Engine of the Week is presented by

No one enjoys seeing a beloved, long-standing company go out of business, especially in an industry such as ours where passion for performance and racing runs deep. When the recession hit in 2008, much of our industry struggled to get back on its feet. Esslinger Engineering was an engine and machine shop that struggled even more than most.

Focused on Ford performance engine work and located in Chino, CA, Esslinger Engineering had one customer in particular come to its rescue. A customer of the shop by the name of Bill Buckley found out Esslinger was in trouble and didn’t want to see a shop he did a lot of business with disappear, so he bought it.

Buckley is not only a diehard racer from New Zealand, but he also owns Buckley Systems Limited, a leading supplier of precision electromagnets, as well as a couple race tracks and a race team. He invested his own money to get Esslinger Engineering back on the right foot.

“He didn’t want to see Esslinger go down, so he bought it to keep it going,” says Esslinger’s VP Kasey Slemmon. “He invested some money into it. We got some new tooling. He got us out of debt and dialed in and we restructured. That’s when I actually took the helm. Bill is president over in New Zealand and I’m vice president. I took over operations and reorganized the company. Since then, it’s been a progression of fighting every day to make it a better place, and we have.”

Esslinger Engineering has been around since 1968, owned by the Esslinger family for 44 years until Buckley bought it in 2012. Despite an ownership change, Dan Esslinger stills works at the shop a couple days a week. Kasey Slemmon found an opportunity with the shop because of his background as a machinist. In fact, he worked for a company that counted Esslinger as a customer.

“They hired me in 1999,” Slemmon says. “I made stroker cast crankshafts on a conventional mill and lathe. That’s where it all started here for me and everything has progressed from there. Since the reorganization, I’ve diversified the company quite a bit. We mainly did 2.3L Ford Lima engines. That’s a more than 50-year-old engine now, so it’s slowly died off. We still sell a lot of parts for those, believe it or not, but it’s not like it used to be by any means. We’ve been tapping into the later Ford engines such as the Duratec and EcoBoost. We’ve been doing that for about the last six years. That’s probably at least 60% of our work.”

Another aspect of the shop’s engine work is a billet Midget engine for Midget racing that Slemmon says is only a small part of the shop’s overall business, but something that is designed from scratch and built entirely in-house.

“We manufacture it all ourselves,” he says. “We’ve had some really good results. Every engine builder’s dream is to design it, make it and run it. It doesn’t get better than that when you’re an engine builder.”

