Sodium Bicarbonate – A User-Friendly Blasting Abrasive

Sodium bicarbonate blasting or soda blasting, is a user-friendly process for the removal of grease, oil, burnt carbon and many other contaminates experienced in engine building. There are many different processes for cleaning parts and components before engines can be rebuilt, however they are not all equal.

Engine Part Cleaning Tips and Techniques

It’s not fun, but vital to successful rebuilds According to a recent Engine Builder Machine Shop Market Profile, in which we survey hundreds of machine shops across the country, about 15 percent of the total production time for rebuilding an engine is spent in the cleaning process. While our wives may not agree that we

Safe Cleaning – Are the Concepts Compatible?

The subject of cleaning is never far from the mind of the modern engine builder or machine shop supervisor. Obviously, parts must be as clean as possible so they can be inspected, repaired if possible and reassembled. The subject of SAFE cleaning is a little less definitive, however.

Blast Off – What’s New in Blast Media and Machines

In this industry, it’s often cheaper to remanufacture or rebuild an engine than it is to make a new one. However, doing so requires cleaning worn and dirty parts. In addition, customers these days are increasingly asking for cleaner parts and engines. How are you supposed to get tough grease, oil, rust, paint, carbon build-up,

Revved Up – Why the Import Engine Market is on the Rise

For numerous reasons in recent years people have been fixing engine issues rather than replacing engines altogether, making for a strong outlook in the import engine market. There are several ways you can break into this market or improve your stance here if you’re already an import engine builder.

Spick-and-Span

As engine technology continues to evolve, so have the cleaning processes for removing dirt, grease, oil, hard carbon deposits, rust, scale, corrosion and discoloration from engine castings and components. Several factors make cleaning more challenging today.

Being Green Takes Some ‘Engine’uity

You might not have even realized, but by being an engine builder/rebuilder alone, you’re already contributing to making the environment a greener place. That’s right, it takes less energy and less material to rebuild an engine than it does to build a brand new one. So since you’re already being ‘green,’ why not go a few steps further?

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

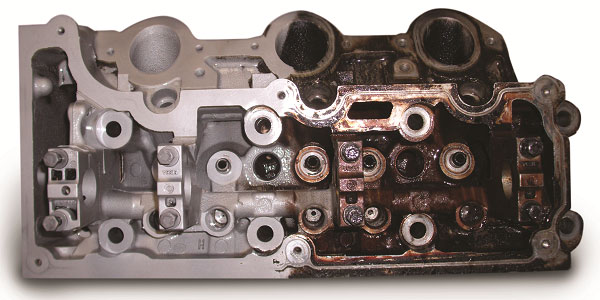

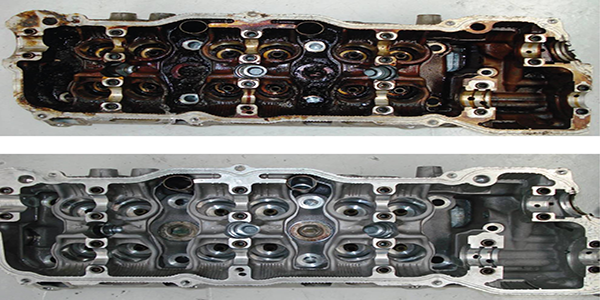

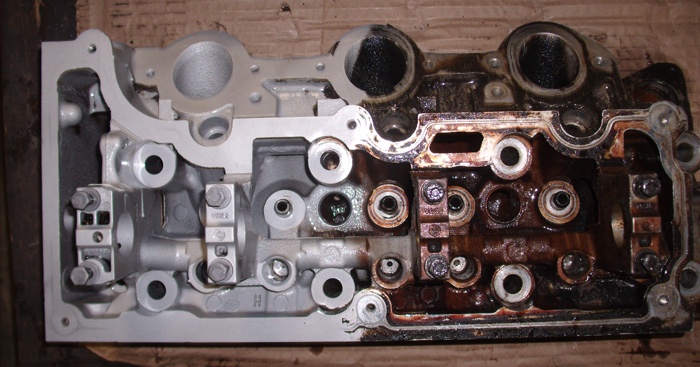

Cleaning Engine Blocks & Engine Cylinder Heads

Cleaning engine blocks and cylinder heads is just as important as the machining operations you will perform on the castings. You can’t do a thorough job of inspecting these parts if they are dirty, greasy or covered with paint or corrosion. Checking for cracks in cast iron heads and blocks requires a clean surface for

