Imagine founding and growing a successful engine shop that supports high-level race teams and manufactures high-quality billet components, and then deciding to move that business to the other side of the world. That task is extremely daunting in and of itself, but then imagine that because you’re now in a new country, your entire business history prior to the move doesn’t matter in the eyes of banks, so you can’t secure loans.

This was the exact scenario Noonan Race Engineering found itself in when the engine shop made the move from Australia to the U.S. in 2017. Finding a new home in Spartanburg, SC, owners, and husband and wife, Jamie and Renee Noonan, had to work hard to re-establish their shop here in the States. Despite the effort it would take, the couple excels at hard work.

“When we got to the USA, we didn’t know that all of our business history in Australia meant zero in America, so we couldn’t borrow any money,” says Renee Noonan.

“We couldn’t even get a $2,000 credit card,” Jamie Noonan quips. “We had to give them $2,000 to give us a $2,000 credit card. It was like coming straight out of school and your credit rating is zero.”

“We had to work really hard and our family sacrificed a lot to be able to put money away to get us where we need to get to,” Renee says. Where the engine and component business is today is quite remarkable, but more on that in a minute.

First, we can’t get to present day without looking at where Jamie and Renee have come. Jamie’s background has been racing, pretty much his entire life, thanks to a father who raced Top Alcohol dragsters in Australia. Jamie was just 10 when his dad began to race, and by the age of 14, Jamie was building his dad’s engines. However, after just three years, Jamie’s dad decided to quit racing, leaving Jamie to find a “normal” job driving forklifts and trucks. Jamie’s racing hiatus didn’t last very long though.

“A job opportunity came up with a V8 Supercar team in Australia, which is our biggest motorsport series – similar to NASCAR,” he says. “The opportunity was to be an engine builder’s assistant for Stone Brothers Racing, which was a Ford-backed team. It was 1995, and I was 19 years old. I was just an engine builder assistant for probably two months, and then the main engine guy quit and went to work for another team, so they were trying to find a replacement for him. They couldn’t find a replacement, so I stood in that position for a full season. They did really well that season and I maintained that position for the next eight years for that team. In that span we won four championships.”

In fact, the engine program Jamie led got so good that other Ford teams wanted to get engines supplied from Stone Brothers Racing. The shop ended up taking on another six cars to supply engines to, and they built a whole brand-new facility, which Jamie was in full control over.

“I got to decide what dynos we we’re going to buy, what spintrons and chassis dynos and the full layout of the shop,” he says. “I was in full control over engine development for the next four years.”

When the rules for V8 Supercar changed and got strict on components and weight, it made Jamie lose interest. In 2005, he left Stone Brothers Racing for a GM team, a Holden team, thinking a different engine would allow him to start his development program again.

“I was the new kid on the block again, and they already had their engine builders, so they didn’t want change, but I wanted change to step their engine program up,” Jamie says. “In the first six months, we clashed heads, so I had a discussion with the team owner and said, ‘Look, the only way this is going to work is if we let your people go that have been here for 15 years, and I’ll bring my people in and I’ll start my own business and you’ll get engines supplied by me.’ The owner agreed on it and he sacked the guys the next day. I was in full control. I was with that team for two years, and then we built a brand-new engine shop ourselves, and took on another Holden team with three cars. It just kept going forward with V8 Supercar engine programs.”

With the new engine shop, and the demand on engine development, Jamie needed his own CNC machine shop to do as much stuff in-house as possible.

“We had to hone our own blocks. We had to do our own valve jobs. We did all our own R&D. We had our own spintrons and two dynos. We had all this equipment just to service the V8 Supercar contracts we had,” Jamie points out.

With these new capabilities, and the uncertainty of how the Supercar series would keep evolving and what more rules might change, Noonan decided to go back to his roots and manufacture drag race components. Noonan Race Engineering was born. Jamie started the business in 2007 with his dad and another business partner.

“We started off manufacturing cylinder heads – the billet X1 cylinder head at that point,” he says. “We flooded the market in Australia because everyone wanted to buy Australian that was drag racing in Australia. We had really good success with all the Australian drag races, but we also sold to the European and U.S. markets.”

It was around this point, in 2013, that Renee entered the business. Jamie and Renee bought out Jamie’s dad and the other business partner and got to work moving Noonan Race Engineering to the next level.

“We started making valve covers and manifolds, and to really step up the program, we needed to manufacture our own block to house our own cylinder head design that we wanted to do,” Jamie says. “We didn’t want to change the head stud locations and rely on another block manufacturer to supply us with our custom blocks, so we decided to take on the block program and manufacture our own blocks. It really was a big task doing that. There was a lot of R&D involved in it and programming and trial and error as far as how much material you move at what point.”

