Diesel of the Week is presented by

Founded in 1985, PPE (Pacific Performance Engineering) wanted to change what people could achieve with diesel performance through its engineering innovations. Working around the Duramax platform, PPE set out to significantly improve horsepower and torque at a time when there were no consumer performance options available for the new common-rail, electronic, diesel engines. With PPE’s help, the diesel revolution had begun.

PPE engineers continued to innovate, creating performance products to enhance and improve the Duramax diesel platform, systematically finding and improving the weak links, which would fail under the new horsepower and torque demands.

PPE engineers built on their successes by turning their sights on the Dodge and Ford diesel platforms too. Today, PPE offers hundreds of products engineered to improve a diesel engine’s performance from heavy-duty cast aluminum pans and covers, which help dissipate heat and increase fluid capacity, to 6mm, 5-ply silicone, 304 stainless steel Quick Release Clamps and Flanges, from the Dual Fueler to complete, custom-built Duramax engines configured to a customers specific needs.

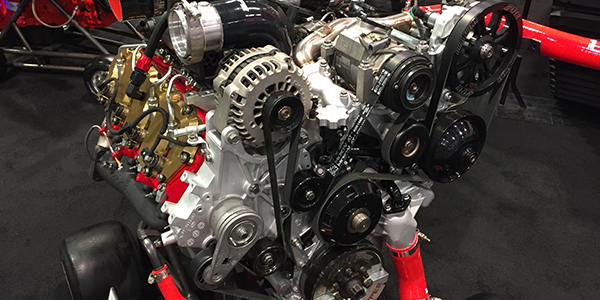

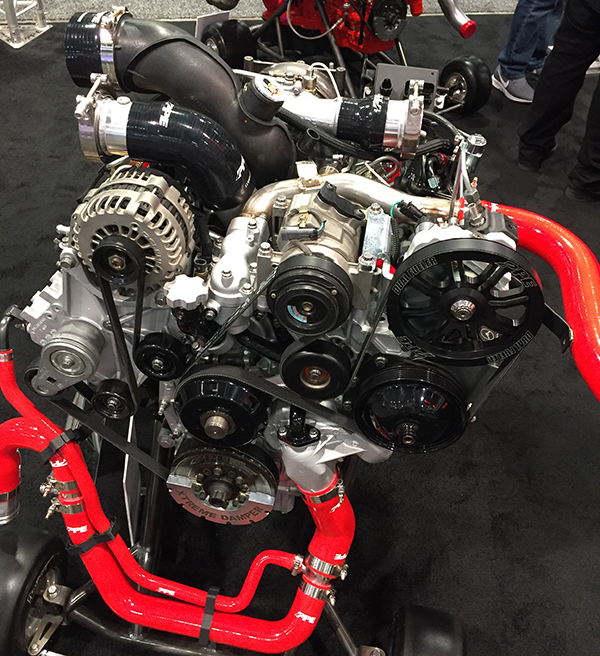

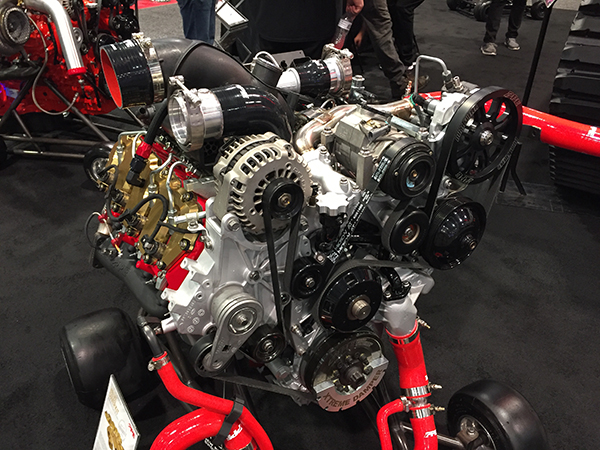

One such Duramax engine was recently spotted by the Engine Builder team during the 2019 SEMA Show in Las Vegas. We stopped by the PPE booth and caught up with R&D Manager, Corey Macha, who gave us the details of a 2007 Stage 2 Duramax 6.6L LBZ.

