Engine of the Week is presented by

Working on everything from trucks to street rods and race cars, Robbie Capps learned to love cars and engines at an early age from his father. At just 13 or 14 years old, Robbie knew he wanted to turn his passion for this industry into a career. To ensure he set himself up for success, he started working at his local machine shop during high school.

“The shop owner raced circle track, so I got into doing those engines and helped with that car, and it bloomed from there,” Robbie Capps says. “It became a passion at that point.”

It wasn’t long before Robbie was being recruited to work at another shop called Cox Race Engines, which focused on late model stock builds and even called Denny Hamlin a customer early in his driving career.

“I worked there for about 12 years,” Capps says. “That’s where my race engine passion really started. That was the first facility I worked at that had flow benches and dynos and really good equipment. It was just two of us, so I had really good, hands-on learning from that.”

It was that experience that gave Robbie the confidence to start his own shop. He moved to Tennessee in 2008 to do so, however, when the economy crashed, Capps’ new engine shop couldn’t make do.

“That didn’t turn out well, so I came back to [Asheboro], North Carolina and started Capps Performance Engineering just a couple years ago,” he says. “I had a small garage and I started buying equipment. I kept building it up and building it up. We build high-end street car stuff and drag race engines. I’ve done everything from Hondas to LS engines. I’m a big Ford guy, so I really like the Coyote stuff.

“I don’t really have a niche because I got burned by that before when the economy turned south. I decided not to do that ever again, so I’ll do whatever comes in the door.”

Robbie has the capability and know-how to do machine work of all sorts, but his shop currently isn’t set up with all the necessary machines, so he sends out machine work to other shops such as Newcomb Performance.

“In the next two years, I’m planning to look at some CNC machines,” Capps says. “I’m trying to do it slowly without being $1 million in debt. I don’t want to be in that predicament again.”

Helping Robbie and Capps Performance Engineering get to the point where CNC machines can be added to the shop are paying customers. Recently, Robbie restored a ‘73 Z/28 Camaro and built a 383 cid small block Chevy engine for the customer who is also one of Robbie’s high school friends.

“He bought the car when he was 16 years old,” Capps says. “It’s a ‘73 Z/28 Camaro and it’s all originally. What we tried to do was make the car look all original, but took all the performance parts of the car – the engine, transmission and rear end – and upgraded those areas without taking away from the originality of the Z28.

“It’s a super, super nice car and it’s really turned out well. I did a high-end 383 and it turned out really, really nice. He’s got about $15,000 in it. As far as block work, I actually took a stock, two-bolt block because I like the two-bolt foundations better. I put billet splayed four-bolt caps on them because the two-bolt blocks have more main webbing at the bottom, but have a weaker two-bolt cap.

“From there it got line honed and bored using torque plates. I had the lifters aligned. I had the cam tunnel done and put in Dura Bond cam bearings. Aligning all that up really made a difference in terms of freeing up horsepower.”

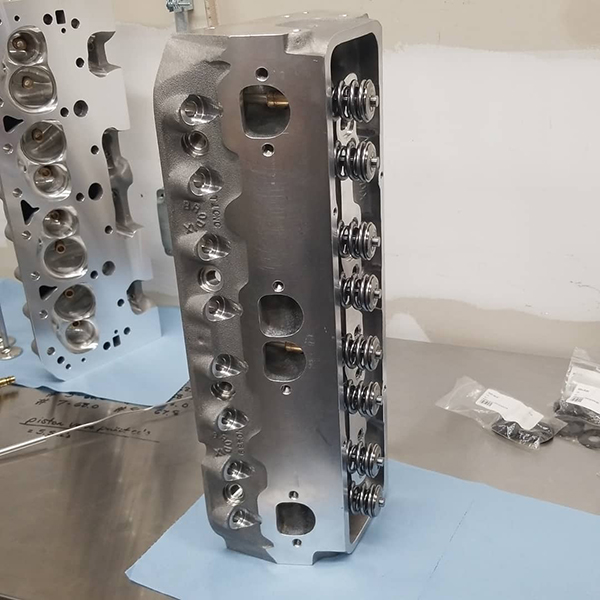

The 383 cid Chevy engine also features Brodix heads, a Scat rotating assembly, Wiseco pistons, gas-ported rings from Total Seal, a street manifold, and a QuickFuel carburetor.

“I didn’t spare any expense as far as the cylinder head and camshaft package,” he says. “It’s got a really trick camshaft in it, which is a dual pattern cam with a dual-plane intake. As far as dyno numbers, that really made this engine great.

“For valvetrain components, I used a Manley intake, PSI springs, Xceldyne titanium retainers and locks, and a T&D shaft rocker system. I used a Rollmaster billet timing set. I used high-pressure oil pump and a Champ oil pan, which has a stock look, but has a windage tray and trap doors on the inside. With the 383 having so much stroke, a lot of times it’ll have windage, so that’s why I went with that particular pan. I didn’t want to take away from the original Z look.”

For final touches on this 383 build, Capps went with an E3 ignition system – a billet distributor and spark plugs, as well as PennGrade1 for oil.

“For oil, I use PennGrade,” Capps says. “I used that stuff back when it was Kendall GT1. I love the original green oil. It’s wonderful stuff.”

On the dyno, using smaller headers, the 383 cid small block Chevy engine produced 565 horsepower and 570 ft.-lbs. of torque.

“That’s really good for 383 cubic inches,” he says. “We put the engine in the car last weekend.”

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].