Cylinder head work can often be divisive. Some love it and some hate it, but it’s absolutely necessary for peak performance. Both Luke Wilson and Josh Klein gravitated towards cylinder head work as they each grew up in engine shops. They’d spend hours honing their skills with a grinder and a flow bench, which would eventually turn into their business, 4 Piston Racing in Danville, IN – today one of the leading Honda cylinder head and engine shops, not just in the U.S., but globally.

“Josh and I started in this business because in the late-‘90s we wanted to race and we couldn’t afford to race,” says Luke Wilson, 4 Piston Racing co-owner. “We did everything we could to try to come up with ways to make money so we could go race with the guys we looked up to. In doing that, we had to be pretty resourceful and we were buying engine parts and really just weren’t happy with some of the stuff we got.

“We grew up in engine shops and we had some good mentors. We got attached to cylinder head development. It was the first thing those engine shops really allowed us to do after hours was sit there and play with a flow bench and a grinder. That’s where we started – just playing with cylinder heads.”

Around 2000, Luke was trying to push the shop he worked for into CNC head porting, because the amount of hours you had to put into a really good, race-developed cylinder head was so much that you couldn’t charge for it. The shop owner didn’t see it that way, and CNC was a path Luke knew he needed to take on his own.

“He couldn’t imagine paying somebody for machine time when you can sit there and get paid to do it yourself,” Wilson says. “We kind of went our separate way at that point.”

Both Luke and Josh had been doing engine and cylinder head work on the side out of a home garage, and in 2000, they partnered 50/50 on a new business called 4 Piston Cylinder Heads, which today is 4 Piston Racing.

“We just decided this is the path we’re going to go down,” he says. “We’re not doing this by hand. We can’t make money this way. We started it when we were kids and we haven’t argued yet. We partnered with Weld Tech and it’s all history from there. I remember, they thought we were going to do three or four heads or something. I remember when I did my 100th head, they were like, ‘I think we need to take this more seriously than what we thought.’ Then, when we got to 1,000, it just all changed. Everything just snowballed.”

The duo was literally building engines and porting heads in the garage of Josh’s house. They had no building, but set up the garage with the equipment they could afford and pieced it together.

“There’d be times we were trying to take a picture of a really, really nice engine and we had to hold cardboard up in front of a dog food container, so somebody didn’t see that we were in the garage of someone’s house,” Wilson laughs. “Eventually, we moved up to a shop and then we got a bigger shop and then we built our own place. We own the property and we own the buildings.”

The property in Danville, IN houses two buildings – one is 12,000 sq.-ft. and the other is 2,500 sq.-ft. The success 4 Piston Racing found, according to Luke, happened because the Honda market needed a motorsports grade engine builder, not just a tuner shop.

Inside 4 Piston Racing today, you’ll find a Newen single-point CNC cutter for seat and guide work, as well as a Serdi 100 for certain tasks. You’ll also find five CNC machines, both older and newer, including some Centroid 5-axis CNCs the shop recently got. There is also both a Super Flow water brake engine dyno and a Dynojet chassis dyno.

The shop is very heavily focused on Honda cylinder heads and engine work to the tune of 300+ engines and 1,000 cylinder heads annually!

“We didn’t want to build engines,” Wilson says. “We love engines and it’s necessary for development of heads, but we just wanted to do heads. However, we found there was a hole in the market. I hired an additional engine builder and then another and it just snowballed. It was a struggle to figure out how to make money at it. It’s really something we’ve been working hard on for 10 years to figure the engine building thing out, and I feel like we’re in a really, really good spot right now. At our shop, everybody has a motorsports background. I have a good crew right now, and that makes all the difference in the world.”

The engine builders at 4 Piston Racing have experience in IndyCar, Sprint Car, Top Fuel and other disciplines. All the engines and cylinder heads built are primarily for road race, endurance and drag race applications, and 99% of it is Honda.

“We played a little bit with other engine platforms, but we’ve since strayed away from it because there’s enough Honda work to keep us fed,” Wilson points out. “We’re even limiting the Honda platforms that we focus on because some of the stuff is out of production and just hard to get parts for, and they’re going to go away. We cover five different Honda engine platforms.”

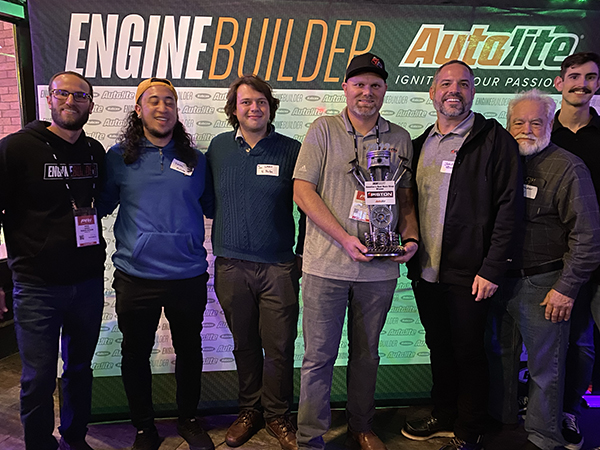

Due to 4 Piston Racing’s devotion to quality workmanship, it’s stature in the Honda segment, success on the track, and how 4 Piston Racing markets itself in the industry, we’re proud to name them Engine Builder’s and Autolite’s 2022 America’s Best Race Engine Shop. Over 20-plus years, 4 Piston Racing has showcased that it is more than capable of winning both on and off the track.

“It’s hard for me to even imagine what an award like this means,” Wilson says. “I still walk into a room of engine builders and other people in the industry who we’re afraid to talk to. We still look up to everything they do. Some of these people have shops a quarter of the size of ours and I just want to pick their brain. I want to learn every day. I don’t think it’s really hit us how fortunate we’ve been. This recognition is a huge honor. I still feel like we’re so close to the two guys in the garage building engines, and it hasn’t really set in yet how things are. Every once in a while, we get to reflect on it, and this is something that means a lot.

“I still feel like we’re the little guy and I always want to feel like the little guy because that’s what drives us to push harder and to try to be better. I have aspirations to be like Ilmor Engines. This recognition is something that means a lot, I can tell you that.”

The future of 4 Piston Racing obviously means a ton to Luke and Josh too, and that’s a big reason one of their initiatives moving forward is increasing the shop’s own part manufacturing.

“We manufacture a lot of our own parts now and we’re going to continue down that path because of the supply chain issues and the cost,” he says. “If we have the power to do it ourselves, we’ve been doing it. That’s a challenge because it’s more machines and more people and more space, but for certain parts it’s worth it.”

The team at 4 Piston Racing has been among the shops setting the bar in the engine building industry for over two decades, and they aren’t stopping now. Check out 4 Piston Racing online and across social media to see why they are deserving of our 2022 America’s Best Race Engine Shop honor. EB