Engine of the Week is presented by

If you go back 10 years ago, a stock big block Chevy that was 632 cubic inches was absolutely huge, especially one maintaining the stock bore spacing. In many drag racing classes, the stock bore space of a big block Chevy has to be maintained. Today, these engines are known by that 4.840” bore space, and TRE Racing Engines in Cleveland, TX is a shop that specializes in building these engines.

Owned by Taylor Lastor today, TRE began operation in 1987 under Taylor’s dad Jack. However, Taylor took over from his dad in 2003 and has been running the shop ever since. The engines being built at the shop are 99% drag race and 1% street performance. With six full-time employees, TRE does everything in-house thanks to its machining and CNC capabilities. TRE also builds cylinder heads from scratch, fabricates sheet metal intakes and induction parts, and builds carburetors too.

When we got to check out the Texas shop in the fall of 2023, Taylor’s team had just finished up work on a 760 cid big block Chevy nitrous engine – quite a bit larger than those 632 cid Chevy’s of 10 years ago. He gave us the full details of what goes into what has become a ‘bread and butter’ build for TRE.

“People want to go faster than the other guys, so we went bigger and bigger, and three years ago we got Brodix to make us some aluminum blocks that were a lot taller decks, so we can make a bigger motor,” Lastor explained. “We got up to 737 cid and thought that was as big as we’d ever be. With that motor, we went out and went 3.90s in a drag radial class, which is the first stock bore space engine in the 3s. That was a huge deal. From that, we got a lot of people wanting to build that engine.

“Well, then we said, what if we go to a billet block? We get even bigger deck height and more stroke, and that’s where this has gone with the Energy and CN billet blocks – we’re up to 11.700” on the decks and 5.750” on the strokes. This engine is 760 cid and it’s still a stock big block, so it fits any kind of rules.”

While 760 cid is a huge engine, TRE is also working on an 800-plus cid big block with stock bore spacing. It has been the billet block that has truly allowed this to happen.

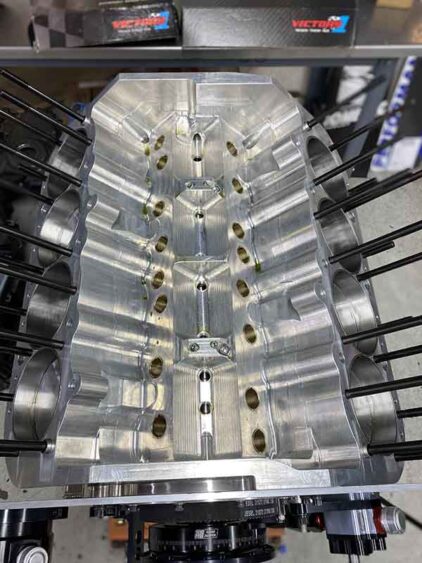

“We were doing some cast block ones that were really big, but we kind of pushed beyond those limits,” Lastor admits. “You really need a billet block. We use Energy and CN. Once we get them in, we have to do machine work to them. On some of these, the cranks didn’t fit in, so we’ve got to go in there and machine around to get clearances for the counterweights. Then, it’s a lot of rod clearancing because the stroke is so big. Sometimes, you have to cut .500” to 1”. It’s a lot of cutting.

“We finish the mains with a small amount of touch up just to get them exactly as we want them. Some we do lifter work to and have keyed lifters in some, which take a special bushing and boring. We always do an o-ring on the deck, that’s a big part of it. We then bore and hone the blocks and give them a good wash before we finish it. Even though you’re buying a $16,000 block, you’ve still got a lot of machine work that goes into it.”

Once the block is ready, TRE outfits the billet block – a CN version in this case – with quality components from a number of different aftermarket manufacturers.

“We use billet cranks for stroke this big, so Callies has a line we use, and Bryant is another billet crank we use,” he says. “Of course, we pair that with billet rods, which we buy from multiple manufacturers to be able to fill the orders. All I use is billet rods. I don’t use any forged rods. And same with the pistons. We get a billet piston made by multiple manufacturers to keep up with the demand.”

While TRE will use several manufacturers in the rotating assembly, Taylor says that changes when it comes to the cylinder heads, which is always the Brodix PB 2002.

“It’s a head they came out with pretty recently and we buy this raw and CNC all that in-house,” he says. “We’ve gone through multiple changes to get to where we’re at. We constantly try to flow more air and make more power, so we’re on probably the fourth generation of these 4.840” heads. Ours flow 625 cfm, which is up from where we started at 520 cfm. I didn’t think we’d ever get that kind of airflow out of a stock bore space head.”

As mentioned, TRE does manifold and carburetor work in-house, so this 760 cid big block Chevy also got a sheet metal intake and a billet carburetor. The carb bodies come from BLP and the assembly detail work is done at TRE. The valvetrain components are also quality parts that fit the Brodix heads.

“We use 100 percent Victory valves,” he says. “We’ve been Victory valve only for probably 20 years, and use all titanium Victory stuff. We have our own Jesel rocker system with a one-piece bar and we like a longer pivot rocker with a solid body. I don’t like a real lightweight rocker arm. I’ve found it to be a problem. We also exclusively use Jesel belt drives and use a lot of Jesel lifters.

“This engine has a 65 mm tool steel camshaft. I’ve got two manufacturers that make them for us. The lobes are all moved around to get the pushrods really straight. It’s our own core and pattern to fit these blocks. Our 65 mm cam is at about 1.200 lift with a 1.9 rocker, and you’ve got to have a really good spring to be able to put that much lift to these things – it’s pretty severe. I use PSI springs for the most part, and I use all Manton pushrods – 1/2” on the intake and 9/16ths on the exhaust.”

For oiling in an engine like this, Taylor says he’s done both wet sump and dry sump setups, but the vast majority of customers go dry sump, and he agrees that’s the way to go.

“We prefer dry sump,” he says. “It’s the ultimate. We get more vacuum too. We will pull a lot of vacuum with a five-stage dry sump, which you can’t do with a wet sump. It’s just better oiling and you don’t have the issues you do with a wet sump. We have done a few wet sumps, but you can’t put a pump internally because there’s nowhere to even drive it on the billet blocks. There’s no distributor gear and nowhere to mount a pump. If it’s wet sump, it still has to be a single-stage external.”

To match the oiling system, TRE also has its own line of oil pans – offered in both a split pan or a one-piece pan.

“People want the split pans,” Lastor says. “We’ve probably built more split pans the last few years than we did in 20 years. The split pan deal with the o-rings is pretty cool. It’s really getting popular.”

What has always been popular is making more horsepower, and TRE is no slouch in that department. These 4.840” big blocks typically feature nitrous, which TRE exclusively gets from Speedtech and then plumbs the systems in-house.

“This engine makes 1,550 horsepower with really, really low compression set up to spray 1,000-1,200 horse,” Lastor says. “The compression is in the 12s on most of these. It used to be 13:1 compression on a nitrous motor, but we’ve gone down to help put more nitrous to them. You lose a little bit of power, but gain where you can put a lot more on it. Things constantly evolve in that area. It’s not just throw it together and spray it. We really R&D on how we can get even more horsepower with nitrous.

“These big inch big block Chevrolets are making a comeback. We’ve constantly got new parts being made for them and trying stuff. Right now, we can’t build enough of them. It’s really our bread and butter.”

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].