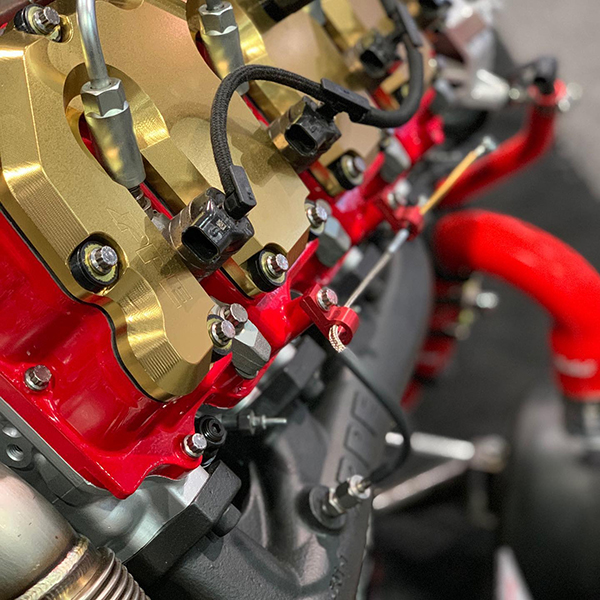

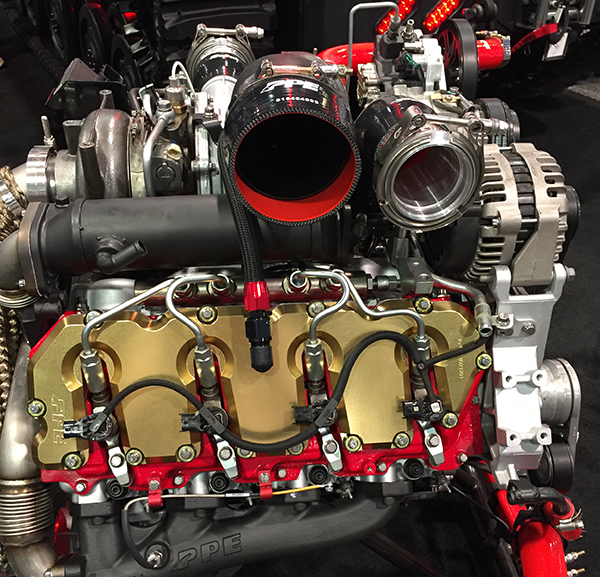

“The engine has Stage 2 heads and Stage 2 internals,” Macha says. “This year we have a new billet valve cover. On the right side is a bare gold anodize. On the left side is a black powder-coated cover with all of the factory mounting locations for your wiring harness. On the other side is your fuel filter.

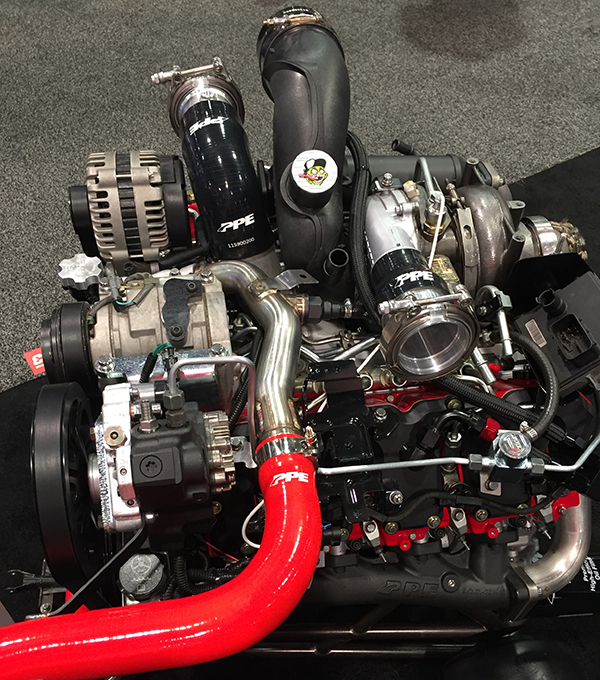

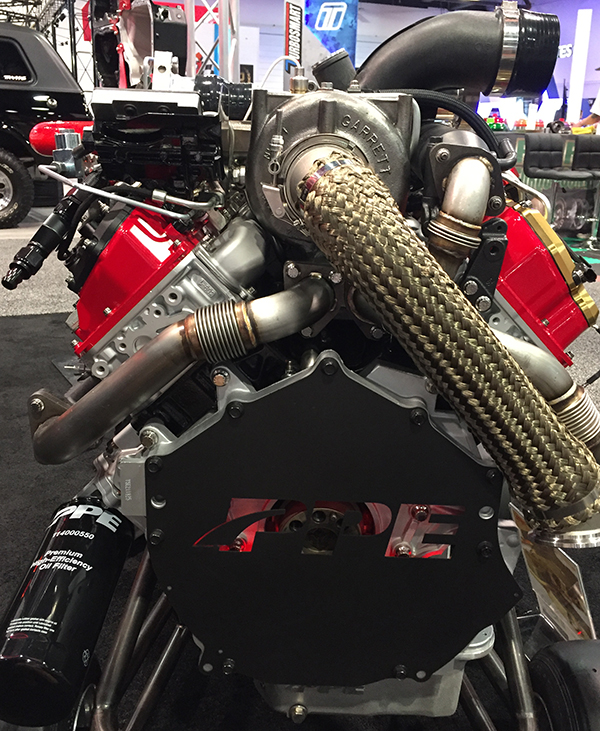

“It’s got a Garrett replacement LBZ turbocharger. It also has our up pipes and manifolds and we have a black ceramic coating new for this year – in black or silver – which will help hold the heat in your manifold and allow the turbo to spool faster.”

With diesel engines like this 6.6L Duramax, PPE is working on enhancing replacement parts from the factory that usually corrode or rust because they’re steel powder-coated.

“We’re replacing it with all stainless steel parts like the upper radiator steel tube, Macha says. “This engine also has a dual fueler and showcases a lot of our silicone products and clamping solutions for any kind of intercooler builds.”

Another special feature of the Stage 2 Duramax 6.6L LBZ is the premium, high-efficiency oil filter, which is extended length, five micron filtration.

“It comes with a magnet internally and has all of the proper valves – the leak-by valves and over pressure valves – and it’s a direct bolt-on,” he says. “What happens with the traditional aftermarket filters that are mounted vertically is they don’t have a flow back valve that traps a vacuum in your engine to hold oil in your oil galleys. Oil will flow back out of your oil galleys and every time you start your motor, you’re dry starting it. The point of our filter was to have that valve built-in.”

Internally, this Duramax is running a stock crankshaft, PPE pistons and rods and ported Stage 2 cylinder heads. According to Macha, PPE would typically mate this set up with their Stage 6 or Stage 5 Allison transmission.

“This is a new throw on an old motor,” he says. “We’re still developing parts for these motors because customers are always upgrading their older trucks. With a lot of these products you can dress up your motor, get more efficiency, go faster, make more power, and tow better. That’s what we’re all about.”

With PPE’s unique touch on this Stage 2 Duramax 6.6L LBZ, the diesel can churn out anywhere from 600 to 800 horsepower, and could go up to 1,000 horsepower using different turbochargers.

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].