EPWI Adds FiTech Fuel Injection Product Line

Engine & Performance Warehouse has announced it has added FiTech Fuel Injection to its line card of quality vendors. FiTech Fuel Injection is dedicated to engineering, developing, and producing advanced and affordable electronic fuel injection systems.

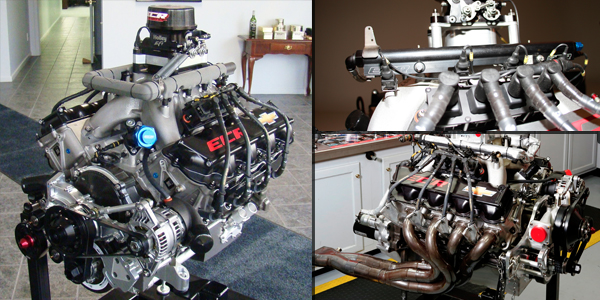

NASCAR Cup Series Chevrolet 5.8L V8 Engine

At the NASCAR Cup Series level, teams are trying to get any extra horsepower they can. Earnhardt Childress Racing uses its engine development philosophy to find half, one and two-horsepower gains for its Chevrolet R07.2 5.8L V8 engine.

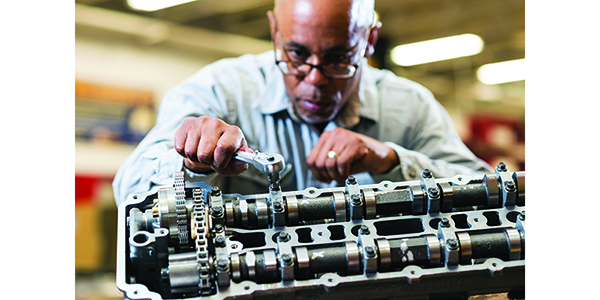

Camshaft Selection

“What camshaft should I use?” How many times have you been asked or heard that question uttered? Why is it so difficult to choose the “correct” camshaft for an engine build? What separates one camshaft design from the other? After all, isn’t it true that a camshaft opens and closes valves? Simple, right? Well let’s

Racing Rods – Engine Builders Have Options

Choosing a set of connecting rods is one of the critical steps in a performance engine build. The rods have to be strong enough to handle the anticipated speeds and loads, but also affordable for customers who have a limited budget. Most stock rods in late model engines can safely handle 400 to 500 horsepower.

Powerhouse Pinto Engine Makes 3.26 Ponies Per Cube

Doug “Burton” Brown of Fremont, WI, raced stock cars for more than 30 years before he got into land speed racing at Bonneville and other venues. In 2010, he set a record with a Datsun Z-car, and about a year later he found a Bonneville Streamliner on eBay and purchased the engine-less car for somewhere

High Performance Engine Bearings

Building a high performance engine is always an adventure. You never know how much horsepower and torque an engine will make until it’s on the dyno. And you never know how well the engine will hold up until it is put to the test on the strip, race track, street or water. The bearings that

High Performance Engine Oils

Boy, has life ever gotten complicated! Back in the late ‘60s and early ‘70s when Jim Kirby, Mike Kausch, and I were racing fueler Chevy funny cars, there were only about six American racing oils on the market. Three were produced by major oil companies (Pennzoil, Quaker State and Valvoline), and three were produced by

Going Faster in 1954

I have a large library in my office consisting of Hot Rod How-to books and annuals from the 1940s, ‘50s and ‘60s. During one of my recent review sessions I found a chapter introducing nitromethane and its use for drag racing. Keep in mind this is 1954 technology… The article began by explaining that hot rodders

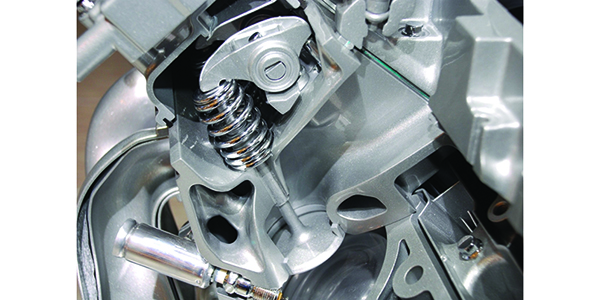

Valves and Valve Seats – There’s More than Meets the Eye

The valves and seats in an internal combustion engine play a central role in engine breathing, compression, performance and longevity. It doesn’t matter if an engine has two, three, four or even five valves per cylinder or if the engine is gas or diesel because the valves all do the same thing: they open and close to allow air into the cylinders and exhaust to exit the cylinders.

Understanding How To Tune Carburetors

An engine only runs as well as it is tuned. You can build a killer motor using all the best parts and machine and assemble everything with the utmost care, but if it’s a carbureted engine and the carburetor isn’t setup or tuned right your killer engine may never live up to its full potential.

Exhaust(ing) Your Options

Here in the pages of Engine Builder magazine we have countless articles about choosing the right set of pistons, putting in the perfect crankshaft, selecting the best connecting rods and the list goes on and on for identifying what parts and products go into your engines. However, there is one item we seldom cover –

Round and Round – Valve Timing Events and the Order of Importance

If you’ll recall, in the January issue, we got into the nitty gritty details of what makes a camshaft the “right” camshaft. In this issue, we’ll continue the education. Cam class is back in session! Remember the camshaft makes one complete revolution (360°) while the crankshaft rotates twice (720°) for a complete engine cycle. Camshaft

High-Tech Tightening – Fasteners take their rightful place of importance

When you build your engines, you put measured thought into every component you use. From the intake system to the exhaust manifold, everything has its place and nothing is installed without careful consideration. But what about the fasteners? Some of the most critical components are held together with relatively low-cost fasteners including screws, nuts and

Understanding Engine Treatments – What components can benefit from coatings? You may be surprised at the treatments available.

If you were to place technological advances on a scale, I would say that engine coatings would probably rank near the top. Engine coatings have a lot of merit, but unfortunately are often overlooked. Engine coatings have a reputation that they are only beneficial for racing applications. Yes, coatings are regularly applied and highly appreciated

Sourcing CNC Solutions – Making the decision for CNC may be scary, profitable

CNC machining equipment can be a double-edged sword to many engine builders that promises flexibility and profitability, yet often requires a significant upfront investment. As with any piece of equipment, there’s no “one size fits all” solution, and three top engine builders explain how they overcame the fear of financing and failure to find success

Camshaft Class is Back in Session

A theory prevails in which a cam lobe that opens to maximum lift and closes instantaneously is quintessential for maximum power and torque operation. Two problems exist with this premise. First, it’s highly impractical due to current technology. Second, this theory discounts a fundamental dilemma that air has momentum, and this must be utilized to achieve

Pro Touring – Engine Update

Pro Touring is the niche of niches in the performance world today. And why not, as it’s pretty much anything goes with these truly unique machines. The fundamental theory behind them is to take a car that is not historically significant and update the handling and performance with today’s seemingly endless supply of modernized parts

Cylinder Head Design & Selection

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner.

Crank Grinding – The Myth of the .010”/.010” Crankshaft

Regrinding the crankshaft is an important part of the engine rebuilding process. It was almost an art in the ‘40s, but it’s pretty routine now. However, there are still plenty of myths and misunderstandings that are left over from the past that we still have to deal with today. One of the most common myths

REBUILDING THE 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would