Today

Although extremely important, the job of cleaning engine parts leaves nothing to the imagination. You’re idly standing with a spray gun in your hand or beside a washer tank or cabinet. It’s a basic, time-consuming procedure, but that grime, oil and baked-on sludge won’t come off by itself. This necessary evil is the difference

BIG R Show to Feature Seminars from RIT’s Reman Center

Automotive parts remanufacturing is becoming more competitive every year. Progressive remanufacturers are always looking for new ways to save money through process improvements. Surface cleaning is one step inthe remanufacturing process where companies can typically find improvement opportunities due to the ever-increasing number of new chemistries and technologies available. Once identified, how does a company

Cleaning Engine Parts: Can You? Should You?

Here’s the kicker – those shops who feel that proper cleaning is too difficult, too time consuming or too expensive are actually leaving money on table when it comes to their engine parts. “At one point in my career, cleaning seemed like it was really difficult,” says Dave Arce of Arce Enterprises, El Cajon, CA.

Making Dollars and Sense Cleaning Blocks, Heads

Unless you’re starting with all new parts, cleaning is as important to your engine build as disassembly, inspection, machining and reassembly. Without taking the cylinder heads and engine blocks down to bare metal, you can’t properly inspect the castings for cracks, wear and other defects. For something so important, proper cleaning technique is often misunderstood, overlooked

Engine Builder Shop Solutions: September 2011

Editors note: The first two Shop Solutions are responses to Larry Carley’s article “Cleaning Heads and Blocks” in the July 2011 issue of Engine Builder. Cleaning Vintage Mercedes Parts I enjoyed the July 2011 article “Cleaning Heads and Blocks” and wish to include a tech tip about the use of caustic cleaning on vintage Mercedes

Cleaning Cylinder Heads and Blocks

The cleaning process should remove all of the dirt, grease, oil, rust, scale and carbon deposits that have accumulated over the years. With painted castings, the old paint also has to be stripped away so the surface can be repainted. Even if you’re working with brand new castings, a final cleaning is still necessary after

Media and Solutions For Cleaning Engine Parts

One essential aspect of engine building and rebuilding that cannot be avoided is the need for cleaning. Used engine parts have to be cleaned before they can be inspected. Parts that will be reused also have to be cleaned to remove dirt, grease, oil, carbon, rust, scale and other gunk that could contaminate a newly

Understanding Today

Metallurgy is one of the oldest sciences in the world – it’s a history that can be traced back to the beginnings of civilization. It’s hard to believe that in the thousands of years since the discovery of gold and silver there have only been 84 new metals discovered. In fact, when the automobile was

Cleaning Up In The Shop

In fact, it can be very difficult to make an accurate diagnosis of what’s wrong with an engine until it’s clean. You may be able to recognize some failed parts, you can often see large cracks or obvious damage, but you’re really only assuming you know what caused a failure if you can’t see for

High Tech Cleaning Options

Yet while machining tolerances and performance expectations have changed dramatically over the past few decades, when it comes to getting parts clean, many of those high-tech shops struggle with the same technology they used 30 years ago. The simple fact is, times have changed for parts cleaning, and so have the methods. Engine builders have

Cleaning: Different Methods for Different Needs

Back in the late 1800s, the director of the U.S. Patent Office was said to remark “Everything that can be invented has been invented.” Charles Duell, U.S. Patent Commissioner in 1899 reportedly told the President of the United States that there was no more innovation and, therefore, no more need for the patent office. Except