Understanding Today’s Bearing Clearance Recipe

What’s needed to keep the rotating assembly rotating? It’s a recipe that includes three key ingredients: the bearing, the crankshaft and the oil. But understanding the part each plays as part of this recipe is what’s needed to keep your engines’ bearings from failing.

Replacing Crankshafts, Connecting Rods and Bearings

The crankshaft, connecting rods and bearings are extremely important in every engine build, whether mild or wild, because they convert the reciprocating motion of the pistons into rotational torque. The longer the stroke, the greater the leverage effect and the greater the torque output of the engine. There are three things that need to be

Crankshafts and Bearings for Street Performance and Racing

The crankshaft and bearings are the foundation of any engine. The type of bearing and crankshaft materials that are used, their strength properties, fatigue resistance and ability to handle high torque loads ultimately determine how durable the engine is and whether it goes the distance or self-destructs. Most engine builders have strong opinions and

Getting Your Bearings

Engine bearings have a tough job to do for such a small component. They must support big loads on a thin film of oil (between .0001-.0004? thick) between themselves and the crankshaft journals to prevent metal-to-metal contact. One of the biggest causes of bearing failures is dirt and debris that enters into the oil pan

Engine Bearings and Crankshafts: Best Friends Forever (BFFs)

Bearings appear to be such simple engine components. On the surface, they’re just half-circles of metal whose only purpose is to reduce friction between and support moving parts. The engine bearing has to establish and maintain a film of oil between moving and stationary parts to prevent wear to expensive engine components. They look like

King Engine Bearings Technical Seminar Video Now Available

Ron Sledge, King’s performance and technical manager, presented "Race Engine Bearing Lubrication, Clearances & Tolerances" at both the Performance Racing Industry Trade Show (PRI) and International Motorsports Industry Show (IMIS) events. The hour long presentation is now available to view, free-of-charge at www.kingbearings.com/tech_materials.php. Sledge shared his knowledge of engine bearings and race engine

Communication Breakdown: Diagnosing Engine Bearing Failure

Engine builders turn into medical examiners when this happens; getting the story behind the story is what you must do to understand what went wrong and what to do to avoid it in the future. According to engine bearing experts, a failed bearing is not usually the fault of the bearing but rather the fault

Crankshafts and Bearings for Street Performance and Racing

Most engine builders have strong opinions and brand preferences when it comes to choosing a crankshaft and bearing combination for a performance engine application. Their preferences (and prejudices) are usually based on years of experience, both good and bad. Many subscribe to the philosophy that “if it isn’t broke, don’t fix it!” Consequently, if they

CSI: Engine Bearings: When Good Bearings Go Bad

Engine bearings have the dual function of reducing friction between a rotating part of the engine (the crankshaft) and the stationary part (the main caps and engine block) and supporting the crank. Because of the stresses caused by the explosions inside the internal combustion engine, the bearing material must be extremely strong, so a durable

Engine Bearings: Stock & Performance

The importance of the engine’s bearings can’t be over-emphasized. The bearings support the crankshaft and connecting rods, and in pushrod engines also the camshaft. The bearings provide a surface for the friction-reducing oil film that allows the parts to spin without rubbing metal against metal. It’s a tough job because of the high loads created

Crankshafts and Bearings – Keeping the Relationship Strong

Today’s engines typically have very tight tolerances everywhere and the crankshaft bearings are no exception. The truer the crank is in its alignment with the mainline and cylinder bore, the tighter the tolerances can be. Bearings and mainline bores must be very precise because during operation the crankshaft is not actually straight: it is elastic.

Ensuring Bearing Life: Crankshaft Bearings Are Always Replaced When Rebuilding An Engine

Crankshaft bearings are always replaced when rebuilding an engine because they’re a wear component. Heat, pressure, chemical attack, abrasion and loss of lubrication can all contribute to deterioration of the bearings. Consequently, when an engine is rebuilt new bearings are always installed. “Reading” the old bearings can reveal a great deal about conditions that may

Motor Oil Issues

One of the challenges of building engines for a living is making sure that every engine you build has good oil pressure and suffers no lubrication-related issues once it goes out the door. Good oil pressure requires main and rod bearing clearances that are within your target specs for the application, a good oil pump and the “right” motor oil.

