A couple of us here at Engine Builder magazine recently took a road trip from Akron, OH to visit Matt and Jen Dickmeyer of Dickmeyer Automotive Engineering in South Whitley, IN. The four-hour drive proved to be worthwhile as we caught up with Matt and Jen about the renovations they’ve been doing to the shop, Matt’s new engine dyno design and got some info on a 383 LS1 engine Matt rebuilt.

A customer recently brought him a Mazda RX7 with a LS1 engine in it. The engine had a knocking issue and had a few other issues wrong with it due to an improper job previously done by someone else.

“When we started the engine it knocked terribly,” says Dickmeyer, who was a 2013 and 2015 runner-up in the Engine Builder of the Year Competition. “I pulled the head off, and the LS1 in this particular car has no valve release. Whoever had the car put cams in it, and the valves were smacking the pistons. The number three piston was cracked.”

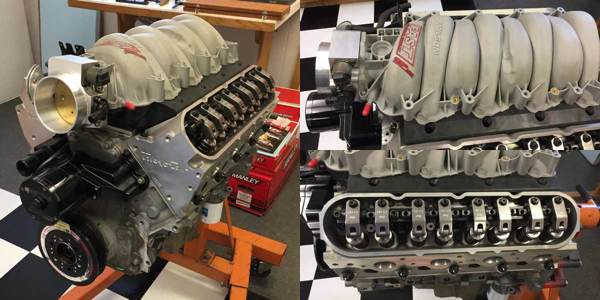

Matt admits this engine was a lot of work. The block is a 383 with a 3.905 bore and 4-inch stroke and 6-inch rod. He started out with a Manley stroker kit for it that included pistons, rings, bearings, rods, and a crank with a 4-inch stroke and large journal. Matt also used ATI dampers.

“The nice thing with these LS engines is they have a pretty good crankcase,” he says. “Originally I went high compression because it was going to be naturally aspirated. Then we did the machine work to it. The customer came back in and wanted to add a turbo to it, which meant the cam I designed and had made no longer worked because it was a naturally aspirated cam. The compression was fine because I prefer high compression, low boost. But we had to re-hone it and put sleeves in it, and go from ductile iron rings to a steel ring from Total Seal to hold up to the boost pressure.”

Dickmeyer did all the machine work in-house, as well as gas ported the upper rings and some polishing to the tops of the pistons.

“I have a specific procedure I use when I do an engine,” he says. “That way I don’t forget anything. For instance, whenever I torque a bolt I put a mark by it.”

This engine is going to be the first one Matt plans to run on his newly designed dyno once it is finished.

“My idea was to run long tube headers on it and run it on gas to break it in and do E85 and put the turbo on it and do an E85 tune,” Dickmeyer says. “This engine should hit 1,300 hp at about 12 psi. The engine is capable of 1,500 hp. Since it is a high compression, low boost engine, I’m going to run it on alcohol and the block will hold up. The customer wants 1,000 hp at the wheel, and this will easily do it.”

The top end of the engine is from Trick Flow. Matt bought the heads assembled, but first tore them down before installation.

“These heads came with all the right parts I wanted – springs, retainers, Ferrea valves – but to me, assembled doesn’t mean ready to install,” Matt points out. “I always take them apart and clean them to my standards. Very rarely do I buy an assembled head because I end up tossing out certain components or I want to swap in this or that.”

The springs are from PSI, and Matt designed the camshaft with help from Erson. “It’s a 242 242, .629 lift, 115-degree lobe separation.”

With all the kinks and quirks worked out of the LS1, the engine is now twice the power that Dickmeyer and his customer had originally planned to get.

“We were looking at getting 600-650 hp before the customer decided he wanted it to be turbocharged,” he says. “With the turbo he will easily be 1,300 hp with 10-12 lbs. of boost.”

The Mazda RX7 will be used for LS Fest-type events and will need to be strong at multiple styles of racing. “This car will do it all and can run 8.50s in the quarter mile,” Matt says.

So long from South Whitley, IN. Stay tuned to enginebuildermag.com for more on Matt’s new dyno design coming soon.

Engine of the Week is sponsored by Cometic Gasket

To see one of your engines highlighted in this special feature and newsletter, please email Engine Builder managing editor, Greg Jones at [email protected]