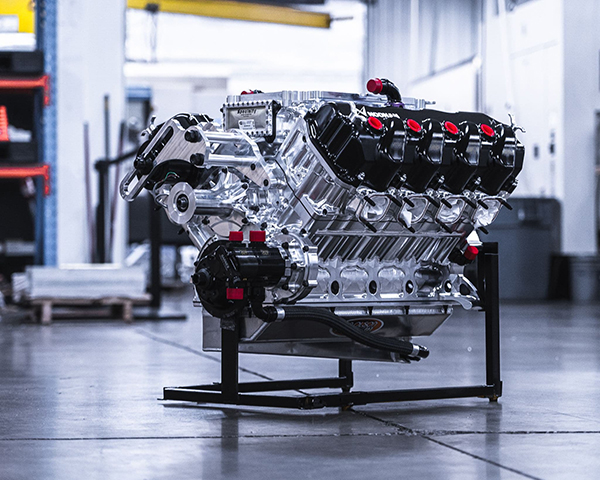

That hard work paid off and Noonan came up with its 4.8 bore space Hemi engine program, which was a custom Noonan block, cylinder heads, manifold, and valve covers.

“We had an alcohol dragster, so our goal at that point was just to make our own block to have a full Noonan engine running in that alcohol dragster,” Renee says. “From there, the knowledge that we learned from the engine block manufacturing process, we then went and turned that into an LS platform. We snowballed several platforms so that our same fixturing and tooling could accommodate variations of new product, but the same knowledge was used to develop them. We had the 4.8 engine program, the LS engine program, and then we did the water-jacketed engine program all within a 12 to 18-month period.

“It was at that point that Jamie and I traveled over here to the U.S. a lot. In Pro Mod, the rules showed that the best combination was a 4.9 [bore space] Hemi. That was the max. We came home from that trip and we wanted to capture the majority of that market space. That’s how the 4.9 evolution came about. Pro Mod racers were our biggest customers, so we wanted to give them something that we could continue to develop for a long period of time, and it couldn’t be easily copied or replicated by any competitor. Now, we spend most of our development on the 4.9 program.”

With the continued development of those engine platforms came another big change – the initial move to the U.S. in 2016. Noonan decided to start manufacturing all the blocks in the U.S. and keep all the cylinder heads and manifolds running in Australia. To do that, Jamie spent the next year in Spartanburg, SC while Renee led the Australian shop.

“We had two shops, and the time zone difference meant when the Australian shop was getting there at 7am, the U.S. shop was leaving at 5pm,” Jamie points out. “There was no really crossover time for corresponding with what’s happening, so it got a little hard to manage all that.”

In 2017, Jamie and Renee decided to shut the Australian shop down and move everything to Noonan Race Engineering’s new home in Spartanburg, SC. As mentioned, the move to the U.S. was tough on the business and tough on the Noonans themselves. Jamie’s love of engine development had to go on hold as the business needed to focus on manufacturing components to re-establish itself here in the States.

“When we moved, we had dynos and spintrons and all our engine test equipment in Australia, which we boxed in a container and shipped over here,” Jamie says. “We had this equipment just stored in a container because we didn’t want to set that up in the manufacturing facility. Because of that, the engine side of things had to be put on hold.”

Just two years ago, Noonan was able to purchase a couple more machines that helped streamline the entire manufacturing process. Today, Noonan Race Engineering has nine total CNCs – predominantly 5-axis Mazak machines – among several others.

“At that point in time, I was comfortable that the production output was so much easier than we had ever done it before that it was time to get some new product to keep growing,” Renee says.

To help with that growth, Noonan planned to add space for an Engine Technology Facility, so Jamie could continue his engine development and separate the manufacturing side of the business from the engine side.

“Our original plan was to put a shed up out back of the manufacturing space to double the size of that facility and set all the engine shop up over there,” she says. “Just as we had the contractor out and we were about to pull the trigger and hit go on that, we learned that the neighbor was selling the property next door. We were fortunate enough to be able to purchase that place. It’s worked out great for many reasons.

“Jamie was able to come over here and deck out the shop how he wanted to without space constraints. We can continue to grow manufacturing and have the space to build out the engine technology facility. Along with that, because that shop is standalone, we’re able to get our ISO accreditation and the engine shop doesn’t impact that accreditation because it’s in a different facility. It worked out well.”

