Choosing the Correct Camshaft for the Build

Choosing a particular type of camshaft for an engine build is an important decision that has to be made before any other parts are ordered or machined. Choosing a cam requires answering some basic questions, the most important of which is the engine application itself.

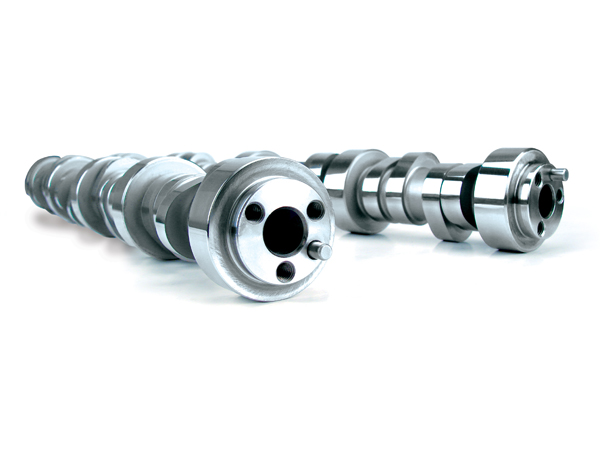

COMP Cam LSR Series Hydraulic Roller Camshafts

The LSR Series is a lineup of hydraulic roller camshafts featuring COMP Cams’ most modern lobe designs for popular GM LS engines. Designed specifically for radical street performance and all-out race applications, these aggressive-profile cams take advantage of today’s newer, better-flowing aftermarket cylinder heads. The LSR Camshafts feature higher exhaust duration and overall lift, making them

Voodoo Camshafts For LS Engines

Available for GM LS engine applications, Lunati’s Voodoo series of hydraulic camshafts delivers plenty of area under the curve. This means more throttle response, quicker acceleration, more vacuum and better efficiency, combined with maximum horsepower and torque.

Put Real Horsepower Into Your Hot Rod with COMP Cams’ Thumpr Camshafts

You’ve built your dream car. Now make your dream of an aggressive-sounding, high-performance ride come true with a Thumpr Camshaft. With the combination of early intake valve opening, long exhaust duration and a generous amount of overlap, Thumpr Cams from COMP Cams maximize your engine’s nasty-idling characteristics without negatively impacting streetability. Thumpr Cams offer performance and aggressive

Choosing Camshafts – Picking Performance

Choosing the “right” camshaft is not only the cornerstone of building a performance engine, but also its centerpiece. Choosing a cam can give anyone a headache – especially if they choose the wrong cam for a given application. There’s a lot of science involved in cam selection, so keep reading and we’ll help you

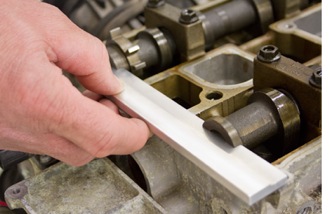

Using a Camshaft Alignment Kit to Service Ford, Mercury and Mazda Valvetrains

Locking the camshaft and crankshaft down together provides an accurate method to ensure the motor will remain in time during the repair process. The Camshaft Alignment Kit (37410) from Lisle Corporation is perfect for servicing the timing belt, chains, head gaskets or other valve train repairs on Ford, Mercury and Mazda vehicles. The kit comes

Federal-Mogul Announces Sale of its Connecting Rod and Camshaft Business

The sale involves Federal-Mogul’s sole connecting rod machining plant, located in Windsor, Canada, and only camshaft foundry, located in Lydney, United Kingdom. Federal-Mogul Corp.’s Powertrain Segment has entered a definitive agreement to sell its connecting rod and camshaft business to JD Norman Industries Inc., with an effective date of June 28, 2013. JD Norman Industries is a

Revised Camshaft Seals for Acura B18A Engine

To repair or prevent oil leaks around camshaft, use revised camshaft oil seals (p/n 91203-PR4-004). 1) Remove the timing belt and the camshaft pulleys. Note:There is a small possibility that the timing belt may have beencontaminated with oil if this is a warranty repair. Inspect the beltand replace it if it has been contaminated. See

