Join PERA for a Webinar on Vapor Blasting Cores and Components

Before the remanufacturing process can begin, you must have clean cores. Brian Waple of ARMEX and Jeff Paduano of ESCA Industries will discuss how to use vapor blasting with baking soda to improve your current cleaning process.

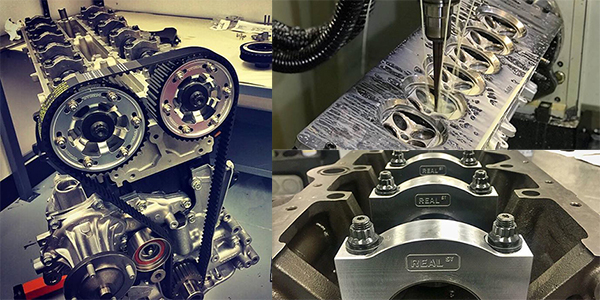

Turbocharged Toyota 2JZ Engine

When this turbocharged Toyota 2JZ engine got on the dyno at Victory Precision Machine, it lost oil pressure. The problem turned out to be a spun bearing and a trashed crank. Frank Mangano got to work rebuilding this engine for a 1997 Supra street application. Find out how the build turned out!

Safe Cleaning – Are the Concepts Compatible?

The subject of cleaning is never far from the mind of the modern engine builder or machine shop supervisor. Obviously, parts must be as clean as possible so they can be inspected, repaired if possible and reassembled. The subject of SAFE cleaning is a little less definitive, however.

ArmaKleen to Bring the Route 66 Parts Cleaning Roadshow to Chicagoland Speedway

Local business owners and their employees can bring dirty automotive parts and have them cleaned to test the performance of aqueous cleaning systems, or try soda blasting using ARMEX media in an ABS blast cabinet or Graco EcoQuip Vapor Blaster.

Blast Cabinets: Equipment, Media Options Make Quick Work of Different Cleaning Needs

No two custom engine builders use the same team to create their engine products nor do they create the same engine or use the same parts. Just like each application has different design outlines so do abrasive blasting machines that are used to clean, strengthen, shot peen and rebuild custom engines for use in vehicles from fleets to racing.

Blast Off – What’s New in Blast Media and Machines

In this industry, it’s often cheaper to remanufacture or rebuild an engine than it is to make a new one. However, doing so requires cleaning worn and dirty parts. In addition, customers these days are increasingly asking for cleaner parts and engines. How are you supposed to get tough grease, oil, rust, paint, carbon build-up,

Being Green Takes Some ‘Engine’uity

You might not have even realized, but by being an engine builder/rebuilder alone, you’re already contributing to making the environment a greener place. That’s right, it takes less energy and less material to rebuild an engine than it does to build a brand new one. So since you’re already being ‘green,’ why not go a few steps further?

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

Green Strategies: Cleaning Techniques & Equipment

It may seem that there’s nothing natural about cleaning an engine. Even after the couple of hours of cleaning time, the engine might be cleaner than the tech working on it – but the engine still needs cleaned (and so does the cleaning crew from time to time). We are long from the days of

Today

Although extremely important, the job of cleaning engine parts leaves nothing to the imagination. You’re idly standing with a spray gun in your hand or beside a washer tank or cabinet. It’s a basic, time-consuming procedure, but that grime, oil and baked-on sludge won’t come off by itself. This necessary evil is the difference

Cleaning Engine Parts: Can You? Should You?

Here’s the kicker – those shops who feel that proper cleaning is too difficult, too time consuming or too expensive are actually leaving money on table when it comes to their engine parts. “At one point in my career, cleaning seemed like it was really difficult,” says Dave Arce of Arce Enterprises, El Cajon, CA.

PRI Offers Race Engine Builders Opportunities to Increase Efficiencies, Profit in 2012

The PRI Trade Show is being held December 1-3, 2011, in the North/South Building of the Orange County Convention Center, in Orlando, Fla. It is open to the racing trade only. You must be part of a racing business or professional race team to gain admission. “The PRI Trade Show is where you go when

Cleaning Up In The Shop

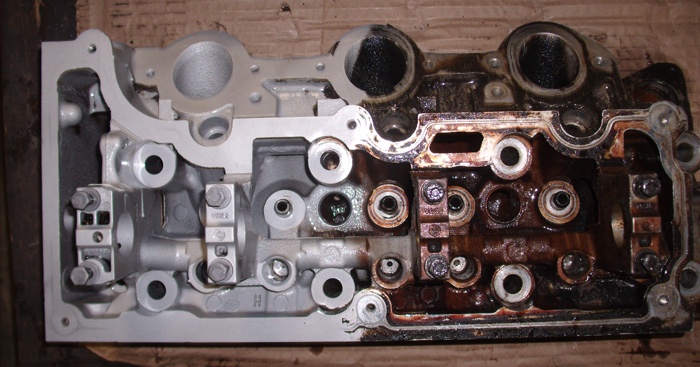

In fact, it can be very difficult to make an accurate diagnosis of what’s wrong with an engine until it’s clean. You may be able to recognize some failed parts, you can often see large cracks or obvious damage, but you’re really only assuming you know what caused a failure if you can’t see for

High Tech Cleaning Options

Yet while machining tolerances and performance expectations have changed dramatically over the past few decades, when it comes to getting parts clean, many of those high-tech shops struggle with the same technology they used 30 years ago. The simple fact is, times have changed for parts cleaning, and so have the methods. Engine builders have

Coretalk: Pentagon 9/11 Survivor To Keynote PERA Convention

After American Airlines Flight 77 crashed into the Pentagon, very close to his second floor office, LTC Birdwell was thrown to the ground and engulfed in flames. Of the burns that consumed 60 percent of his body, nearly half were third-degree burns. With more than 30 operations and months of multiple skin grafts and burn

Searching For The Complete Clean

Many shops have systems that work well for one but not so well on the other. Are there effective ways to clean both types of metal with one setup? The answer to that depends, in large part, on what you consider clean. Most shops have some type of cleaning equipment, whether it is an automated