Diesel of the Week is presented by

Charlie Miller and son Jason, of Miller’s Machine Shop in Lincoln University, PA, say performance diesel builds are right in their wheelhouse, but they also don’t shy away from the odd American V8, Porsche, BMW, vintage John Deere, or 3306 Cat engine as well.

Charlie Miller, the owner of Miller’s Machine Shop and the 2016 Engine Builder magazine Diesel Engine Builder of the Year winner, has been building winning engines since he was 10 years old.

“I started off pretty young,” Miller says. “My dad worked in an auto parts store and he opened up his own place, Jess Miller Machine Shop in West Chester, PA, back in 1975, out of a little one-car garage. Back then, he did a little bit of everything; old school diesels, general automotive and a lot of drag racing stuff too.”

Starting when he was 10 in about 1976 or ’77, he was working in the shop with his father, basically cleaning stuff up, Miller says. “At that age I was just interested in working on go-kart engines and motorcycle stuff, but what I was really doing was starting to learn the trade. I progressed into the bigger builds and started doing all the bottom ends on drag race motors and all that good stuff. In 1979, my dad moved into a bigger building and shortly after that he again doubled the space. In 1982, when I was still in high school, I was working for him full time through a work release program.”

Miller learned his skills at the feet of a master, he says. “I mean, back in those days, we were doing work for Bill “Grumpy” Jenkins and Jungle Jim Liberman, both Pennsylvania boys, as well as a lot of the East Coast Funny Cars and other racers. A lot of that stuff was built out of machine shops like my dad’s.”

In 2010, Charlie’s dad retired, so Charlie became the sole proprietor of Miller’s Machine Shop and works alongside his son Jason. The change from the old days, Miller says, is that diesel, not gas, makes up the bulk of his work.

“It seems like the diesel stuff is definitely taking over, at least on the performance side of it anyway,” he says. “We’re not entirely diesel, but it seems to be slowly turning that way. Within the last year I would say we’re probably 80 percent. We get very little gas stuff anymore – although we find enough gas stuff to suit most shops.”

Miller’s Machine Shop is a 2,600 sq.-ft. shop still utilizing the equipment his father started with. And as the shop’s name suggests, Miller’s Machine Shop is a full-service machine shop for cylinder head, engine block, crankshaft and internal component operations. The shop focuses on Duramax, Cummins and Powerstroke diesel engines and does their porting by hand.

“We’ve been getting pretty good numbers out of 6.0L Ford heads, probably some of the highest in the industry,” Miller admits. “Cummins heads, too, I do real well with, especially the 12 valve stuff.”

For now, the Millers service their loyal customers with high performing engines. The shop builds 30 custom gas and diesel engines a year in addition to the machining services it offers.

“My son Jason does a lot of Instagram and Facebook posts and puts stuff on our website,” Miller says. “A lot of our guys eat that stuff up! Most of our work is local, but thanks to the internet and social media we have customers all over the world.”

Speaking of the internet and those 12-valve Cummins engines, Miller’s Machine Shop did one hell of a job on a 12-valve Cummins for customer named Tony Salokas. Tony came to Miller’s Machine Shop back in 2018 wanting to get a 12-valve Cummins rebuilt to put in his ‘39 Chevy pickup rat rod project.

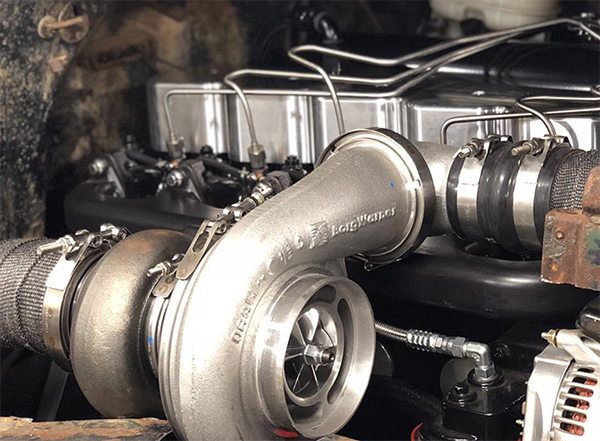

Charlie did the machine work on the block and the head to get it back in pristine condition. The build also features plenty of other goodies too, such as a Fass fuel pump, an ATI damper, a BorgWarner turbo, and aftermarket internal components.

The customer took over the rat rod build from there. Tony installed the engine and transmission into the truck, did all the wiring and got the ‘39 Chevy rat rod looking exactly as he wanted with a custom bed and everything.

The build took roughly two years to get it complete, but the time spent certainly paid off. We love it when rat rods look this good, and when you can fit a Cummins in an old Chevy, it’s even better!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].