Making Dollars and Sense Cleaning Blocks, Heads

Unless you’re starting with all new parts, cleaning is as important to your engine build as disassembly, inspection, machining and reassembly. Without taking the cylinder heads and engine blocks down to bare metal, you can’t properly inspect the castings for cracks, wear and other defects. For something so important, proper cleaning technique is often misunderstood, overlooked

Cleaning Cylinder Heads and Blocks

The cleaning process should remove all of the dirt, grease, oil, rust, scale and carbon deposits that have accumulated over the years. With painted castings, the old paint also has to be stripped away so the surface can be repainted. Even if you’re working with brand new castings, a final cleaning is still necessary after

A Chip Off The Old Block: Aftermarket Blocks Are More Versatile Than Ever

It’s the same economic principle many body shops use on their rodding customers. You can expend good time, money and effort trying to resurrect an old hulk towards the customer’s ultimate goals or you can cut to the chase by starting with an accurate reproduction. In engine building, the same holds true but with a

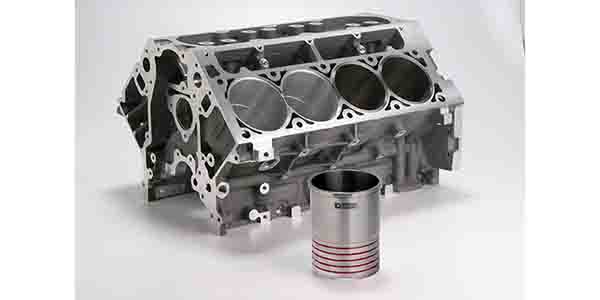

Engine Blocks & Cylinder Sleeves

In our February 2009 issue, Technical Editor Larry Carley provided a comprehensive overview of the changes in engine blocks over the years. Thanks in part to natural attrition (after all, many of the most popular engines were actually designed and built more than 50 years ago) and the high price for scrap metal in the

Resurfacing Cylinder Heads & Blocks? Mistakes to Avoid

Cylinder heads and blocks may need to be resurfaced to restore flatness or to improve the surface finish, or milled to change the deck height for a variety of reasons. The deck surface on the head or block may need to be resurfaced if the surface isn’t smooth or flat. A head may need to

Cleaning Aluminum Engine Components

Engine rebuilding may be your career, but component cleaning may be one of your biggest jobs. Ever since the earliest days when engine builders had only a hot tank and a solvent sink to clean their parts they have been looking for better methods to get parts clean. Back then, most parts were cast iron

Welding: Why weld aluminum?

As we are all aware, many of the components of the engines our industry remanufactures utilize this "mystery" metal. It first started with manifolds, then cylinder heads, timing covers, oil pans, lower main bearing girdles and finally blocks and all accessory mounting brackets. Don

