Computer ‘Tools’

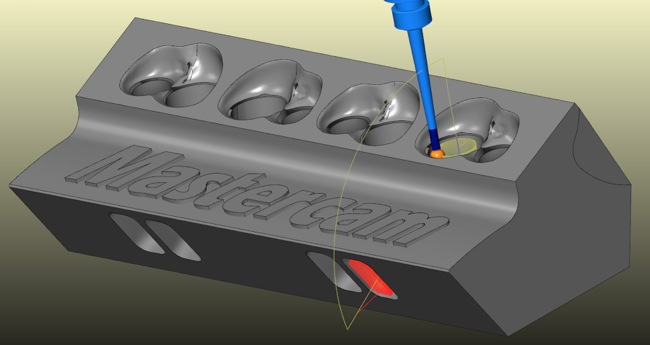

Infusing Software Technology into a Performance Build For years, computer-aided design (CAD) has been used in the automotive industry to develop prototypes of body styles, as well as to design auto components including engine parts, electronics and even tires. In fact, Dr. Patrick J. Hanratty, an American computer scientist who is known as the “Father

Shop Line

Q:I’ve noticed the main bearing bores on some Cat diesels seem to be bigger than others. Can they still be rebuilt? A:The AERA Technical Committee offers the following information regarding a main bearing housing bore caution for 1997-2007 Caterpillar diesel engines. Oversize main bearing bores have been reported during engine rebuilding on the above engine.

Shop Line

Q: We’ve had complaints of recurring oil leaks around the cylinder head on some Cummins diesel engines. Any suggestions? A: The AERA Technical Committee offers the following information regarding revised studded cylinder head bolts for Cummins 10.0L and 11.0L, L10 and M11 diesel engines. This information should be used any time cylinder head work is

Shop Line

Approximately how much can you grind off a crankshaft on a DDC diesel engine? The AERA Technical Committee offers the following information regarding crankshaft remanufacturing specifications for 1986-2007 DDC 11.1, 12.7 and 14.0L diesel engines.The crankshaft for the above mentioned 60 Series engines can be remanufactured during the engine building process. Three undersize crankshaft bearing

Late Model GM Rod Bolts

Is it okay to reuse connecting rod bolts on some late model GM engines? The AERA Technical Committee offers the following information regarding revised connecting rod bolt torque for 1997-2007 GM 4.8, 5.3, 5.7 and 6.0L engines. This information applies to all current GEN III and IV design small block engine variations. This information should

Shop Line

Q: We’ve had complaints of oil leaking from the rear cover area on some late model GM engines. Any ideas? A: The AERA Technical Committee offers the following information regarding a rear engine oil leak on 2003-’06 GM 4.8, 5.3, 5.7, 6.0 and 7.0L engines. Upon initial inspection, this oil leak seems to be

Shop Line

The AERA Technical Committee offers the following information regarding a cylinder head bolt caution and installation for 2001-2002 Kia 1.5L DOHC engines. Information published in the 2001 and 2002 service manuals for this engine is inaccurate. The 2001 Rio service manual incorrectly specifies the cylinder head bolt torque values as 36.1 in.lbs and 18 in.lbs.

Shop Line

Can you tell me if there is an updated exhaust manifold torque specification for GEN III engines? The AERA Technical Com-mittee offers the following information regarding exhaust manifold bolt and torque update on 1998-2003 GEN III 4.8L, 5.3L, 5.7L and 6.0L engines. A new exhaust manifold bolt and torque specification was introduced to the GEN

Shop Line

What is the proper main bearing installation procedure for Chrysler Hemi engines? The AERA Technical Committee offers the following information regarding crankshaft main bearing installation procedures for 2003-’06 DaimlerChrysler 5.7L and 6.1L Hemi engines. This procedure is for crankshafts previously removed from the cylinder block. It is important to first clean all of the oil

Shop Line

Q. While working on a 2004 Mitsubishi 2.4L G69M engine, I got confused about the correct valve lash specs. Can you explain? A. The AERA Technical Committee says Mitsubishi’s published information seems to have listed incomplete specifications as two different camshaft profiles were use. The following information regarding the correct valve lash specification and camshaft

Shop Line

The AERA Technical Committee offers the following information regarding a cylinder boring caution for 1999-2006 GM 6.0L VIN U engines. These engines are the newest version of the small block series and have been commonly called Gen III engines. It has been reported that cylinder bore distortion is prevalent in these blocks. Therefore, it is

Shop Line

We’ve had customer complaints about recurring MILs (malfunctioning indicator light) on some Chrysler 3.2 and 3.5L engines. Any idea what’s going on? The AERA Technical Committee offers the following information regarding a revised valve spring for 1998-2004 Chrysler 3.2 and 3.5L VIN J, G, K, M & V engines. This revision is the result of