Engine of the Week is presented by

If you’ve been following our content in recent years, you’ve likely noticed our partnership with Steve Morris of Steve Morris Engines in Muskegon, MI. Steve began filming his Steve Tech videos at the beginning of 2020, and we’ve been right there with him to help share his great content on our channels as well to allow more people to learn valuable things about building performance engines.

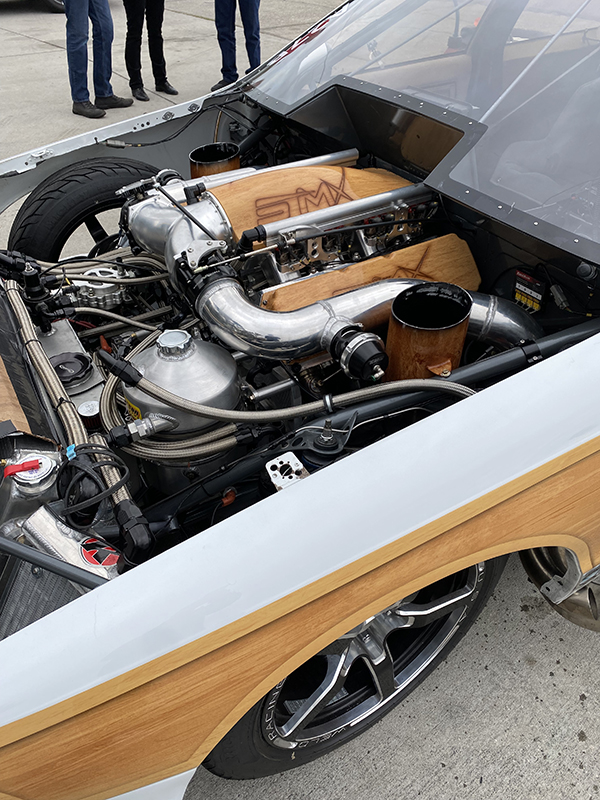

Steve’s shop is one of the best out there doing what they do, and it certainly shows in his rebuild of his 1993 Pro Mod wagon. Steve got his Boostmaster wagon back in running shape in order to compete at Sick Week – a drag-and-drive event across Florida that took place in early February 2022. We caught up with him throughout Sick Week and got the details of this awesome wagon and its 572 cid SMX engine featuring twin turbos!

“This should be Engine of the Year,” Morris quipped before telling us about the full build. “I’ve had this wagon a little over 20 years, and it started out as a street car. Racing has since taken over and it’s a continual money pit. You’re just throwing money at it and breaking stuff. It’s been 9 years since the last time I drove this car and that’s because we turned it into a Pro Modified car. It used to be a stock frame rail, drag radial with a ProCharger, and right now, because I have my own engine platform – the SMX – and I was already building this as a Pro Mod car, I thought it’d be really cool. The build just took so long due to chassis jail and paint prison and all the other problems that you have getting cars built.”

The wagon, as it is today, is a dual rail, full Pro Mod chassis. In fact, it’s the next serial number car from what Tom Bailey’s 2.0 is and was built by the same guy. According to Steve, it’s got a lot of cool stuff in it, and we can’t disagree with that.

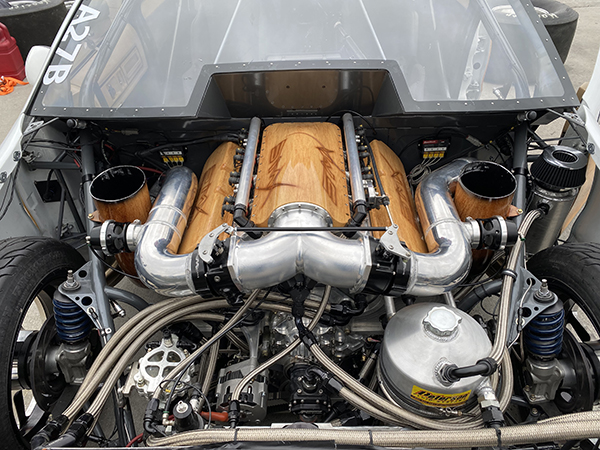

“It’s my SMX engine, which is capable of 4,500 horsepower,” he says. “This has twin 98mm turbos on it. The SMX platform is my block and my cylinder heads, so it’s fully water jacketed and all billet. It’s a maximum endurance engine, which means it’s not made for cooling down in between rounds, it’s made for driving hundreds of miles at a time in 100-degree heat. It does share some common architecture with Chevy, Hemi and Chrysler engines, but there’s some different things about it too. The main key is the billet block, billet cylinder heads and all the water jacketing that we have.”