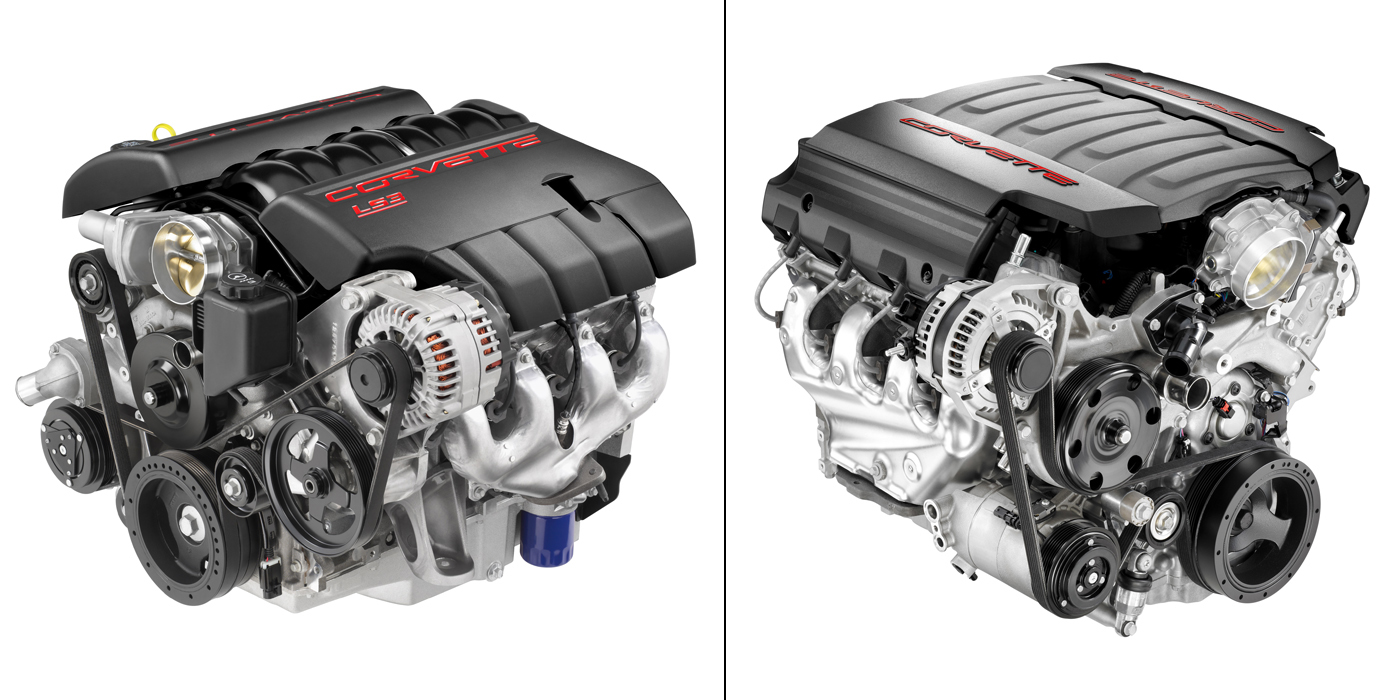

Choosing the Correct Block for Your LS Engine Build

Whether you’re scouring junkyards, ordering cores, investigating factory options, looking at aftermarket cast iron or aluminum blocks, or spending big bucks on billet LS blocks, you’ve probably noticed it’s been harder to find exactly what you want for the foundation of your LS build than it historically has.

Sleeves and Liners – Metallurgic Magic

Dry sleeves and wet liners have long been used to repair and restore cracked or worn engine cylinders, but they are also used to reinforce aluminum blocks that are being built for serious performance applications.

Shop Solutions June 2016

We live in a time where aluminum blocks with cast-in sleeves are common and we still need to remember to account for how different metals behave. We build several dozen Gen III and Gen IV GM LS type motors per year. We finish our cylinders .001” tighter on the aluminum block engines to compensate for the additional growth when the block gets up to operating temperature.