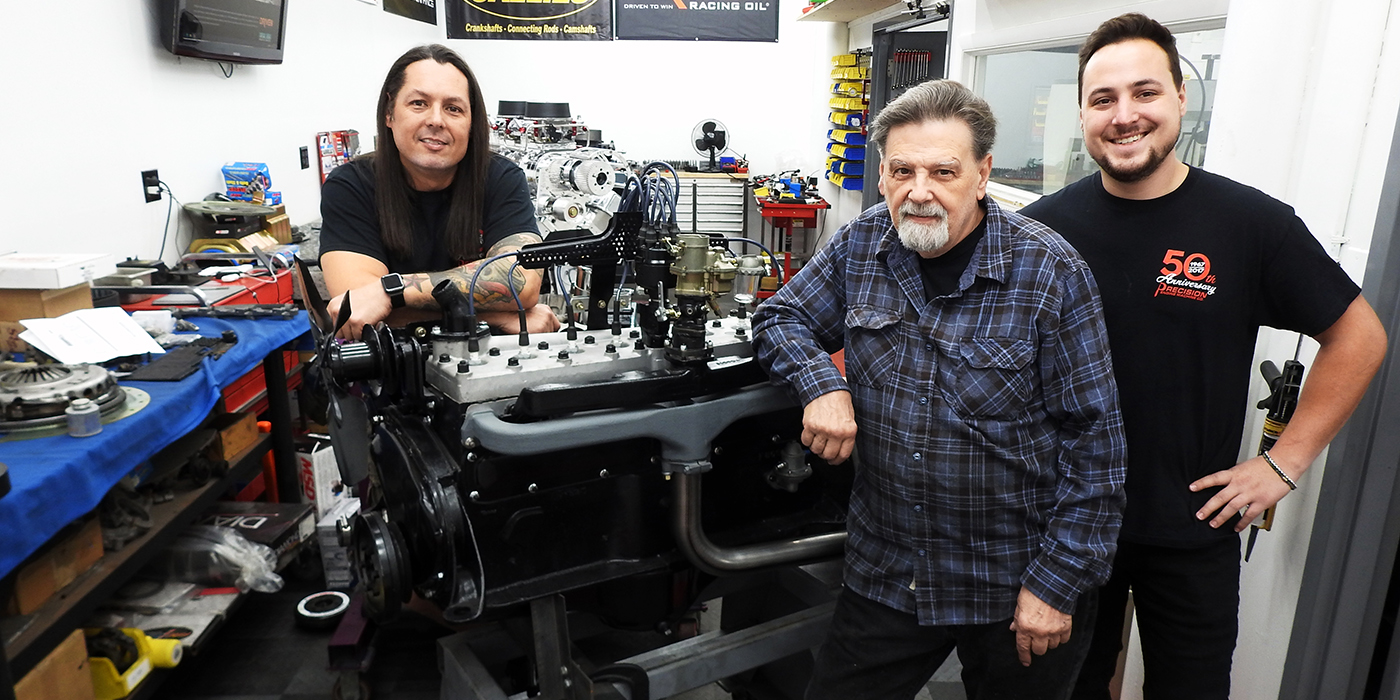

Today, Noonan Race Engineering sits on 6.5 acres and has an 18,000 sq.-ft. manufacturing shop and a 16,000 sq.-ft. engine development shop, both of which are absolutely stunning. The shop employs 13 full-time people, but the Noonans say they’re always looking for additional good help.

Seeing how far Noonan Race Engineering has come, it’s funny to think Jamie and Renee initially never planned to get into engine building, but the market had other ideas.

“Originally, we didn’t want to actually build engines,” Jamie says. “We just wanted to manufacture components and sell them to engine builders. But, there was more and more demand for us to build a complete engine because customers found it much easier. The increase in demand pushed us toward building this engine shop and R&D shop.”

“A lot of people saw our machining and how good it looked and how well our products performed, so we’ve started getting a lot of high caliber clients wanting the Lamborghini and the Porsche and the Honda and so on and so forth,” Renee points out. “Those products were initiated by wealthy clients, but the development then allowed us to sell those as a Noonan product. The evolution just continues. Those sorts of projects aren’t as big a market space as what the Pro Mod stuff is, but it’s for a boutique clientele that we’re fortunate to have.”

While those “boutique” engine projects are just beginning to get off the ground and grow, Noonan Race Engineering has truly become a go-to shop for the likes of numerous drag racing applications such as Top Alcohol, Funny Car, Top Dragster and Pro Mod. The shop produces about 150 engines a year. About 50% of those are 4.9 Hemis. About 25% are LS engines and the balance would be 4.8 Hemis and water-jacketed Hemis. Every complete engine and every billet component is absolutely top-notch quality, done to the highest standards, and is among the most beautiful, and well-performing, engine parts you can find.

For all these reasons, Noonan Race Engineering has been named Engine Builder’s 2023 America’s Best Race Engine Shop.

“It’s definitely a great honor for me,” Jamie says. “I really appreciate you considering us and actually giving us that award. It means so much to me to be quite honest. The journey that we’ve come on from the other side of the world to here, it’s an honor to take this award.”

“We’re a mom and dad who have probably done it the hardest out of the majority of big business over here,” Renee says. “Our families and our kids and everything they’ve sacrificed as well. To be renowned in the USA as the best. That’s pretty badass.”

Barry Pettit, Noonan’s sales and manufacturing supervisor, says he’s never met two people who work as hard as Jamie and Renee.

“People walk into this shop and just say, ‘Wow!’” Pettit explains. “The guys in the shop get to see that every day from these two as far as leadership. This shop is just an example of how they perform every day. This level is the norm for these two. That’s what’s amazing. They’re used to breaking records. They’re used to setting industry standards. It’s incredible to see every day.” Looking toward the future, Jamie and Renee hint that more components will be added to the list of what’s manufactured in-house at Noonan, and a new engine is also being developed that is sure to impress for 2024! EB