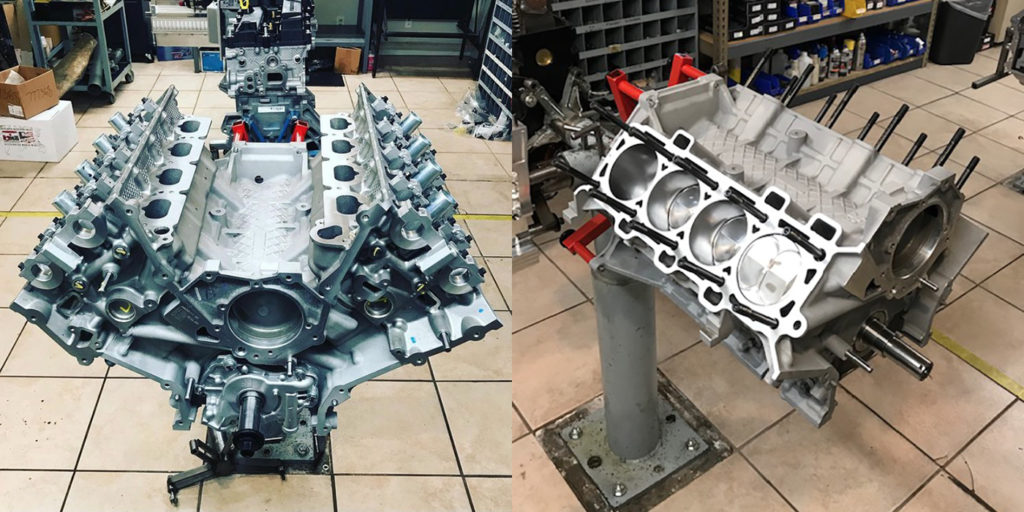

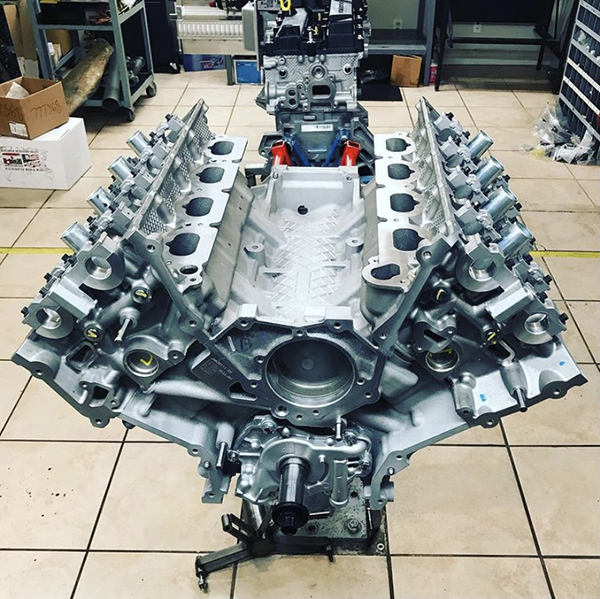

In total, Esslinger’s engines are used in a number of different racing applications, and it’s not just here in the United States, it’s all over the world. Something else Esslinger Engineering has just started to get underway is an engine program for the 5.0L Ford Coyote engine.

“What we do is we look at anything that would break, and if it’s something that would break on a stock engine, you reinvent it and reverse engineer it to make it better,” Slemmon says. “I won’t sell anything that’s not reliable. If you’re going to put an engine through more extreme circumstances, reliability is the first thing you do, even before power. From there, you look at areas where you can get performance gains out of it. A lot of that comes from porting the head and making camshafts and that kind of stuff.

“I get all the 3D computer models of the cylinder heads from Ford and I run simulations through them and manipulate the ports to get them to flow better. We put them on the flow bench and then put them on the dyno. We’re already starting to rebuild some of these Coyote engines.”

With eight full-time employees, a few part-timers and the capability to do all machine work in-house within its 7,500 sq.-ft. shop, Esslinger Engineering is well positioned to churn out a better 5.0L Coyote.

