Necessity is the mother of all invention, and it certainly played a role in the founding of Choate Engineering Performance. The diesel engine and machine shop was founded by shop owner, Cass Choate, after finally becoming fed up with having to rely on others for certain aspects of his work.

“People began to bring me more and more vehicles and blown engines and I started using other machine shops locally,” Cass Choate says. “That was also frustrating because there was a no-fault-type mentality. There was no accountability for work and that led to a lot of frustration on my part. It all came to a head when I had a sleeve on an engine that had to go out. The machine shop installed a straight-wall sleeve incorrectly without leaving a step in the bottom of the block for the sleeve to sit on. It sucked the sleeve in the block and exploded the block within 30 seconds of me starting the engine up.

“At that point, I was ready to quit. I was done. I couldn’t do it anymore. I decided I was getting completely out of this business or I’m getting completely in it – one of the two. I chose the latter, and from there, I reached out to Ed Kiebler at Rottler, who has become a good friend, and I told him what I was trying to do. He thought I was crazy jumping in head first, but that’s how it needed to happen – ready, fire, aim.”

Cass started Choate Engineering Performance in 2013 and has been going strong for almost a decade. Choate started out in Whiteville, TN in a 7,500 sq.-ft. space and saw immediate growth.

“The shop grew from there, and because we were doing all our own machine work, more and more people asked me if I would build engines and ship them around the country, so that started to grow as well,” Choate says. “Then, I realized there was a big need for parts in this industry that would fix the problems from the OE, so we started to develop some of our own parts.”

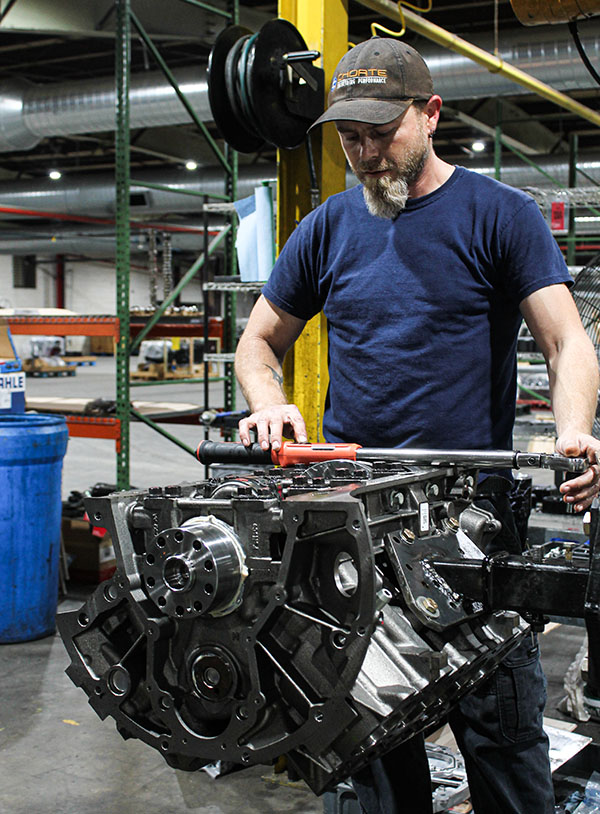

Choate Engineering Performance is made up of three segments – repair, engine building and part manufacturing. Almost two years ago, the shop had gotten to a point where more space was needed if more growth was going to occur, so Cass decided to make a big move.

“A little over a year and a half ago, we were running out of room and stepping on one another,” he says. “We were at 7,500 square feet and recently moved into a 155,000 square-foot facility.

We moved to the town over in Bolivar, TN. It’s funny because the local folks hardly know we are here. A majority of our work comes from out of state. We get engines and trucks shipped to us from Washington, Florida, New York, California, etc.”

Choate Engineering Performance began by working heavily on the Powerstroke platform, and built up a reputation for that work, despite it only being a portion of what the shop could do. It wasn’t long before the shop also became known for its Cummins and Duramax work as well.

