Tips and Tricks For Quickly and Accurately Detecting Cracks

Dry Method Magnetic Particle Inspection When "Magnafluxing" a casting, never blast with media prior to testing.Blast media peens the surface and can move metal, possibly closing thevery cracks or flaws that you are trying to identify. When very coarsewire brushes are used roughly, they can also mask these areas. Usuallythe casting itself, without cleaning, is

Tips for Selecting a Valve Seat & Guide Machine

The main thing to look for when purchasing a new seat and guide machine is one that will give you the most accuracy or concentricity of the valve guide to valve seat.

Tips for Selecting Cylinder Heads

How do you determine the proper cylinder head for your application, whether for street performance, racing, off-road or other? When selecting the appropriate cylinder head/runner volume, there are a few basics to focus on.

Wiring Harness Tips & Tricks

We recently caught up with Jeremy Gibbons of Indy Wiring Services to discuss wiring looms and what engine builders need to make better harnesses for their customers.

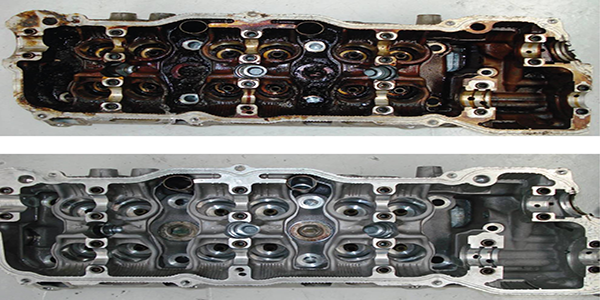

Engine Part Cleaning Tips and Techniques

It’s not fun, but vital to successful rebuilds According to a recent Engine Builder Machine Shop Market Profile, in which we survey hundreds of machine shops across the country, about 15 percent of the total production time for rebuilding an engine is spent in the cleaning process. While our wives may not agree that we

Top Tips To Maximize Fastener Performance

By Robert Florine, President, ARP Fasteners We know that fasteners hold an engine together. And that fasteners play a critical role in an engine’s reliability – especially when engines are pushed to higher performance levels. How then do we get the most out of them? At ARP, we work closely with leading race teams (Formula

QuickTime’s Bellhousing Selector Simplifies Finding the Right Bell for Your Engine/Transmission

QuickTime’s easy-to-use Bellhousing Selector puts hard-to-find and even one-of-a-kind applications right at your fingertips. Just enter your engine manufacturer, engine type, and transmission, and up pops the exact bellhousing for your specific application.

Piston and Sleeve Finishing and Break-In Tips

When finishing diesel cylinder bores or sleeves, a two or three step process that results in a plateau finish is usually best to reduce ring break-in and seating time. The type of honing stones, feed and pressure used to finish the cylinders will vary depending on what kind of finish you want to achieve.

7 Business Building Tips For The Holiday Season

Now that the holiday season is upon us, there are a number of things you can do to drive up productivity, sales, customer satisfaction and profits. Each one of the below tips worked wonders for me when I was still in the automotive business, and they are still effective today for many of our coaching clients, so I know they can work for you as well.

Tips for Planning Holiday Parties and Year-End Celebrations

‘Tis the season for holiday festivities, end of year celebrations and employee recognition, but it is also a time of year that can be a source of liability for an employer if not handled properly. Here are a few quick tips for planning the upcoming company events.

Tips to Keep the Shop Clean from Top to Bottom

To help engine and performance shops improve cleanliness and productivity, Cintas Corporation offers 10 tips for maintaining a clean shop environment. 1. Plan daily floor maintenance. Shop floor cleanliness is increasingly important as many technicians take customers into the service area to discuss their vehicle’s condition. To keep floors in the teardown/rebuilding area clean, develop

Manifold Matchmaker – Tips for Selecting the Right Manifold for Your Engine Build

Every engine needs some type of intake manifold to route air into the engine’s cylinders. With carbureted engines, the intake manifold has a wet plenum and runners because the manifold has to flow air and atomized fuel at the same time. Consequently, the manifold runners can’t turn or twist too sharply otherwise the heavier fuel

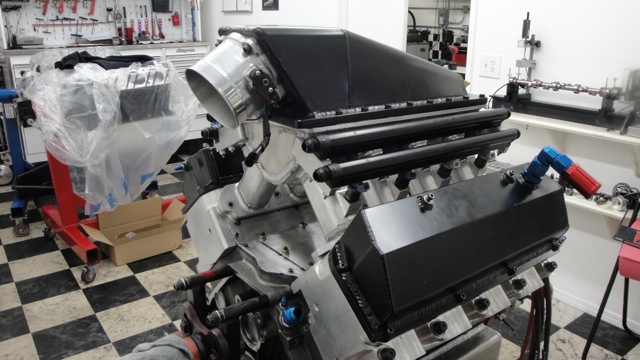

Engine Run Stand Tips

Engine test stands have evolved through development and engineering to help support engine shops, dyno testing facilities and technical trade schools, as well as manufactures. When the topic of dyno testing is tossed around, many think of exhausting every ounce of horsepower and torque. Others focus on profits and cost per hour. This is where a well-engineered engine run stand

Top 10 Tips for On the Job Safety

Are you working safely? While no one starts the day off thinking “Today I’ll ignore basic safety procedures and put myself – and my employer – at risk,” letting your guard down around equipment and heavy metallic objects (such as those in any engine building or machining facility) can result in an accident. Timberland PRO,

Spray Washer Maintenance Tips

In the 2003 Engine Builder Machine Shop Market Profile (Engine Builder, June 2003), shop owners said cleaning/disassembly were their most time consuming parts of the rebuild process. Survey respondents said that 13.8 percent of an average rebuild is spent in this area, down 2 percent from the previous year. In the same survey, 80 percent

First-of-its-Kind Compound-Turbo L5P Duramax Engine

While incredibly rewarding, nothing about this L5P Duramax build was easy for Lead Foot Diesel Performance – everything was custom or a first. From the billet crank to the one-off compound turbos, this L5P Duramax is impressive. Check it out!

Accessibility

Babcox Media, Inc. is committed to helping our audience stay up to date on the latest industry information. We strive to have our content meet industry standards for accessibility, and we welcome your feedback and questions. For feedback or problems with accessibility, please contact through our Contact Us form or call us at 330-670-1234. Be

Shop Solutions – February 2024

Submit your Shop Solution at [email protected].

Shop Solutions November 2023

Many times, the flange diameter of the rod nuts will contact the radius around the nut seat on some rods. Some jobs may not warrant the expense of spot facing the nut seat on the connecting rods. In that case, it can be quicker and more effective to just machine a chamfer on the ARP rod nuts.

The Latest on Lifters

For racing, a common trend to eliminate the problems associated with hydraulic lifters are the use of limited or short-travel hydraulic lifters. A reduction in plunger travel, which is usually about half that of a traditional full-travel lifter, reduces the amount of oil required to fill the lifter, which in turn reduces the compression of aerated oil.