Many of your customers believe that OEM parts are better than aftermarket parts. We wanted to dispel some of the myths once and for all. Without getting into the mud about which brands are better. It is important to note that not all parts are created equal, and this includes both aftermarket and OE replacement parts.

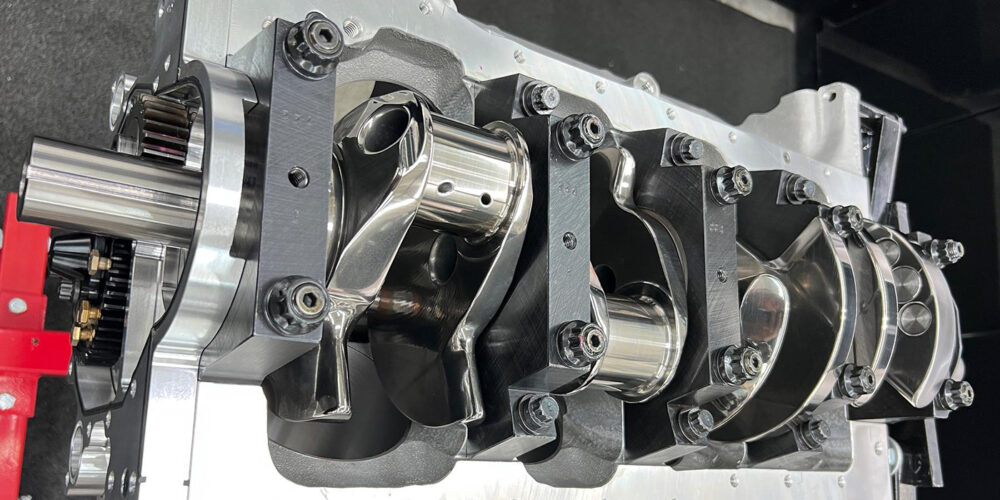

In the pantheon of parts suppliers, OEMs are customers as well as manufacturers. Since automakers don’t make every part, using suppliers that specialize in things like oil pumps, pistons, crankshafts, gaskets, among others, makes good economic sense.

These companies are OEM partners (or preferred vendors) that make up a large percentage of the total vehicle build. However, many of the OE suppliers also sell parts intended for the aftermarket.

Joel Terry, president of SB International, says there are differences between a few of the parts they provide to OE customers and aftermarket customers. However, not in dimension or dimensional tolerances. “Those are sacrosanct,” he affirms.

The differences are metallurgical, according to Terry. “There are small variances in the elemental percentages that make up a particular alloy. The slight variances are enough to avoid OE intellectual property infringement without affecting the integrity of the part.”

Jason Thompson, vice president of engineering and product development for Cloyes, says the products they produce for the OEs don’t always directly translate to their aftermarket line. “There are products that we have to reverse engineer and design in the aftermarket to provide complete systems that we are equipped to produce ourselves on the original equipment side.”

Thompson says Cloyes’ specialty on the original equipment side is sprocket production and a little bit of chain production. But when it comes to tensioners and guides, it’s something that they typically have to reverse engineer.

“We focus on a product type or complete systems in the aftermarket,” Thompson explains. “Whereas on the OE side it is one job at a time.” He also notes that one side isn’t necessarily better than the other. But there are some key differences.

“On the OE side, you may build to a specification, or you may be doing some kitting on a system, but it’s never the whole picture and all you’re focused on for the OE are those specifications and unique components,” Thompson says. “Whereas in the aftermarket, we’re focused on complete systems of solutions for your customers. It is a different world.”

The aftermarket suffered a bad rap in the past for inferior quality parts compared to OE, due to a few companies taking advantage. Today, many aftermarket suppliers produce as good or better parts than OE quality. But getting over the negative perception can still be a challenge.

“It’s a regrettable broad brush with which the entire aftermarket has been painted,” Terry admits. “Undoubtedly, there are a few aftermarket parts manufacturers and suppliers who take shortcuts to keep costs low and margins high. This has certainly colored many rebuilders’ perception. But it’s the high cost of paying out warranty claims that keep the overwhelming majority of aftermarket manufacturers and suppliers honest in providing parts on par with OE service parts.”

Some aftermarket parts are built as a “solution” to problems with the OE parts. The companies we spoke to said they routinely look at engines with specific issues and ways that they might resolve the problem with a stronger material or design change.

“We offer several valves with amended features – alloys, fillet radii, face angles and inlays, hardened tips – that offer improved, even maximum heat/corrosion/stress resistance and mixture flow compared to OE valves,” Terry notes. “Other such examples are valve seat inserts and valve guides made of alternative alloys to that of OE for greater wear resistance – and the list goes on.”

When issues arise with an OE part, the problems may not be the suppliers’ fault. The OEs contract for the part to be built to a spec and a particular material, but the supplier may not even know the intended application.

“The OEs are pretty clever,” says Thompson. “They don’t want you to know everything. For the aftermarket, we’re very oriented to a product line. We’re focused on the technologies involved in these complete systems. So, our reverse engineering covers, technical specifications from knowledge and molding to hydraulics for tensioners to chains. There’s actually a lot of complex geometry and componentry to a chain.”

Thompson says that the materials used for aftermarket products may be an improvement over OE. “One of the things that we do is find what materials work better in the aftermarket. We’re not always trying to duplicate what the OE did exactly. We also ask our customers what works well in the aftermarket.”

The two-way communication between rebuilders and technicians helps set some aftermarket suppliers apart from their OE counterpart. Companies that reach out to their customers for solutions and improvements, especially in the real-world repair environment, find better ways to build a mousetrap.

SBI’s Terry says that while the OE replacement part sets the standard. It can always be improved. “Originality has built-in cachet; it’s the standard by which all derivatives are measured. However, from a practical standpoint, especially concerning value versus price, OE superiority—real or perceived—is a moot point to a lot of smaller shops.”

In some cases where the OE may use a powdered metal product, an aftermarket supplier may convert it over to a forging or machined product. On the GM Ecotech, for example, Thompson says Cloyes has simplified the components. “On an aftermarket repair, the reasons for complex features that were needed for a new GM car are no longer factors when you’re repairing a vehicle with 100,000-150,000 miles on it. We take complex features away and make a simple replacement part that has or much more durability than the OE part.”

Sometimes aftermarket suppliers will strip down the part to just what is needed to come in at a competitive price compared to the OE replacement part.

“We use materials and tolerancing and things that have historically worked well for us in the aftermarket. It’s not always about doing what the OE does and copy it. We do our due diligence and analysis to see what they’re doing, and then we apply our aftermarket expertise to that as an additional layer. A new product we offer is our Ford 5.4L VVT sprocket; It’s in no way similar in design to the original Schaeffler/Ford component, nor is it a similar to the other aftermarket products.”

Thompson explains that the new VVT sprocket is an excellent example of taking a different approach than the OE. “We’ve felt that there was a demand for us providing a complete system that was quality all in one kit. Our design is truly different than any other aftermarket designs out there and different from the original Schaeffler component. It’s going to be more durable on a higher mileage repair.”

Terry concludes that if replacement parts function as they should consistently, and are sold at a competitive price, then the perception of quality is mainly dependent on the level of customer service. “It’s as simple as that.”