Diesel of the Week is presented by

For Daniel Hargrove, fixing trucks started out as a hobby and soon grew into a career. Hargrove owns a small shop in Charlotte, TN named D&C Automotive Repair where he provides general repair services and performance upgrades in the 500-1,000 horsepower range.

For the past few years, he’s been campaigning his ’06 Ram 2500 in the ODSS 7.70 class, but last year he had intentions of moving up to 6.70. The powerplant was initially sent to an engine shop for some upgrades, but after being unsatisfied with the result, Hargrove decided on a new builder. The new shop would be none other than LinCo Diesel Performance.

Jeff McCord and the LinCo team barely need an introduction, as their work speaks for itself. They were the winner of Engine Builder’s 2021 “America’s Best Diesel Shop,” a prestigious award that recognizes the best of the best in the performance engine building world.

McCord’s shop focuses primarily on Duramax and Cummins engine work for all kinds of applications, as well as transmission work, maintenance and repair work, and some parts manufacturing. Manufacturing parts, doing complete transmission work and keeping all engine and machine work in-house is easy since LinCo Diesel Performance has a brother company in LDP Machine, a full engine machine shop.

The 8,600 sq.-ft. machine shop stands right next to the 15,600 sq.-ft. building that houses LinCo Diesel Performance. Right now, the entire facility sits at 25,000 sq.-ft. on six and a half acres, with plenty of room to expand.

“I’ve known Jeff for a while just by seeing him at events over and over,” Hargrove says. “He really went above and beyond on this build and gave me super detailed notes of everything that was done to it – like every spec of the motor and every bearing that went into the engine in case I wanted to tear it apart myself later.”

Extreme power wasn’t the biggest concern in the beginning, as the truck was sitting a little under 1,000 horsepower to begin with and Hargrove wanted to maintain its streetability. Luckily, McCord and Hargrove found a solid middle ground in the end.

“We started off with a 6.7L block that now has ductile iron sleeves,” Hargrove says. “We ended up using a Hamilton 178/208 camshaft – we had a 188/220 but with the head and piston setup, that cam was going to be a little large and we would’ve had to take quite a bit off the pistons.”

Wagler rods connect the stock MAHLE coated pistons to the crankshaft and McCord had the entire rotating assembly from the crank to the flex plate balanced. Hargrove’s truck has one of the first engines to feature LinCo’s new dowel setup for the flex plates.

LinCo developed a specialized dowel kit and machined a Suncoast billet flex plate to accept it. With the flex plate doweled directly to the crank, bolts are less likely to come loose at high rpm as the flex plate can’t spin side to side.

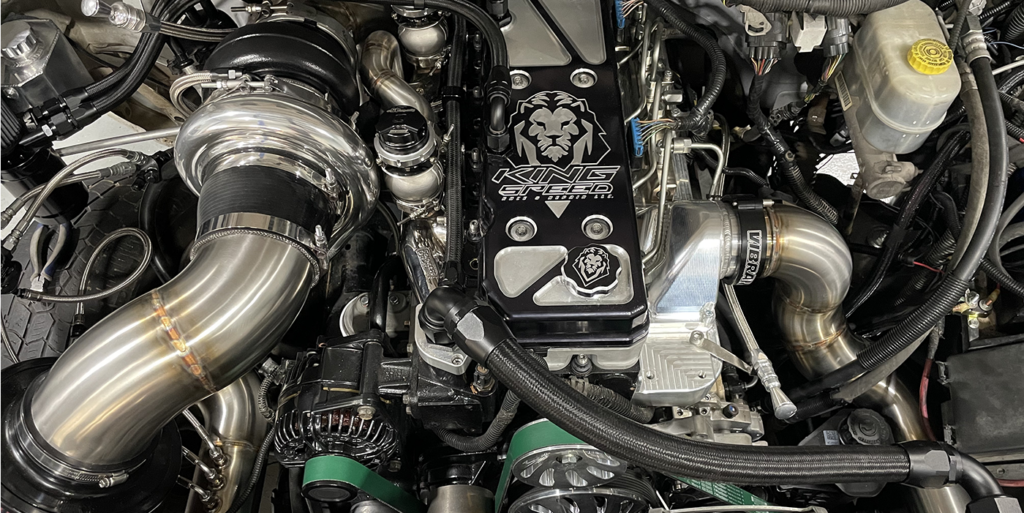

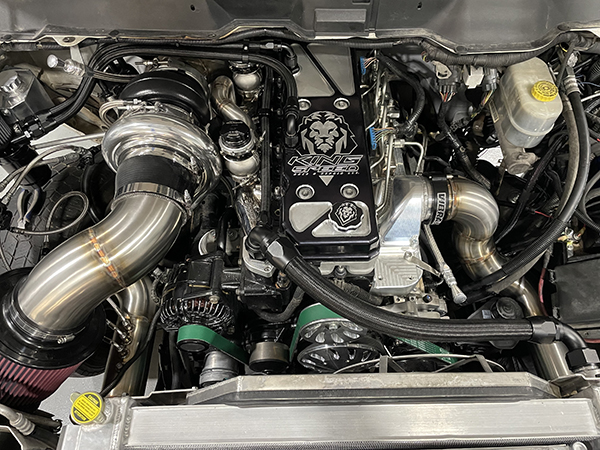

“Jeff went through and did all new bearings throughout the engine, and there’s seven cam bearings where the factory only has three,” he points out. “Wagler had already done the cylinder head and that’s got big valves, Wagler side draft with their dual spring setup. Of course, we used ARP bolts throughout and .625 head studs, then we have King Speed’s billet front cover.”

As for fueling, Hargrove’s system is powered completely by S&S Diesel Motorsport. A 14mm CP3 fuel pump that feeds 450% over 5.9L injectors, as the truck is a factory 5.9L with an 849 ECM.

On the air side, a Stainless Diesel polished T6 dual-gated competition manifold works in tandem with a single Stainless Diesel S485 96mm 1.32 housing Godfather series turbo. Hargrove also sprays the engine with nitrous, which was tuned by Logan Epling of Epling Motorsports.

“I use Nitrous Express’ Maximizer 5 with a Lightning 375 solenoid. I set it up for the truck to be able to run four kits because we were unsure if we were going to need a spool jet to get the turbo to light, but it does fine without it.

On fuel, the truck made 1,267 horsepower in a recent dyno pull, but the nitrous setup increased the power output greatly. On Hargrove’s personal best pull of 2,004 horsepower, the tune was set to see 80% throttle and above 20 lbs. of boost for the two .099 jets and .057 jet to kick in.

“It’s definitely aggressive on the street but it works well,” he says. “We have to figure out what we’re going to do with the suspension, and I’d like to get it painted because it’s still got factory paint, other than that it’s pretty much a finished build.

“I’d really like to thank Keaton Samples who did all of the fabrication work as far as the intercooler piping, downpipe, wastegate tubing, Logan Epling who handled the nitrous tuning, and Jeff McCord for the amazing engine work.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].