Blast Cabinets: Equipment, Media Options Make Quick Work of Different Cleaning Needs

No two custom engine builders use the same team to create their engine products nor do they create the same engine or use the same parts. Just like each application has different design outlines so do abrasive blasting machines that are used to clean, strengthen, shot peen and rebuild custom engines for use in vehicles from fleets to racing.

Blast Off – What’s New in Blast Media and Machines

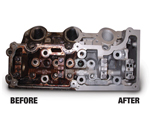

In this industry, it’s often cheaper to remanufacture or rebuild an engine than it is to make a new one. However, doing so requires cleaning worn and dirty parts. In addition, customers these days are increasingly asking for cleaner parts and engines. How are you supposed to get tough grease, oil, rust, paint, carbon build-up,

Maximize Your Grinding Efficiency

Today’s shop owner is always looking for the edge, the next big business opportunity – and you may not even realize that your flywheel grinder can be one of the most profitable machines in your business.

Goodson Translates 2016 Catalog to Spanish

Goodson Tools & Supplies for Engine Builders has completed the translation of its 2016 catalog into Spanish. the electronic catalog includes all current products offered by the company and is intended to replace all previous catalogs and supplements. This edition includes information on Radiac Abrasives and Kwik-Way Valve Grinding Equipment and Supplies, both now available

Honing Aluminum Blocks

Manufacturers who produce “linerless” hypereutectic aluminum blocks today include Audi, BMW, Honda, Mercedes, Porsche, Volkswagen, Volvo, and Yamaha. Most late-model engines have aluminum blocks to save weight, including most of the familiar domestic V8s such as Chevy LS, Ford 4.6L modular and 5.0L Coyote, and Chrysler 5.7L and 6.1L Hemi. Yet these have iron sleeves.

The Daily Grind

Today, seats are made of a wide variety of materials, different combinations of various alloys, powdered metals and other super hard materials. This seat material is designed to prolong the ability of the valve seat to seal against the pounding of the valve head during engine operation. The variety of materials also means new and different abrasives are required for proper machining.

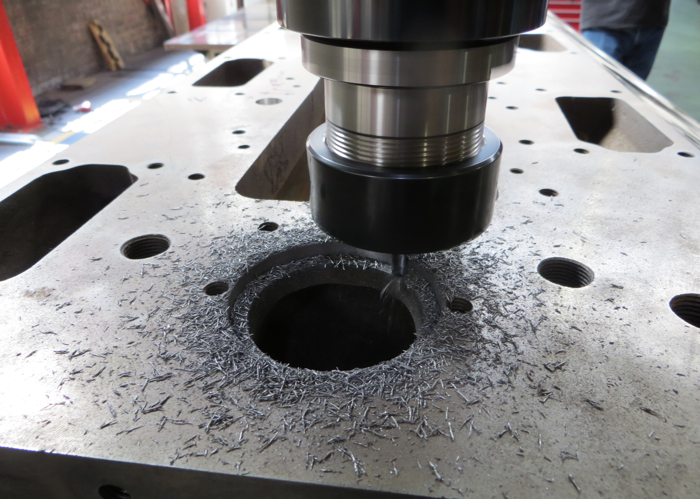

Modern Machining

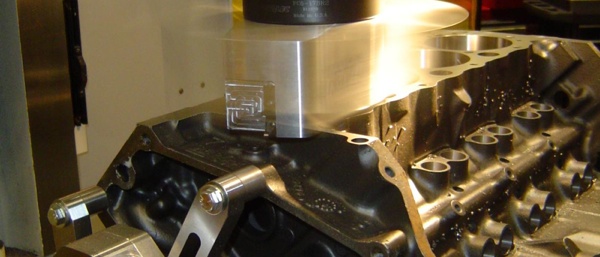

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

PERA To Host Technology of Cylinder Honing Webinar

Join PERA for a webinar about cylinder honing technology on Oct 14, 2015 at 10:00 AM CDT. Bob Dolder, Automotive Sales and Application Manager will cover all the facts you need to know and more.

Is Non-Destructive Cleaning Critical? ARMEX is the Only Choice

When part specifications and surface tolerances cannot change, the only blasting abrasive to use is ARMEX. The gentle physical propriety of baking soda, yet aggressive cleaning ability is what makes ARMEX the only choice.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

Engine Builder 50th Anniversary

The next time you’re on a TV game show or playing trivia with friends, and the question is, “What is the most significant month in the history of the transportation industry?” let me suggest that you answer, “October 1964.” May I present the evidence for my argument? October 1, 1964: The world’s first high-speed rail

Sunnen Introduces Digital SH-4000 Honing Machine

The horizontal SH-4000 introduces servo-precise, digitally repeatable performance, intuitive touchscreen HMI, infinite part program storage, larger workpiece capacity and operator-friendly safety features.

Head Surfacing and Straightening

Clean, smooth and flat have always been requirements for proper head sealing whether you are building a stock engine or a monster motor for a ProStock drag car. Head gaskets can only accommodate so much distortion and roughness across the face of the cylinder head and deck. Resurfacing the desk surface on a cylinder head and/or engine block should restore flatness and achieve the required smoothness.

Oil Eater Original

Uniquely formulated to eliminate the need for multiple solutions, the new Oil Eater Original is a powerful water-based cleaner-degreaser that quickly dissolves grease, oil and grime on engines, power equipment, tools, concrete, asphalt, floor mats and even uphostery. The eco-friendly, all-purpose cleaner is biodegradable, non-flammable and contains no acids, abrasives or petroleum solvents. It penetrates rapidly, rinses off easily, leaves no residue and will not harm the skin. It is also

Oil Eater Expands Floor Cleaner Line

Oil Eater has expanded its line of floor and all-purpose cleaners with the introduction of an economy 38 lb. lined case of powder, an addition to its pre-measured 1.5 oz. packets. Designed to keep waste to a minimum, the ultra-concentrated, eco-friendly powder can be used in a mop bucket, auto scrubber or even in spray

Choosing the Right Rings

Choosing piston rings for a performance engine build is not as simple as it sounds. Your ring choices may be limited depending on the dimensions of the ring grooves that are available. The location of the wrist pin may also limit what you can do with rod length and stroke if you want to build

Racing Oils

The latest API-certified SN and ILSAC GF-5 motor oils are fine for everyday driving in late model vehicles, but most off-the-shelf motor oils (even many synthetics) come up short in the anti-wear department in a racing application – especially if the engine is running a flat-tappet cam or a radical roller cam with a lot

Racing Oils

Performance engines built for racing deserve the best possible lubrication. Ordinary street oils don’t cut it on a race track. By Larry Carley The latest API-certified SN and ILSAC GF-5 motor oils are fine for everyday driving in late model vehicles, but most off-the-shelf motor oils (even many synthetics) come up short in the anti-wear

Green Strategies: Cleaning Techniques & Equipment

It may seem that there’s nothing natural about cleaning an engine. Even after the couple of hours of cleaning time, the engine might be cleaner than the tech working on it – but the engine still needs cleaned (and so does the cleaning crew from time to time). We are long from the days of

World’s Smallest V8 Engine

Gary Conley’s 30-year quest to manufacture a true production V8 engine in quarter-scale almost went up in smoke twice, once in 2001 when a foundry fire claimed all his critical molds, and later when oil smoke proved a stubborn problem during run-offs of the engine. Conley overcame the first setback with years of sheer determination.