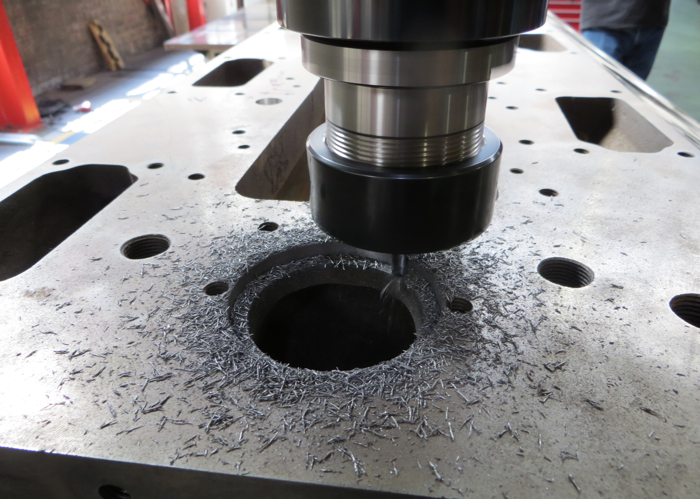

Why Cutting Fluids Are Imperative to Machining

In order to produce the best performing engines with tight tolerances and finishes, CNC machines require cutting fluids to perform at the highest levels. You might think a fluid is a fluid is a fluid, but you’d be wrong.

