week is presented by

We almost didn’t stop into Wilkins Racing Engines while we were in Mooresville, NC this summer. Not because we didn’t want to, but because the engine shop wasn’t on our original schedule. However, after passing the shop a couple times between other visits and having some spare time during our week, we found the time to walk in and see if they’d let us check out the shop.

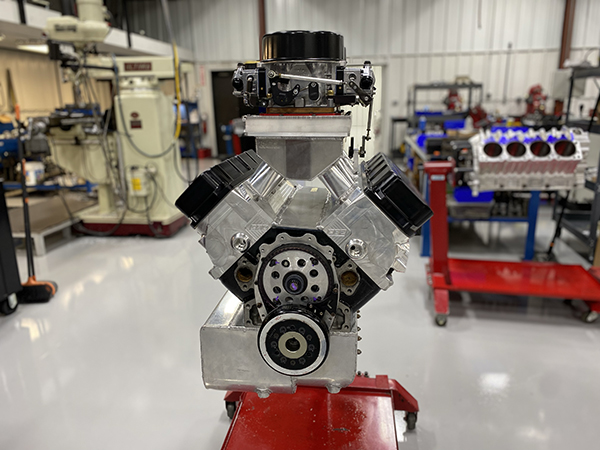

Owner Sandy Wilkins greeted us warmly and was a gracious host, making Wilkins Racing Engines one our favorite stops of the week. It also didn’t hurt that the shop was big, very clean, had some awesome machine equipment, and equally awesome engine builds on hand, like this 347 cid small block Chevy for Comp Eliminator.

Aside from this small block Chevy build, Sandy also walked us through the details of a 632 cid big block Chevy nitrous engine. His shop specializes in all sorts of different race engine applications. The small block Chevy build was for a Comp Eliminator customer, and the engine was just about complete when we were there.

“This is our first time working on this engine,” Wilkins told us. “For this build, we took parts from an old Pro Stock truck engine, and the customer specifically asked for a particular head and manifold combination. That’s what we went with and basically we filled in the blanks.

“For starters, it’s a really unique block. It’s an 8.200” deck block with a 60mm cam core and small 2.000” mains. It’s also a dry sump application.”

As mentioned, the engine was not completely finished, but it was to a point where it was ready for dress out.

“The engine features CFE billet small block heads with a CFE intake manifold,” Wilkins says. “It has a Jesel rocker system and Jesel belt drive, a Bryant crankshaft, aluminum MGP rods, and Gibtec billet pistons. The cam is from COMP Cams. They do a great job for us. We have a .937” diameter Jesel keyway lifter system. It has half-inch Trend pushrods with a ball adjuster and a bronze cup. It’s a little bit different than what you would normally see, but it’s pretty common in today’s drag racing world. Of course, we used titanium valves, but it’s a 2.300” diameter intake valve, which is pretty big for a small block Chevy. This engine should run in the 10,000-10,300 rpm range and make right at 1,000 horsepower.”

The engine’s internals were all top-notch components from quality manufacturers, but Wilkins didn’t stop there. The outside of the engine also features great parts.

“On top, we have a newer designed Holley XP, and it was brought to us by the customer,” he says. “It’s a 2.200” butterfly and it provides a lot of air for this particular application. Holley has been great with everything they’ve made, and what’s nice about these is they pretty much just bolt on and run as they are.”

From this point, all Sandy’s team had left to do was mount the motor plate, the water system, the dry sump system tank, and make the hoses.

“We have our own Goodridge hose system here and we will make all the hoses here in-house and then it’ll go to the dyno,” Wilkins says. “At that point we will know what it’s got. This customer has a number of these engines, not with this particular head combination, but they are typically 980-990 horsepower range. Hopefully, this will break the 1,000 number.”

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].