Diesel of the Week is presented by

Joe Gillespie has spent 40 years in the engine industry, and his son Jesse, has grown up surrounded by it. Together, they run Pro Tech Diesel in Glendive, MT, a now 12,000 sq.-ft. diesel shop.

Joe began his engine building career in 1980, working on fuel injection systems, pumps and injectors for tractors. Not seeing any room for advancement within the company he worked for, he moved to Glendive, MT in 1984 and took over a diesel injection shop, running it by himself.

“I was the only person running the shop, so I had to be certified for all the different manufacturers and all the different injection pumps of each manufacturer,” Joe says. “I had to go through all the schooling, which they sent me through.

“In the ‘90s, when everything went electronic and the mechanical injection pump started to disappear, that’s when we started working on the pickups and vehicles themselves. At that point, we needed a bigger facility, so in 1995, I bought the business from Carquest at that time because that was the only diesel injection shop that they had and they didn’t want it anymore.”

Joe took over that business and started building the new Pro Tech Diesel through reputation and repeat customers. Fast forward to today, and just two years ago, Pro Tech built out a new 12,000 sq.-ft. facility and has five full-time employees and some part-time help, too.

“Now, we have a state-of-the-art facility with epoxy floors, LED lighting, air conditioning, and a showroom,” Joe says. “After that many years, to have yourself a showpiece that you can actually be proud of and have your clientele in and be comfortable about what you represent, meant a lot. We’re finally looking the part of what we’d been for the last 30 years, which is a real honor.”

Pro Tech works on mostly Ford, Chevy and Dodge vehicles with a rare Nissan or Volkswagen coming in. And while the shop started with fuel system work, it has certainly graduated to the whole vehicle.

“In our area, it’s farming, it’s agriculture, it’s oil fields, so we see a lot of crew trucks,” Joe says. “There’s a lot of pickups because that’s what everybody needs to do their jobs around here. Fuel systems are definitely our expertise, but we do everything from accessories to engines and putting in transmissions, fixing brakes, and much, much more.”

As Joe built Pro Tech Diesel into what it has become, Jesse was busy learning everything he could about engines from a young age.

“I grew up around it,” Jesse says. “I didn’t really know anything different. I remember being five or six years old and being in the shop with my dad. As I got to be 10-12 years old, I had dirt bikes and four wheelers and stuff, so I was always tearing into those and I had always been pretty good at blowing stuff up, so I had to figure out how to fix it myself.

“Later, I moved into racing quads and race bikes and stuff like that. By the time I was old enough to get my driver’s license, I think I had my first pickup for about three months and I saved up enough money to get a cam and an intake for it and I blew that engine up pretty quick. It all started to spiral from there in terms of building engines and turbocharging stuff.”

One thing Joe never did was stifle Jesse’s creativity and drive to try his hand at diesel work. This has had a huge impact on Jesse’s current ability to build durable, performance diesel engines.

“My dad never really told me no on anything,” Jesse says. “He just said, ‘Try it and see what happens.’ My dad knew by letting me do that stuff I would learn something. As I get older, I’ve appreciated that because when you’re a kid you don’t want to listen to your dad. He definitely let me fail.”

Those early trial and error builds, helped lead Jesse to sled pulling and building high-performance diesels. His most recent build is a 3.6 smoothbore charger 6.2L Cummins, which uses a 5.9L block with a 6.7L crank, but it was a long road to get to where the build is today.

“One hundred percent of that is my son’s,” Joe says. “He had a bare chassis and has built it from the ground up from the engine, the suspension, the design, the welding, the electrical, the data log, and everything else has all been him. That’s definitely the biggest showpiece we’ve got. That’s why we’ve done it over the years is to bring media to the facility to have everybody start following you and watching you. Hopefully they want you to work on their stuff because look what you did here.”

Jesse’s entry into sled pulling started in 2008, competing locally with a 2.6 truck. It was just a hobby at first.

“I always had good running diesel pickups,” Jesse says. “Then, it got to the point where people were building dedicated sled pull trucks around here. For a few years, I put on events, but I still didn’t have much intent on sled pulling. However, after a couple of years of doing events, I decided to build a pulling truck.

“We started out with a 2.6 truck, but there wasn’t enough 2.6 trucks ever to really run just 2.6 stuff. I was running against compound trucks and all that, so I decided to bump up to a 3.0 turbocharger and make a little more power.”

Going from the 2.6 truck to a 3.0 smoothbore truck wasn’t really a huge change, but he found he was changing axles and stub shafts and breaking things every time he went out.

“I got tired of that and I decided I was going to build a new sled pulling truck from the ground up,” he says. “I literally pulled the truck out of a field where it had been in a crick. The rancher or farmer who owned it, had got it stuck in a crick and the water came up overnight and flooded the truck. This thing was trashed. I figured it was just the body and it would be fine as a pull truck.

