Diesel of the Week is presented by

We recently got a message from No Limit MFG owner, Eric Staab, offering to tell us the details of a recent diesel engine he had built – a 680 cid OTTPA Pro Stock John Deere engine – and we couldn’t possibly say no to that!

No Limit MFG, located in Marshfield, WI, manufactures parts and complete motors from street truck builds, rat rods and hot rods, to fully built, turn key engines for pulling and racing. No Limit MFG’s facility has multiple CNC machines, fabrication equipment, multi-axis machines, cam grinding equipment, and engine building equipment that allows the shop to do its work almost entirely in-house.

Owner Eric Staab, much like many others in the industry, grew up with this stuff his whole life. Eric’s father started a machining company called Staab Machine Inc. in 1990 and got involved with tractor pulling on the side. This led him toward diesel engine work.

My dad was always into machining and manufacturing stuff, so that got him into making performance parts for diesel engines,” Staab says. “I grew up in it. In 1998, I graduated from high school and went to work for my dad. That’s when CNCs started to become more affordable for small businesses. My dad bought a CNC and it was my role to learn how to run the machine. I grew up in the business and have been around pulling and diesel engines for a long time.”

Eric worked for his dad a full decade, until around 2008, when he decided to split off and start a new adventure building a motorcycle trike. This led Eric to start No Limit MFG in 2010 as a way to build parts and do the manufacturing end.

“We also did some performance diesel stuff, such as camshaft grinding,” Staab says. “That’s a big part of our company. We do a lot of camshafts and we make them here completely from scratch. I started doing that for places like my dad and other engine builders.”

No Limit MFG spent its first six years leasing building space, until 2016 when the shop’s neighbors were looking to expand. At that time, Eric’s dad had also gotten sick.

“It worked out that our neighbors leased our space and we decided to move back into my dad’s facility and lease part of that shop and help him with Staab Machine,” he says. “We eventually grew Staab Machine into No Limit where we do a lot of these engine builds for tractors, truck pulling, drag racing trucks, rat rods, hot rods – you name it, we’ve done it. It’s mainly all diesel, but we do a little bit of gas stuff here and there.”

No Limit works on Cummins, Duramax, Powerstroke, John Deere, International, Massey Ferguson, and Hercules engines, in addition to parts manufacturing. Having moved Staab Machine into No Limit, the shop has three full-time employees and two part-time employees operating out of 10,000 sq.-ft. There’s very little the shop can’t do when it comes to engine building.

“We don’t build turbos, fuel pumps or crankshafts,” Staab says. “Those are the three pieces we don’t make. Everything else we do in-house. We do stock replacement engines all the way to a full, 4,000-4,200 horse Pro Stock tractors. That’s chassis, sheet metal, engine, the whole nine yards. There’s a whole gamut of stuff that we do on top of our parts manufacturing. We process lifters, camshafts and billet cylinder heads. We do cylinder head porting in-house and a lot of R&D work too.”

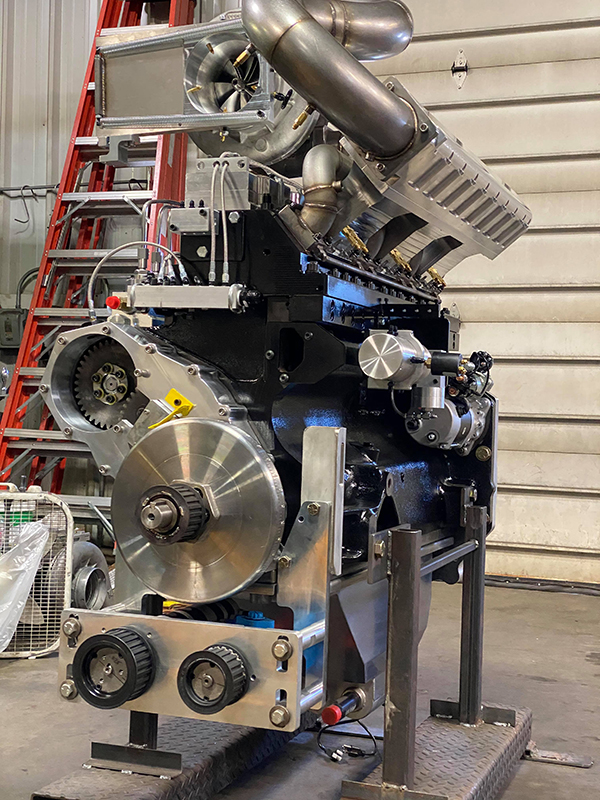

Nothing is more evidence of No Limit MFG’s capabilities than the 680 cid OTTPA John Deere engine Eric wanted to tell us about. The build was for a new customer and started with a John Deere 619, or 10.0L engine, out of a John Deere agricultural tractor.

“That’s the base platform we start with,” he says. “The customer is going to be pulling in the Outlaw Truck and Tractor Pulling Association (OTTPA). They have a Pro Stock class and the rules are for a 680 cubic inch engine. They can run a maximum of a 5˝ inlet compressor side turbo. Everyone in the class is supplied the same turbo from the same manufacturer. That’s the starting platform we have to work around.”

The Outlaw Pro Stock class with a 5˝ compressor inlet differs from NTPA or PPL in that they can use up to a 6˝ inlet and an intercooler. In Outlaws, you cannot run an intercooler.

“Those are some of the differences of what you see around the country, but basically everything else is pretty close to the same as far as how we’re building the engine,” he says. “We get the block in here and we start with an inspection process of the block. We pull all the main caps and everything that’s stock apart. Then we go in and we inspect saddle flatness, flatness to pan rail and flatness to the deck. We magnaflux the block and there’s a cleaning process in there too. Then we start on machining.

“Our blocks get cross-bolted. We’ll go in on the bottom end and we machine out the block for the billet main caps that we put in there and then rotate that block over and put our girdle plate on top. Once all that is set, it goes into a line boring process and we line hone the mains.

“Once we have that done, we flip it over, and since it’s a 619 block, we don’t have to bore the block out for the sleeves. The sleeves are a wet sleeve, which we manufacture in-house out of a high tensile, duct iron material. We make the sleeves for the bore size we’re going to run, which is typically around a 5.125˝ bore.”

Prior to putting the sleeves in, the engine will be decked and the counterbores will all be reset. Everything No Limit does is precision and all those sleeves will fit at the same height. Once that’s done, the shop goes through all the tap holes – all the head stud holes and main stud holes. They also go through and deburr and clean the block.

“It’s a very, very detailed process when we go through cleaning and deburring and making sure things are sitting proper for a precision fit,” Staab says. “Especially at this kind of horsepower, everything has to be to a very detailed. We record all of the numbers on the engine – line bore, bore finish, cylinder sleeves, etc.”

Next, the shop will get into the crank, which for this build is a billet crank from Southern Illinois Crankshaft. No Limit will inspect it and make sure it’s correct to the prints. They measure out all the journals – main and rod journals – and then put in the bearing shells.

“We used Clevite bearings for this build,” he says. “We check all the clearances to make sure they’re meeting our clearance specifications that we want to run on this engine, and then we take it all back apart. We actually assemble everything up without the crank in there, go through, measure everything. We measure all the shell thicknesses, put them in there and then we go measure the bores after everything is torqued down. Once that all fits, it comes back apart.

“Then, we go through and measure all the pistons, which in this engine are Arias pistons. We finish the piston bowls in-house. We then measure the rods and get all the rods torqued up to get the bolts stretched to manufacturer specifications. If we don’t have to make any adjustments, then that stuff’s ready to go.”

Next, the shop move to the cylinder head, which starts as a chunk of ductile iron, but not like a stock head casting. It’s a very high-end cast material.

“It’s not like what you’re going to see on a stock head,” Staab says. “The tensile strength of a stock head might be somewhere around 30-50 KSI. This is going to be more like 100 KSI. A lot more tensile strength and a lot more yield, which allows the head to do what it has to do without cracking.”

At the same time No Limit is doing some of the block work mentioned, the shop is also milling and machining the cylinder head.

“We can get it pretty consistent with the CNC, but we can’t get the CNC to ever make the flow numbers that we can do by hand, so we do some hand porting at the end,” he says. “The heads go on the flow bench, probably anywhere from three to six times to be what they need to be. Then we go through all the finishing processes of putting the performance valve jobs on, getting springs on, etc.

“For a Pro Stock engine like this, we’re using a triple spring. Typically, we’re going to run somewhere between 300 and 400 lbs. of spring pressure, which somewhat depends on the pushrod length and boost pressure that we’re running. The rpms typically are going to be 6,000 or less. The valve size on the intake is another thing that we look at.”

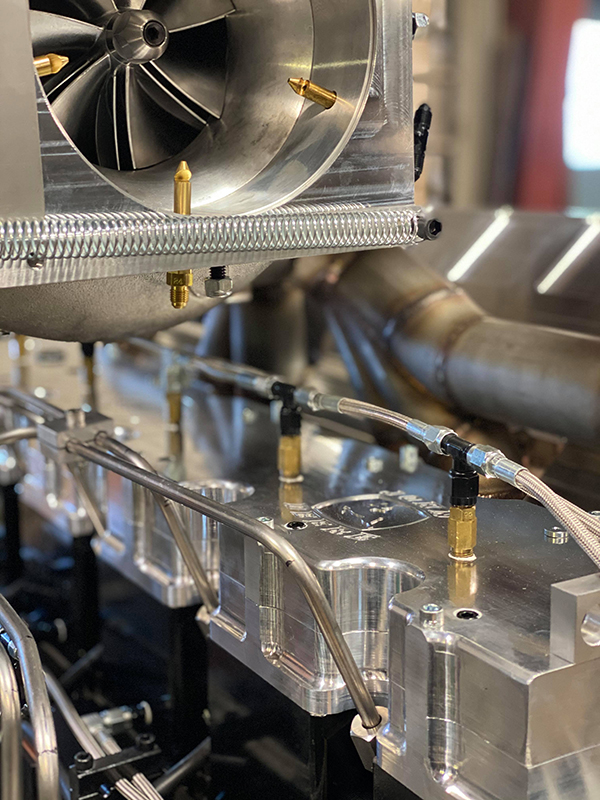

For this build, No Limit used Ferrea valves – titanium valves on the intake and Inconel on the exhaust side and titanium retainers. On a 2.375˝ intake valve, the cylinder head flows 500 cfm. The 2.05˝ exhaust valve will be within 12% of that. The rest of the valvetrain parts, like rocker arms and shaft stands, were all made in-house.

“On this engine, we have what we call a jumbo rocker that’s made out of aluminum,” he says. “It has a 3/4-inch roller on the roller tip and a 7/16ths stud on the ball end side. It’s a pretty massive rocker arm to take the beating that it takes as far as some of the exhaust pressures and things that we see when we’re trying to open the valve.”

Controlling all of those valvetrain parts is the camshaft, which as mentioned earlier, No Limit makes in-house. The camshaft on this engine is a tool steel camshaft.

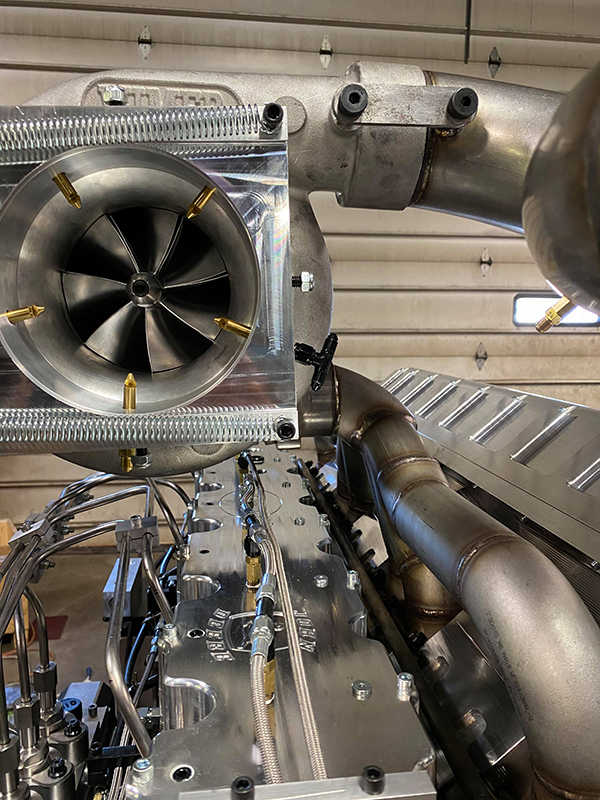

The turbo on the John Deere, which is mandated by the OTTPA Pro Stock rules, is a 5˝ Wimer turbo. No Limit is also running an 18mm Harts billet fuel pump and Harts injectors.

“The oiling system features an Aviaid pump, which is a five-section pump with three stages,” he says. “We have three engine oiling stages, one fuel stage and one turbo stage. The drive system on the front of the engine is all made in-house too. All the billet intake manifold and exhaust manifold fabrication we do through No Limit. The valve covers, the five-nozzle fogger and the water injection is all done in-house.”

Other parts of the 680 cid John Deere engine made by No Limit are the timing cover, billet timing gears and a stainless steel 10-gallon oil pan.

“These engines, as far as rpms, will run typically from 4,500-5,200 rpm when they’re pretty well loaded going down the track,” Staab says. “At the end of the track, they’ll drop down to about 3,800-4,000 rpm. That’ll depend on the sled setting. If it’s going to be a shorter track, you might see those rpms a little lower. If it’s a longer track, they might be a little bit higher as far as where they make power. A lot times, they make power between 3,800-4,500 rpm. That’s where their peak power is typically made.”

Engines like this 680 cid OTTPA Pro Stock John Deere typically have compression ratios from 10:1 up to 12.5:1. According to Eric, it depends on the size of the turbo, cubic inches, the cylinder head, and the camshaft. That will vary what the compression ratio is.

“This engine should be a little bit over 3,000 horsepower,” he says. “That’s what we’re shooting for with that 5˝ turbo. Torque-wise, we’re probably looking somewhere in the 4,500-4,800 lb.-ft. range.”

The finished engine is going in a John Deere tractor similar to what it would have been in originally, but with far more horsepower. Just the way we like it!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].