Top Reasons and Causes for Camshaft Failure

Of all the damaged cams that Crane Cams has checked over the years, it says more than 99.99 percent have been manufactured correctly. Some people have the misconception that it is common for a cast iron flat tappet cam to occasionally have a soft lobe. Crane says they have yet to see a cast iron

Camshaft Sprocket Service for 1994 Chrysler 2.0L DOHC Engines

The camshaft sprockets on Chrysler 2.0L DOHC engines built Aug. 1, 1994through Oct. 31, 1994 may have two timing marks on the side ofeach sprocket (see Figure 1). Engine damage may result from incorrect installation of either camshaft sprocket after an engine repair. It is important that the correct timing mark is used when setting

“The Technology Behind the Multi-Lobe Camshaft” Seminar Announced for PRI

On Friday, November 30, COMP Valve Train Engineering Group Leader Billy Godbold will host a free seminar entitled "The Technology Behind The Multi-Lobe Camshaft." Fresh off their win in the "Best Performance: Street Product" category at the 2012 SEMA Show, COMP Cams 4-Pattern Camshafts will be featured at the PRI Trade Show in Orlando, FL.

Camshaft Selection

When it comes to racing, sometimes the belief is that only custom-designed parts are good enough for a winning team. The question here is, do off-the-shelf components automatically have a performance handicap? In order to get to the bottom of the “Custom Grinds vs Catalog Specs” debate Engine Builder magazine reached out to experts at

Pressurizing Camshaft Thrust Oiling On Big Block Chevys (#17)

Use a brass screw because it will drill easily. Put in the set screw withLoctite(tm) and install the metering jet. This works for many other applications where you want tometer the oil. Don’t forget to chamfer the drilled hole. Chris Muhener Expressway Machine Shop Pocatello, ID

Tuning Your Camshaft for Maximum Oval Track Power

Driver style plays a big part in the picture. A driver who can keep the rpm up in the turns will be able to use a bigger cam than one who drops a lot of rpm. The same cam in the car with lower turn speeds will not have enough torque at the turn exit

Preventing Camshaft Seizure on 1990-

The small hole in this restrictor may become partially blocked and limit the amount of oil flow to the cylinder head. Eventually lack of lubrication may cause a camshaft journal to score its camshaft bore and seize. Some engine builders drill the existing restrictor to .062? (1.575 mm) to increase oil flow to the cylinder

Camshaft & Valvetrain Technology Overview

Camshaft and valvetrain technology is a topic we’ve written much about over the years. A rotating eccentric lobe on a camshaft still opens the valves. In the case of an overhead valve engine, the cam lobe pushes a follower or bucket tappet to open the valve. With a pushrod engine, the cam lobe pushes a

Why Must I Install New Lifters With My New Flat Tappet Camshaft?

The following illustration demonstrateswhy you must install new lifters: • A new lifter has a slight "crown." A new cam has a slightly tapered face that causes the lifter to rotate. Note the smooth, wide contact patern in Figure 1. • Installing a new cam with used lifters creates a concentrated contact pattern on the

Fuel Injected Engine Camshafts

To create a vacuum signal, that stands a reasonable chance at working in an application without having to re-flash the ECM computer, a camshaft needs to be: A) Short duration, 220-222 degrees @ .050? maximum. B) Wide lobe separation/centers, 112 to 114 degrees minimum. Do not attempt to install a camshaft with a 108 lobe

Camshaft and Lash Adjuster Design Change for Ford 5.4L-3V Engine

Do not use 2005 MY parts when servicing a 2004 MY engine, or 2004 MY parts when servicing a 2005 MY engine. If parts are intermixed during a service repair, the engine may exhibit noises on affected cylinders and engine damage may result. ACTION Order and install parts for the correct model year engine. The

Hydraulic Camshafts and Lifters 101

Closing up the gap between the tip of the rocker arm and the top of the valve stem reduces the pounding effect that can accelerate valve and rocker wear. Because of this, most of the push rod engines that have been built for the last 60 years have come factory-equipped with hydraulic camshafts and lifters.