Steve’s SMX setup will only work with an SMX block and SMX cylinder head. Due to a unique head-bolt pattern, you can’t use an SMX block and install different cylinder heads. The billet block features a 10.400” deck height, 4.840” bore spacing and a 4.500” bore. It has a Hemi front and a big block Chevy back.

Inside, the SMX features a Sonny Bryant 4.500” billet crank with Hemi journals and BBC mains that’s been fully counterweighted, lightened and gun-drilled. The pistons are from Diamond and feature Hemi-sized pins and Total Seal rings. The connecting rods are aluminum and come from MGP. Steve utilizes billet main caps and unique main studs that have a 5/8ths shouldered bottom and taper to a 1/2″ on top. The shoulder allows for easier location and more accurate centering.

The SMX engine has a 65mm cam tunnel and Steve uses a camshaft with four babbitt bearings. The cam helps run a very hefty valvetrain within the SMX heads, which includes .904 bearingless lifters, 1.500” diameter Pro Stock-style springs, and Manton 1-piece rocker arm stands and Manton rockers. The cylinder heads, which only fit on the SMX block, are no less than 3/4” thick at any part, and feature o-rings for both the intake and exhaust ports, water plates and SMX hoops.

The engine runs a Peterson dry sump oiling system and Steve has three injectors per cylinder to allow for different fuel for the street and the track.

“The car has two totally separate fuel systems,” Morris says. “There’s a fuel tank and fuel pump in the back that runs on pump gas and runs a third set of injectors that are underneath the intake manifold. On race mode, we run the mechanical pump thats in front off the camshaft on methanol, and that runs through a FuelTech system and FuelTech injectors on top.”

As for the potential to make 4,500 horsepower, Steve told us he’s not making that at Sick Week. Rather, after 9 years of the car not being in competition, he was happy to just be making passes.

“With everything being brand new, I was just happy to make passes and go down the track,” he says. “In fact, we started this up on the Friday before Sick Week, put it on the hub dyno and made one pull and said, ‘Ok, good enough, let’s go.’ We loaded up and took off for Bradenton, FL on the Saturday morning before the event. I hadn’t driven it [more than 50 feet], let alone doing anything else. [Monday] was the first drive. Outside of testing, Monday was the very first full pass. It went 6.82@215 mph.”

That time was the third fastest of Day 1 at Bradenton, and it put Steve in first place in the Unlimited Iron class. With his twin 98mm turbos, Steve was running them on 40-lbs. of boost. However, he does have tunes where 60-70-lbs. of boost is used.

“We’re way soft right now on it, since we’re just trying to get back to Bradenton,” he says.

Part of Steve’s journey to make it through Sick Week involved losing a cooling fan along the way. To help keep the engine cool, despite a large radiator, Steve had to get creative with a Budwieser beer cardboard box that served as an internal air dam to force air into the radiator instead of going over the top of it.

“As we were driving down the road, the engine temps just kept creeping up, creeping up, creeping up, creeping up, and I was like, ‘What the heck?’” he says. “I’ve got a 3-foot-wide radiator in this thing! I took the hood off and thought to put a little air dam in it and it knocks 40-degrees F off from just stupid cardboard. It’s some Drag Week engineering.”

After we left Steve in Orlando and went on to Gainesville, Steve managed another 6-second run – 6.896@215 mph. Unfortunately, after those two 6-second runs, Steve and his wagon ran into some transmission issues that greatly hampered the remaining two days. Those issues didn’t end Steve’s Sick Week, but it effectively took him out of any chance at the podium in the Unlimited Iron class.

Steve and his team managed to finish South Georgia Motorsports Park with an [email protected] mph and ended back at Bradenton Motorsports Park with a [email protected] mph. Just finishing events like these is half the battle, and if it wasn’t for transmission issues, Steve might have been hoisting some Sick Week hardware. Look for Steve to be competing at additional events this summer, and check out more of Steve’s great work on YouTube.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Engine & Performance Warehouse Inc./NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].