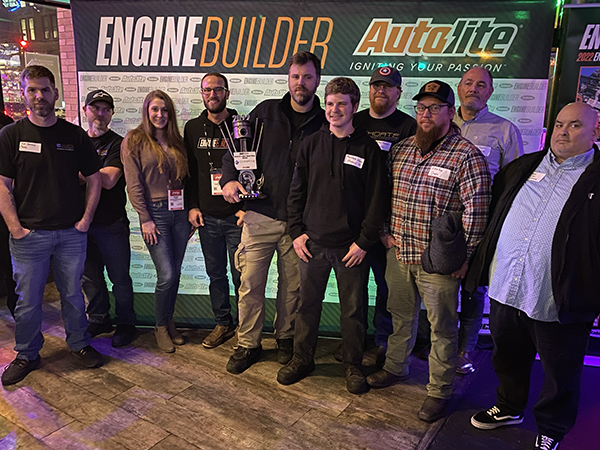

The shop’s dedication to quality engine work, its growth, its machining capabilities and its impact in the diesel industry, all make Choate Engineering Performance well deserving of Engine Builder’s and Autolite’s 2022 America’s Best Diesel Engine Shop award.

The shop has 30+ employees who help to ensure all work is done in-house to a very high standard.

“We grind our own cranks. We have horizontal and vertical mills, five-axis CNC capabilities, cylinder head porting – pretty much everything,” he says. “The shop does general repair as well as high performance work. Our motto on our website and on our t-shirts is ‘Stock is Not an Option.’ We don’t actually build a “stock” engine. Our Model C, which is a play on the Model T name, is the bare bones, no thrills or frills engine package, but it does fix all of the OE problems. We will not build an engine back to OE with OE parts if there’s a known failure – those issues are addressed. We also have three other platforms that are upgraded in different various manners.”

As for Choate’s early reputation for Powerstroke work, Cass says it’s funny how that naturally came to be.

“We started with Powerstrokes, but we have worked on the other diesels this whole time as well,” he says. “How it started was people would come by the shop and see a whole row of Fords and they’d think that was all I worked on. I got to the point where I would take the Fords and park them in the back where nobody could see and start parking the Dodges and the Chevrolets up front.

“It wasn’t that having a reputation for Ford was bad, it’s just that there was much more that we did and people didn’t know it, so I would rotate the trucks. Today, we definitely do a lot of Cummins and Duramax stuff in addition to Powerstroke.”

While Cass and his team have done an excellent job making quality work a priority and the engine building side has become renown across the country, he says it’s the work within the business itself that has his focus going forward.

“Most people in this business can build a great engine and send it out the door,” he points out. “What I want our company to be known for is the process. I want our process to be ironclad from the point of contact with a customer to the point of pickup or ship out. I want our process so streamlined that repeatability is just ingrained. That’s something I think a lot of people don’t focus on.

“The thing that excites me the most is the process and getting it extremely streamlined. We’re talking 5S, lean manufacturing and those kinds of things, which allow you to do more. I want Choate Engineering Performance to be akin to Chick-Fil-A – you know what to expect every time. Everybody thinks about a product, but not the repeatability to be able to create that, and that’s 100 percent process. That’s my mindset and the way that I want to create – it’s one stone upon another. Are you really trying to build a product, or are you trying to build a business? There’s a difference.”

It’s been that kind of drive and attention to what’s important that make Choate Engineering Performance very worthy of our America’s Best Diesel Engine Shop award.

“An award like this builds morale for the shop,” Choate says. “It’s very flattering and complimentary and encouraging. We’re out here in podunk Tennessee, and for anybody to know who I am just astounds me. That’s beyond my wildest dreams. When I started this, I just wanted to make a living for my family and provide something, but to be recognized among peers and those who are well above you in the industry is very encouraging and it’s very provoking to do better.

“For the guys in the shop too, it’s a win for everybody. Ultimately, seeing some of the fruits of their labor is encouraging. It means a lot to everybody here at the shop to know that it’s not just Bolivar, TN – this is nationwide and worldwide. You’re on a much bigger stage than what you ever anticipated.”

Be sure to check out Choate Engineering Performance online and on social media to see all the reasons they’re our 2022 America’s Best Diesel Engine Shop. EB