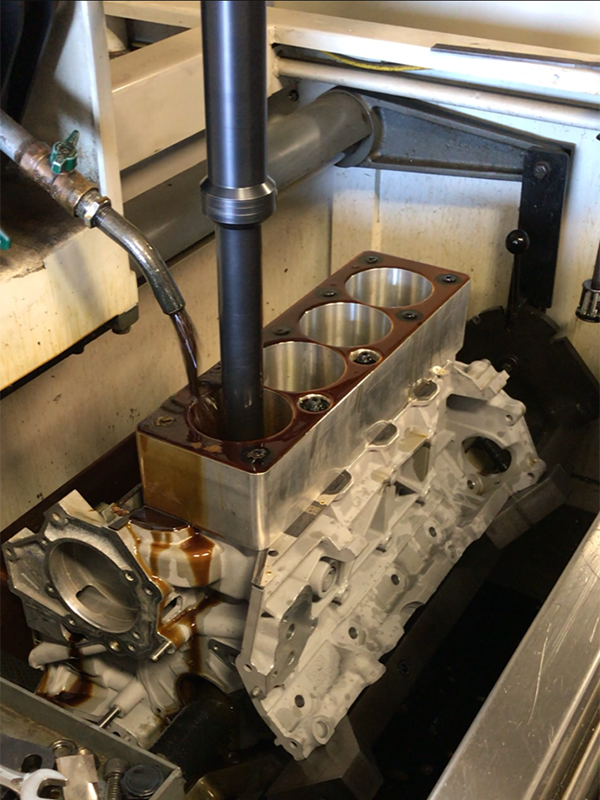

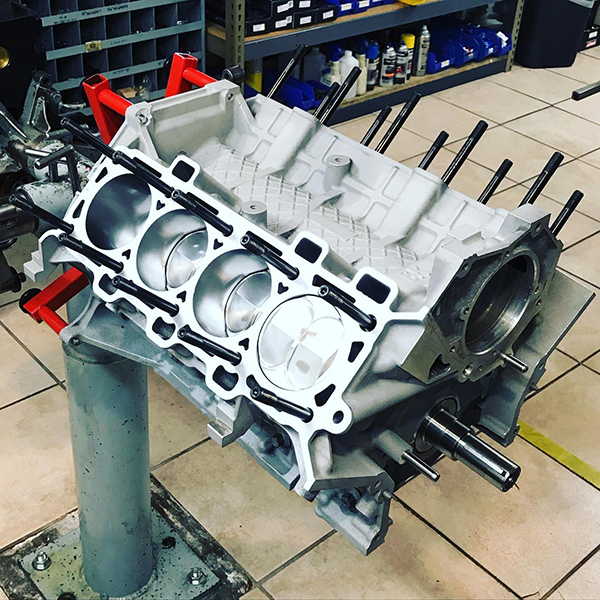

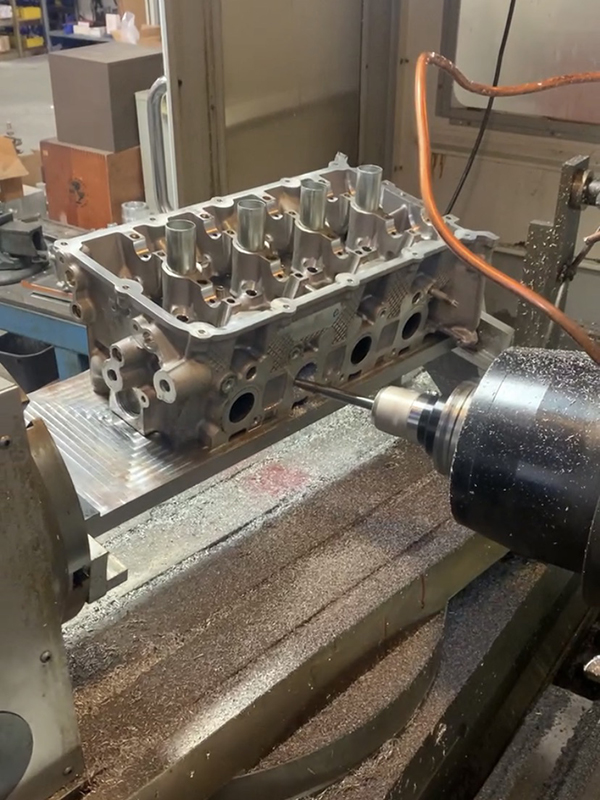

“What we’re doing right now is we’re putting sleeves in them, so we can go to a bigger bore and make more power without having to worry about cracking the OEM sleeves,” he says. “We’re doing that all in-house. We bore and stroke these engines from a stock 302 cid to 347 cid. We also port the heads and do a high-flow valve job, which creates a major difference from factory to gain performance.”

According to Slemmon, the shop was also able to find a lot of power in the Coyote engine by the way Esslinger hones the cylinders.

“Everything we do here that we hone, we actually put a surface tester on it and check the RA values,” he says. “We got that dialed in to where we can get the rings to seal really nice. We torque plate hone them, so we have the capability of honing them at 200-degrees as well, which we’ve seen some really good results with.

“We’re also in the process of making a few different cam grinds for them. We’re trying to do the same thing that we did with the 2.5L Duratec market. We’re going to somewhat mimic that by having anywhere from performance sport builds up to the baddest thing out there.”

Esslinger plans to have several different stock replacement cams for customers to choose from depending on whether they want more bottom end or top end power. The cylinder heads will also have two or three different port options depending on what customers are using the engine for.

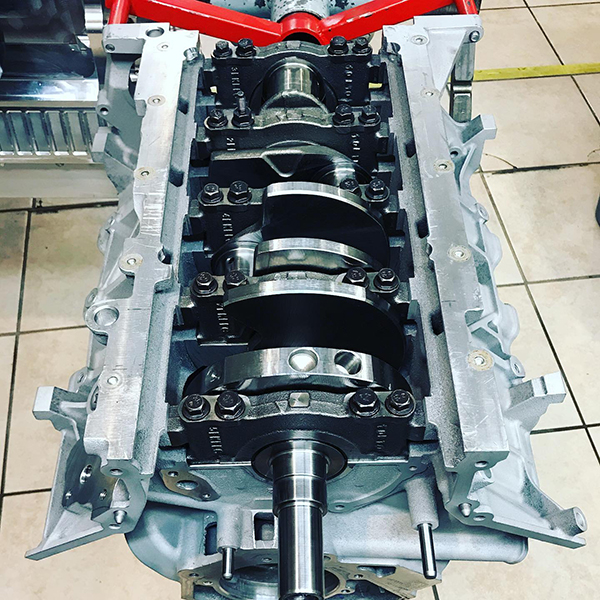

From there, Esslinger’s 5.0L Coyote gets outfitted with a set of high compression forged pistons, spec’d in-house and made by either JE Pistons or RaceTec Pistons, a good set of rings, custom-made connecting rods, and deeper valve depths, so customers can run more cam lift and more duration.

“We’re trying to fit everyone’s needs,” Slemmon says. “Our Coyote engines could have 500-900 horsepower naturally aspirated. If we put a power adder on there, it could be a 2,000 horsepower engine.”

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].