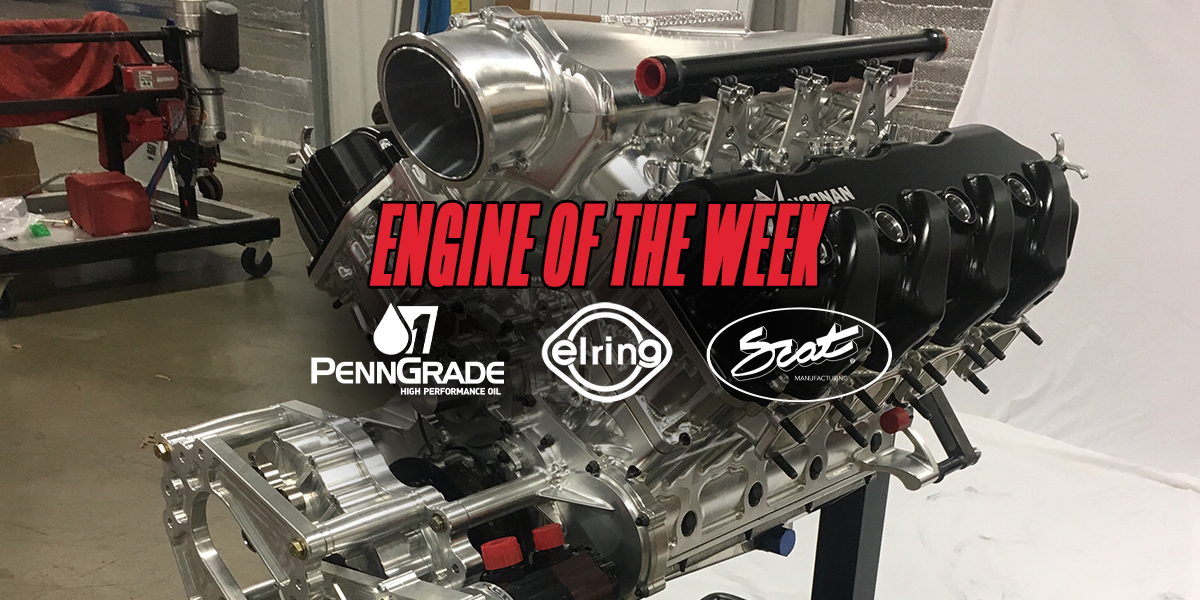

3,500+ HP 427 cid Billet LS Engine

At ACE Racing Engines, Stefan Rossi’s and Laura Pugh’s hard work has been paying off in the form of increased awareness and business, a new shop space out in California, and best of all, success on the track from numerous customers. Check out this excellent example of a maximum effort, billet LS engine for a drag-and-drive application.

Shop Solutions – February 2024

Submit your Shop Solution at [email protected].

Shop Solutions – January 2024

Before installing cam bearings, make sure to chamfer any oil holes and clean up back grooves of any sharp edges.

760 cid Billet Big Block Chevy Nitrous Engine

Despite what you may think about nitrous engines, and those that are stock big block Chevy bore spacing, these 4.840″ bore space big block Chevy engines have some significant R&D in them. Just check out this 760 cubic inch billet version done at TRE Racing Engines.

Billet Triple-Turbo 6.4L Cummins Super Stock Engine

During a recent visit to Scheid Diesel, we got to see what goes on in the Terre Haute, IN-based engine and machine shop. We also got a deep dive on the details of a $150,000, billet, triple-turbo, 6.4L Cummins Super Stock engine build. It’s the pinnacle of Scheid Diesel builds, so don’t miss what’s in and on this engine.

Darton Ford Modular Seat Tight Sleeve

This sleeve makes the block much stronger than the stock aluminum using ductile iron sleeves.

Rebuilding Chevrolet’s Gen VI Big Block Engine

Following Chevy’s introduction of its popular small block V8 in 1955, the OEM needed something larger to power its medium-duty trucks and the heavier cars that were

on the drawing board at the time. Enter the big block!

Import Engines: A Look at the 2JZ

Many of the biggest names in motorsports have built and used the 2JZ in their own racing machines, proving that the engine platform can be competitive in various formats.

Choosing Between the LS and the LT: The King and the Heir to the Throne

There are times when the “eeny, meeny, miny, mo” approach works well for decision making, and other times when you really need to stop, look at all of the variables and then make your choice. For today we’re going to focus on deciding between two GM V8 engines, the LS and the LT.

4.9″ Billet Hemi ‘Big Dawg’ Engine

When we spoke with Darrell Makins, shop manager of Noonan Race Engineering in Spartanburg, SC, the shop had 60 billet blocks in queue for production. Noonan Race Engineering starts each build from an 815-pound raw chunk of aluminum. With 60 engines on deck, that makes for nearly 49,000 lbs. of raw aluminum. After getting machined,