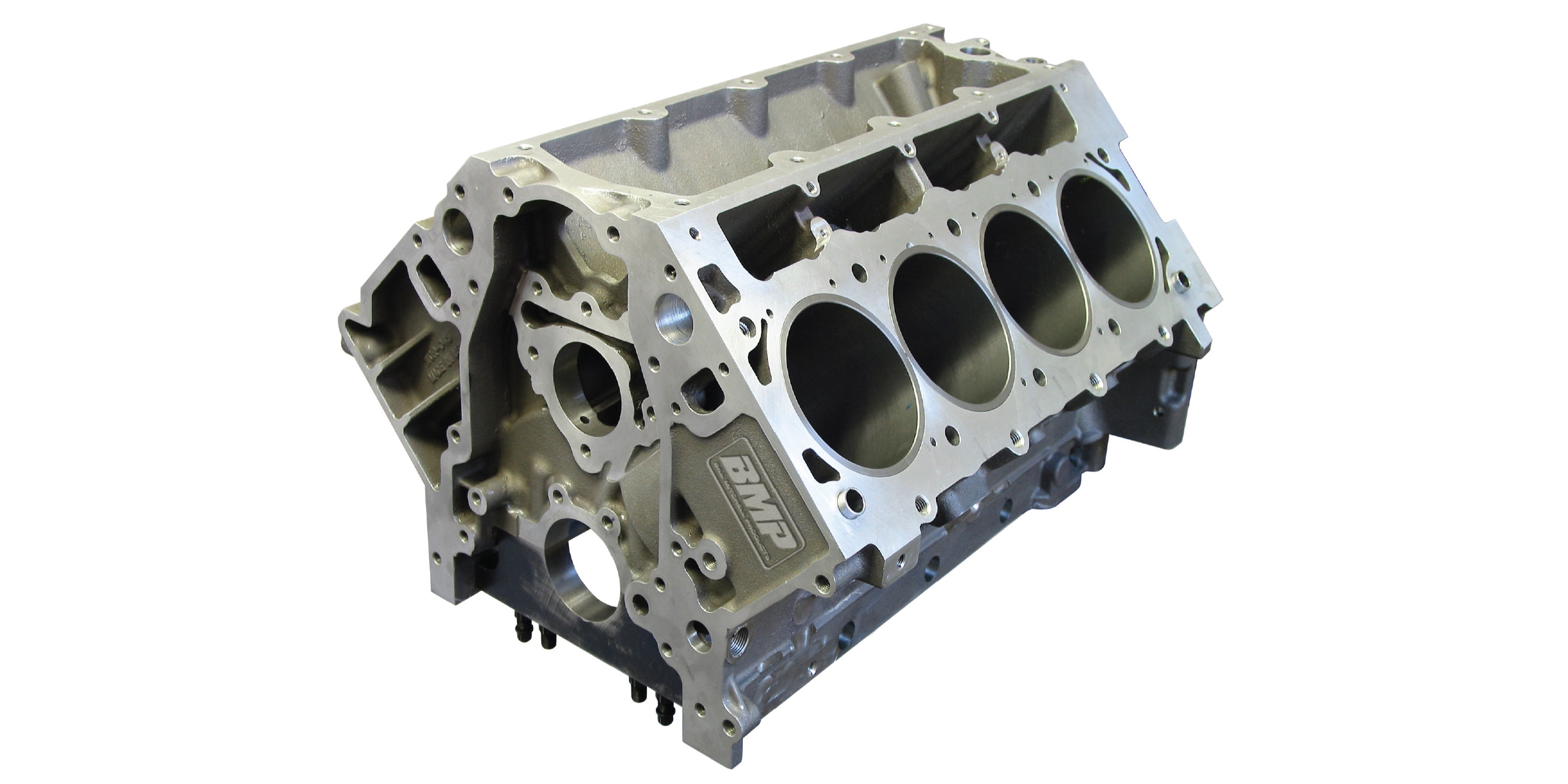

Machining Aluminum Engine Blocks

Aluminum engine blocks have been around for many years for both stock and performance applications. Aluminum has a number of advantages over cast iron, the most obvious one being weight.

Hidden Horsepower – How Simple Machining Steps Can Provide a Win-Win Power Upgrade

In the automotive industry, power and reliability have always been the quest of all engine builders and racers. There are many time-honored methods of increasing horsepower and the same with making engines more reliable. But modifications can sometimes have residual effects and overtax another area of the engine, even compromising reliability. For example, raising compression

Engine Balancing – Explain the Benefits to Sell the Balance

Over the years I’ve seen many articles on engine balancing and it seems that most of them get pretty technical and complicated. It is always nice to understand the depth of what you are trying to accomplish, but we cannot lose focus of the ultimate goal – which is to give the customer the best-balanced

The Value and Benefit of Sonic Testing

Sonic testing is probably one of the most valuable tools of engine building – and often the most overlooked. It allows the engine builder to gain a basic perspective of the integrity of the parts that are going to be used for the engine build.

Maximize Your Grinding Efficiency

Today’s shop owner is always looking for the edge, the next big business opportunity – and you may not even realize that your flywheel grinder can be one of the most profitable machines in your business.

Comau SmartDriveComau 800L Horizontal Machining Center

SmartDriveComau 800L is a horizontal machining center that covers primary manufacturing needs, both as a single machining center or integrated within a highly flexible production line. This powerful machine, the latest from Comau Powertrain Machining & Assembly, is the new generation model.

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

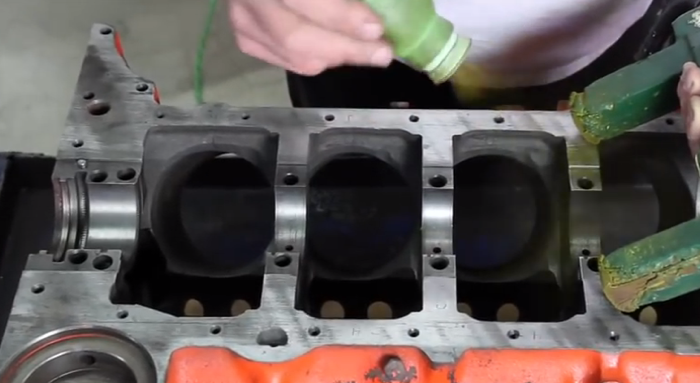

How To Machine a Chevy 350 V8 Small Block

A Chevy 350 small block goes to the machine shop to show you the process of machining a block.

The STURM Group and MAG IAS Group Present Engine Technology of the Future

The STURM Group and the MAG IAS Group are presenting a world premier: the STURM coating center ACCS TWS aligned with SPECHT machining centers. The two collaborating companies offer a turnkey plant for the series production of cylinder blocks with thermal bore coating.

Guide Discusses Securing Cylindrical Assemblies

20-Page Brochure Highlights Increase in Joint Strength and Reduction in Assembly Costs Henkel Corporation has created the Loctite® Retaining Compound Design Guide, a new 20-page brochure available in print and online that provides detailed information on anaerobic retaining adhesive technology and its engineering and cost benefits, real world applications and product and equipment options. Loctite

2010 Performance Machining & Engine Parts Guide

(Download and view the .pdf here) Sponsored By: