Diesel of the Week is presented by

As most of us do when we see something we think is cool, we want to know more about it and possibly get involved. When Ethan Patterson attended a truck pulling event to watch his cousin compete, he thought it was super cool, and it was the launching point of his interest in diesel trucks more than 15 years ago.

“In 2003-2004, we’d go down to the county fairs and watch him pull and I would ask him all kinds of questions,” Patterson says. “My first truck was a diesel. I had to have one and at that point I couldn’t afford to pay anybody to work on it, so I figured it out on my own and started tinkering on my ‘96 F-350 7.3L Powerstroke.”

It wasn’t long before Ethan’s passion for diesel work evolved into something bigger and all of Ethan’s buddies would ask if he could help them fix their trucks.

“I was pretty determined to do it on my own, so I figured things out through a fix, break and repeat process,” Patterson says of his early diesel days. “That turned into doing what we do now.”

Ethan had a full-time job working for Cargill, but he gave that up to chase his dreams of opening a diesel shop with his business partner and fellow truck puller, Colton Wilson. In 2010, they opened Wilson Patterson Diesel in Lafayette, IN. However, the amount of work they received was quickly overwhelming and the duo couldn’t manage it. After just one year, Colton returned to his family’s farm and Ethan also went back to agriculture, leaving diesel as a part-time gig.

“I did it for a year and it was too much,” Patterson admits. “We had so much business and I couldn’t keep up. I was 20 years old and I decided that I was going to take it back to a part-time gig and go back into agriculture.”

Farming became Ethan’s primary focus for the next four years, but diesel work was always there tugging at him to give it another try. After Ethan and his wife Lauren had a full-term still born son in 2015, they realized life was too short to give up on your dreams and both Ethan and Lauren jumped back into Wilson Patterson Diesel full-time.

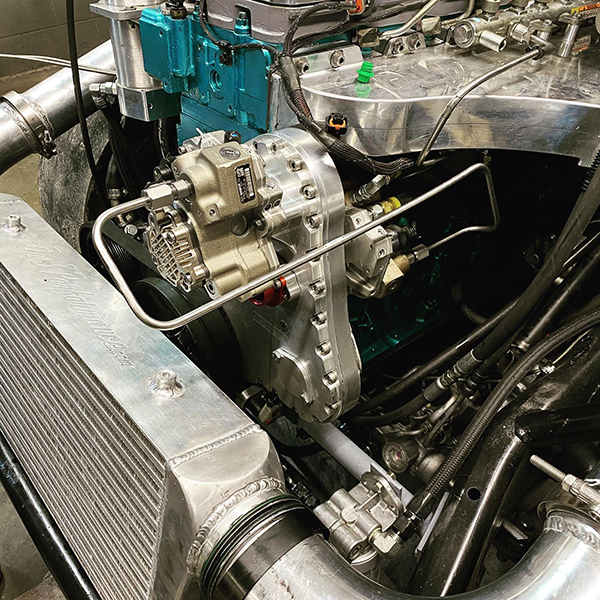

“We specialize in high-performance transmissions,” Patterson says. “We have a couple CNC machines and we do some engine building, but our main thing is building transmissions for heavy-duty towing and extreme applications. We make sure competitors have a transmission that can work through the abuse that they put them through.”

A majority of Wilson Patterson Diesel’s business is Dodge stuff, but the shop also does Allisons and Ford stuff too. Ethan says they’ll also get into gas drag racing applications as well, building Powerglides and Turbo 400s.

“We use our knowledge from breaking everything in the diesels to make an indestructible gas transmission,” he says. “We put them through absolute torture and know every limit of every part that you can imagine. When it goes into a gasser it’s freaking stout.”

Today, Ethan and Lauren run the shop along with some part-time help, as well as family and friends who stop by every now and then to lend a hand. While transmission work is the shop’s focus, they will take on a few diesel engine builds.

“Engine-wise, we can do some of the machine work ourselves, but the big machine work goes to Hunter Snyder at Pine Hill Diesel & Auto,” Patterson says. “For the transmission work, we’re pretty tooled up to do that work in-house.”

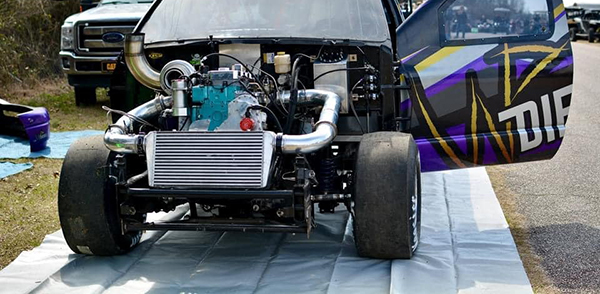

And speaking of Pine Hill Auto, one of Wilson Patterson Diesel’s more recent builds is Ethan’s own 2006 Ram 3500 with a 6.7L Cummins engine that Hunter Snyder helped build. The truck started as a customer’s project for the Ultimate Callout Challenge.

“Originally, we built this truck for a customer,” Patterson says. “We sponsored the chassis side of the truck for a customer in Massachusetts named Jason Lewis. It was for the UCC qualifier in 2018 with intentions of it being an ODSS Pro Street truck.

“We got it completed for the 2018 UCC qualifier and then he got out of drag racing and the chassis came back to us in late-2019/early 2020. It was basically a rolling chassis, so originally we had a sleeved down 6.7L with a 5.9L bore in it and our 48RE transmission that we built in-house. Recently, within the last three months, we put a Pine Hill Auto deck plate engine in it. Pine Hill Auto did all the machine work and assembled it.”

The new 6.7L Cummins engine features a 6.7L bore with a 5.9L crank, a Freedom Racing Engines cylinder head, D&J Precision pistons and rods, an Industrial Injection Gorilla girdle, 14mm head studs, and it is a dry, deck plate engine.

“It has a 5.9L crank because we wanted to have an rpm engine, not a torque monster,” he says. “Our intentions and what we do with the truck is we race No Prep events. We go and street race on slick surfaces and race what they call a backwards track. We’ll race from the shutdown towards the tree, which is super hard to get traction on. We set it up so it would take the torque curve out of it and not blow the tires off. We wanted horsepower that we can contain and not torque.”

The Cummins engine also has a single Stainless Diesel S485 turbo with three kits of nitrous. It has S&S 500% over injectors with two S&S 12mm CP3 pumps and a Waterman pump supplying the CP3s, as well as a Fuelab fuel pressure regulator.

Additional internal components for the Cummins build include the factory newer-style rocker arms, Manton valve springs, retainers and pushrods, and bigger valves from Freedom Racing Engines. Additional external components include an On3Performance 4˝ intercooler and CFT Fabrication did the intercooler piping and hood stacks.

The truck’s 48RE transmission utilizes Sonnax shafts and hard parts as well as Raybestos parts. And according to Patterson, the truck is back halved, so it has the factory frame rail from the front bumper mounting holes to about a foot behind the cab. From there on is the shop’s own back half that they made.

“The truck was originally a single cab dually,” he says. “We added the wishbone to the front differential, so we have front and rear wishbone on the truck. We also added an anti-roll bar on the front differential, rack and pinion steering and we switched to what they call a small tire – either a 29×10.5 Hoosier or a set of 28×10.5 Phoenix tires that we run – depending on what the class rules are.”

According to Ethan, this truck and engine setup doesn’t require too much maintenance because they’re not trying for a crazy fast 1/8th mile, nor are they pushing to 2,700 horsepower. Rather, they tune according to what surface they’ll be racing on.

“When that surface is really slick, a lot of times, you’re not using anywhere near the horsepower of what you would on a prepped surface,” he says. “Firepunk Diesel did some dyno tuning on this engine. We did all fuel numbers first, with no nitrous. The turbo and engine are built to have nitrous. It doesn’t really make impressive numbers on fuel only because of the way we have the turbos set up to have a ton of nitrous on the turbine side. It’s not super, super efficient on the compressor wheel.

“Our highest horsepower on fuel only was tune 4 and it made 1,310 horsepower. We added three kits to nitrous on tune 3 using two 2.136 jets and an .078 jet and made 1,895 horsepower and 2,063 ft.-lbs. of torque. It will break 2,000 horsepower – we just have to open up the wastegates to allow the excess pressure not to over-speed the turbo.

“Our tune 1 makes 1,200 horsepower on fuel only, and it can go up to 1,620 horsepower and 1,967 ft.-lbs. of torque on the three kits of nitrous as well. It’s super lean, but it runs really good. It runs really cool and smoke-free on tune 1 with the three kits of nitrous.”

Clearly, no matter how this 2006 Ram 3500 and it’s 6.7L Cummins are setup to race, it’s going to be a fun time.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].