“I got it to the shop and picked up the frame to clean it up. I took all the body and all that stuff off of it to go get it ready. We spent three hours with a hose in each frame rail, pouring mud out of it. It was bad.”

Despite the rough shape it had been in, Jesse got the chassis looking really good and knew the body would have to look good as well.

“It’s a 2004 cab with 2006-style front fenders and a fiberglass hood,” he says. “It turned out to be a lot nicer than it was supposed to be. The cab is pretty much gutted down to the point where I’ve taken out weight everywhere I can.”

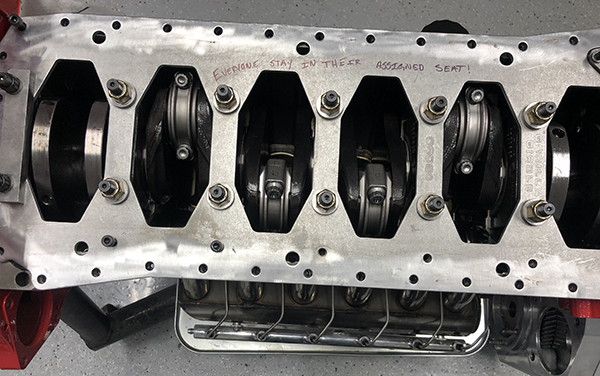

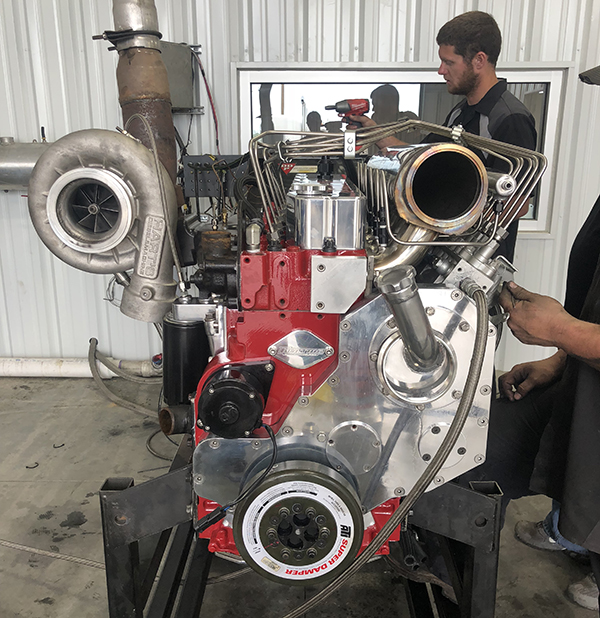

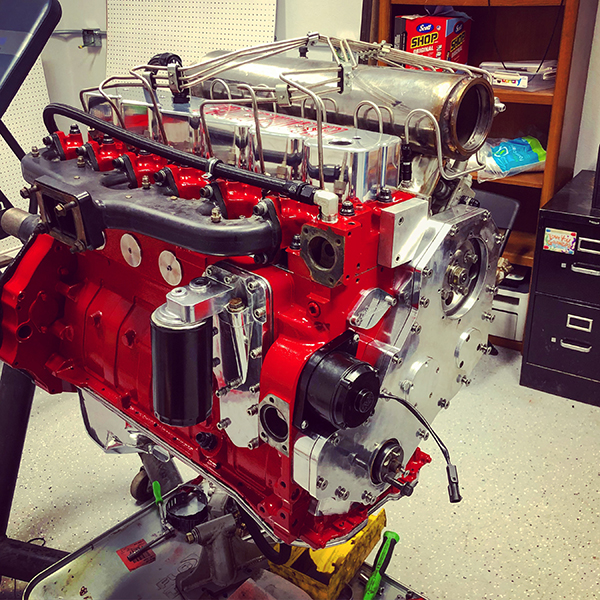

As for the engine, the build started with a 5.9L block with a regular P pump. The block is sleeved and has a 6.7L Cummins crank in it. Pro Tech also used Wagler rods, Diamond pistons and did a really nice port job on the head.

It also features a Harts turbo, a Harts injection pump, Dynomite injectors, a Precision PT 4000 water to air cooler, ARP fasteners, Mahle H-series bearings, a Scheid front cover, a one-piece billet valve cover, and a 5˝ side draft intake from Joker Fab.

“The best thing I ever did was take that thing down to Perkins Diesel and put it on the engine dyno,” Jesse says. “I think we picked up like 400 horse there. As it is now, it makes 1,680-1,690 horse.”

Helping to make that horsepower is AMSOIL, which Pro Tech Diesel has used for a while now.

“We were sponsored by a local AMSOIL dealer, so I’ve been running the AMSOIL 20w50 competition diesel oil,” Jesse says. “I have absolutely no complaints about that stuff.”

With the current 3.6 smoothbore charger 6.2L Cummins sled pull set up, Pro Tech has seen some great success, and we have no doubt the shop’s success will continue.

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].