Modern Stroker Kits

Folks have been stroking engines as long as hot rodding has been around. Swapping Merc cranks in Ford Flatheads was a surefire recipe for a fast car. And as you can see from this as well as past Engine Builder Stroker Resource Guides, there is a kit for virtually any engine worth modifying.

Petty’s Garage Builds a Super Coyote to Make the MAHLE Mustang Howl

The MAHLE Mustang, the grand prize for the MAHLE Aftermarket “Drive With the Original” Promotion, is completed and ready for one lucky technician to win on October 31, at the 2017 Automotive Aftermarket Product Expo (AAPEX) in Las Vegas. The initial step in the modification of the 2017 Mustang at Petty’s Garage in Randleman, NC,

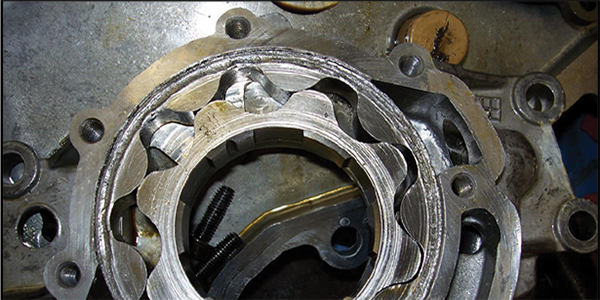

Risk vs. Reward: When it Comes to Oil Pumps, Knowing Whether to Reuse, Rebuild or Replace Can Be a High Pressure Proposition

Most engine builders appreciate how important good oil pressure is for proper engine lubrication and longevity. They also know that low oil pressure can cause engine noise, bearing failures and customer complaints that result in an expensive warranty claim.

Our Future is in the Past

As a member of the Baby Boomer generation, like many of you reading this magazine, I often worry about the next generation coming along. What will happen to all of the vast knowledge we have acquired during our lifetime and will that knowledge get passed on to the next generation?

The Valve Refacer

Let’s talk about the valve refacer. I mean you all have one. Some of you have two. My question today, is what is the program in your shop to maintain that piece of equipment?

10 Things Your Diesel Customer’s Oil is Trying to Tell You

Not only does oil lubricate as a means of controlling friction but also has to control contamination, temperature, corrosion, shock, wear, and pressure. Oil analysis is the only true way to put a set of “eyes” on the engine’s condition and the condition of the oil as to when it should be changed.

Katech Introduces ‘Sleeved’ LT1 Cylinder Block

Katech’s new “sleeved” LT1 cylinder block supports greater displacement Gen V LT1 engines and serves as the foundation for 427-cubic-inch (7.0L) engine combinations.

The Daily Grind – Grinding valve seats with different abrasives

Grinding valve seats with abrasive stones has been aound about as long as the internal combustion engine. In the early days of grinding seats, there were only two abrasive materials to choose from – General Purpose and Finishing – because seats were mostly made of a single material, cast iron. Today, seats are made of

Assembly Lubes & Break – In Oils

Perhaps the most important property of lube oil is its ability to remove heat from a surface where two or more metals are sliding across each other. In much the same way as air flows around cylinder head fins to remove heat, oil flows through a bearing and removes the heat caused by friction. I

Crank Grinding – The Myth of the .010”/.010” Crankshaft

Regrinding the crankshaft is an important part of the engine rebuilding process. It was almost an art in the ‘40s, but it’s pretty routine now. However, there are still plenty of myths and misunderstandings that are left over from the past that we still have to deal with today. One of the most common myths

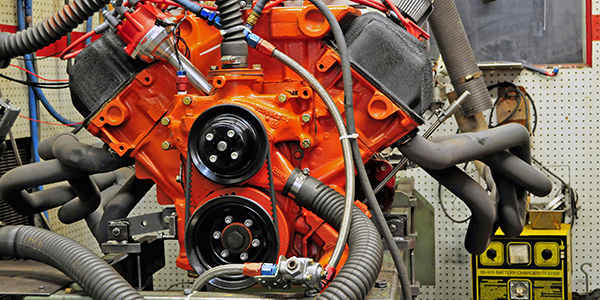

REBUILDING THE 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would

Reusing, Reclaiming, Remanufacturing – Whatever you call it, it’s how the industry recycles parts and components

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy. You’ll reuse, reclaim or remanufacture it for your specific job. Whatever the reason may

Wet & Dry Sump Oiling Systems – Choosing the Right System for the Right Job

If you are building a customer’s “dream engine” what type of oiling system should you use? The answer to that question will depend on the application (street, drag, circle track, road race, off-road or marine), engine RPM and how much your customer is willing to invest in a lubrication system. Your choices may also be

Pro Stock Quandary

One of my first writing heroes was Robert Benchley and his first book I read was when I was a freshman at LaSalle Peru (IL) High School in 1954. While researching materials to use as an exordium for an English assignment, the humor literature section caught my eye. I found Robert Benchley’s 1936 collection of

Timing Chains, Gear Sets and Belt Drives

The short answer to which type of cam drive is best depends on the application, what your customer wants and how much they can afford to spend. A stock link style timing chain is fine for everyday driving and normal use. “Silent tooth” link chains are quiet, long-lived and adequate for stock cams and valve

Turbochargers: Boost Your Turbo IQ

In the past decade, turbochargers have found their way onto more engines in cars and light trucks than ever before. By 2021, predictions by some experts cite turbocharged vehicles will reach up to 38 percent of all new vehicles sold in the U.S. Once thought of as only a means to increase performance on exotic

Head & Block RESURFACING EQUIPMENT

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head

Not Selling Short – MAR Automotive offers a full package to keep customers satisfied

Jeff Myers was asked to ride his bicycle down the street to meet up with his dad one summer day while he was home after high school graduation. His dad worked next door to an automotive shop owned then, and now, by a man named Tony. Tony ended up giving Jeff a summer job that

A Tale of Two Markets – Dealing with the Times

A couple of months ago, I approached this industry’s parts sales problem through some statistics. Now I’d like to look at things from another angle, or maybe two. I don’t think there is one reader who would argue that engine parts sales today are much different than they were even 10 years ago. Though it doesn’t

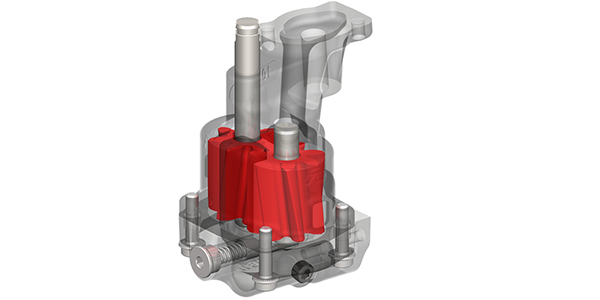

The Science Behind Wet Sump Oil Pumps & Oiling System Upgrades

All automotive internal combustion engines are equipped with some type of pressurized oiling system. Oil lubrication is essential for reducing friction, preventing wear and cooling vital engine components. Pumping oil to the main and rod bearings creates a friction-reducing hydrodynamic film between the bearings and crank that allows the crank to spin with minimal friction.