November 2014 Shop Solutions

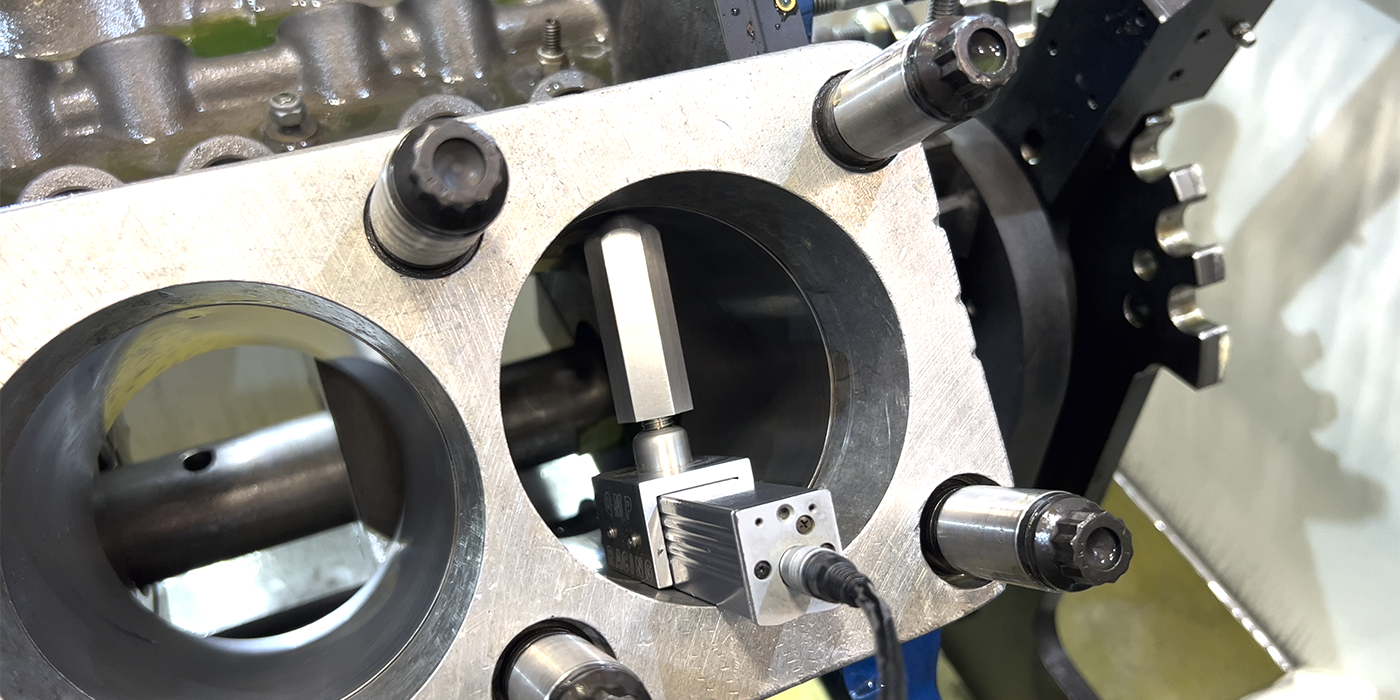

One of the main problems with blocks that need to be align-bored is the lack of squish between the main cap and the block. What I am referring to is the interference fit between the cap and main register that holds the cap in alignment, and is the reason a light tap is needed to seat the cap. If the caps do not fit tight, the crank will not be held as solidly as it was intended, and also results in inconsistent bearing clearances.

2,600 HP ProCharged 540 cid Big Block Chevy Engine

BB&T Racing in South Haven, MS has been building high-performance domestic engines for 30 years. One of their latest builds is for a drag racing customer looking to go faster utilizing an F3 ProCharger. Check out this 2,600 hp ProCharged 540 big block Chevy engine!

Race Oils

Choosing the correct performance racing oil is essential to ensure optimal performance and longevity of your engine.

Tight Tolerances and Building Power

As you ascend Mt. Everest, you reach an area called the death zone. Once you climb high enough, the margin of error becomes perilously thin. That death zone also applies to engines. As the horsepower per cubic inch and rpm increase, the margin of error decreases.

Building Big Block Marine Engines

Find out what it takes to build a formidable marine engine.

Developing a Honda 2.3L Engine for Road Racing

One of the most important aspects of engine building has nothing to do with the engine at all. You have to understand the customer and what they are trying to achieve.

Women in Motorsports: Katie Coleman

Katie is an engine builder and cylinder head specialist for LinCo Diesel Performance (LDP) who has more than 15 years of engine shop experience. Her level of experience, knowledge and talent is always in high demand.