With all of the bolt-on diesel components that are available on the market these days, why would you get into offering performance engine rebuilds for the diesel market? I’m sure you are asking yourself this question every time you get a call from someone with a diesel engine asking how they can get more power. But believe me when I tell you it is a growing market. And better yet, it’s one that can make you money!

Over the last three years the used diesel truck market has seen a yearly increase in sales of about 10-12 percent and is slightly above new diesel trucks sales. This tells you the older trucks are still in use and require more maintenance from the local diesel shops or garages.

If you are familiar with diesel engines, and how they work, you know diesel engines last longer than their gasoline engine counterparts IF they are maintained properly throughout their life. Like any good technician will tell you, whether it’s gas or diesel, an abused engine will fail when you need it most.

Today’s diesel enthusiast often knows the basics of how to work on his diesel engine, but when something goes wrong internally, that’s when he will seek you out for repairs. This is a huge opportunity for a local shop to step up and solve your customer’s problem.

The common theme that we see over and over with diesel guys is that they add bolt-on performance items without thinking of reinforcing the internal parts of the engine or drivetrain. Bigger doesn’t always mean better when it comes to diesels, you upgrade one component you had better upgrade other important parts of the engine as well.

I get calls all of the time from people who have a blown engine, blown the turbo or blown tranny. I ask them immediately, “Did you turn your tuner up all the way and floor it?” And most answer, “Yeah, sure did!”

Yes, many bolt-on components can produce extra horsepower and torque, but the problem is the original stock engine is not rated for that much power, so when it is pushed to the limit, parts start breaking.

I will cover some of the engine parts that break easily when this happens, and I’ll cover a few each month in my Diesel Motorsports column in the pages of Engine Builder until we have explored all aspects of a performance diesel engine.

One of the first questions I ask is, do you have performance head bolts installed? If your customers are increasing the power through various bolt-on components, the heads and rods are the first to cause significant problems inside the engine.

In fact, many turbo suppliers are now recommending that customers install performance head bolts before using their products!

Building For Performance

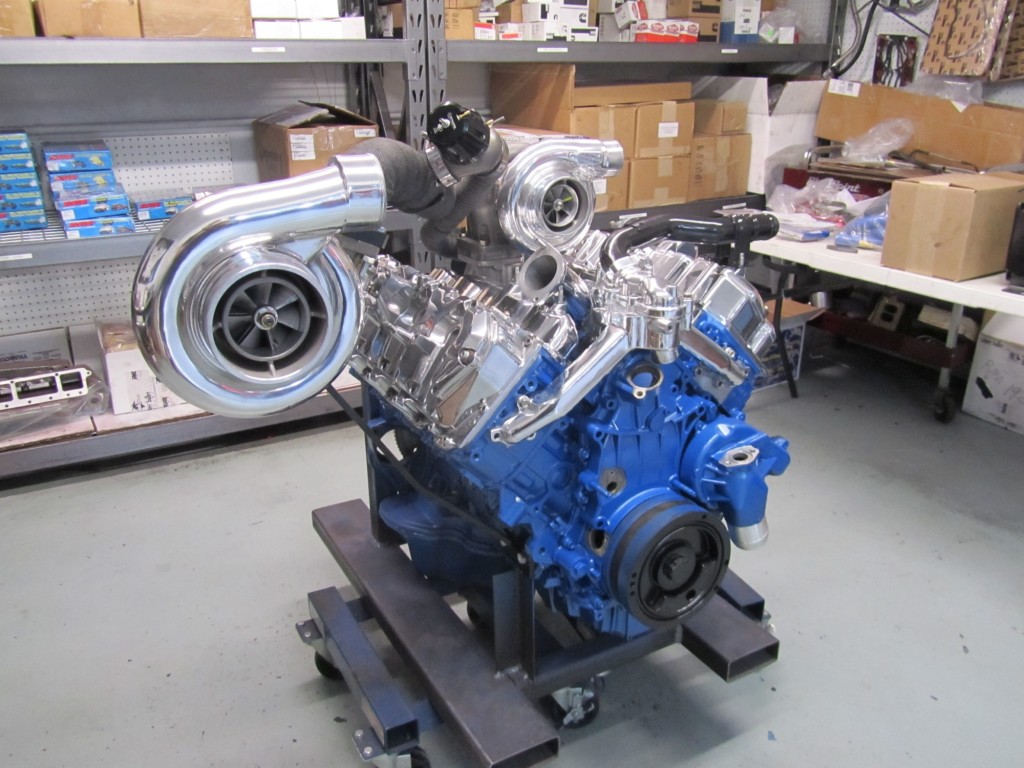

Building a performance diesel engine takes a different approach than a performance gas engine build. While most diesel engines are turbo-charged, they make most of their torque and power at relatively low rpm. The bottom end in a diesel engines is already fairly stout, with forged steel crankshafts and heavy-duty connecting rods, so the amount of modifications that may be needed are usually minimal for a mild performance build.

And because most street performance and pulling applications don’t require a lot of rpms, engine balance is not as critical as in a high-revving gas engine. However, pistons may have to be cut, modified or replaced, depending on how much turbo boost the engine runs, and what kind of modifications are being made to the camshaft and valvetrain.

[inpost_gallery post_id=3446 group=”1″]

Because diesels require a lot of compression, camshaft duration tends to be short with minimal overlap. Valve lift may also be limited by the tight piston-to-valve clearances in some diesel engines. So unlike gas engines, you can’t go with extreme lift and duration setups to make more power. A bigger camshaft can provide more power, but only if the lift and duration are right for the turbochager, cylinder heads, pistons, valvetrain and application.

The most significant power gains in a diesel engine come from increasing the amount of boost delivered by the turbo (or turbos if their are multiples). But there’s more to it than just bolting on a bigger turbo. The camshaft must have the right exhaust characteristics so it will spool up the turbo faster and keep it spinning at peak efficiency in the engine’s power band. For some types of pulling, the power band can be quite narrow, maybe 3,000 to 5,000 rpm for a diesel pulling truck. A street truck, by comparison, may make most of its power at even lower rpms.

If engine speed drops too low during a truck or tractor pulling event, the turbo can stall or “chirp,” causing the boost pressure to suddenly drop. This kills power and may even cause the engine to stall.

Diesel experts say that one of the tricks to getting more power is to pay more attention to the pressure developed in the cylinders. With gasoline engines, you want to increase valve duration to get more power. But this approach doesn’t necessarily work with all diesel engines. By doing just the opposite and decreasing duration you will gain more power, say some experts.

One tip for Cummins engines is that the press fit cam gears used up to 2003 have a tendency to push off the end of the camshaft if the engine is modified to produce over 600 horsepower. For modified Cummins engines, converting to a bolt-on drive gear set is recommended.

Since most diesels run at relatively low rpms compared to gas engines, modifications to the valvetrain are often not necessary for mild builds (until they want big horespower, that is). This means you don’t need monster springs and pushrods to prevent the valves from floating at high speed. On the other hand, there may be some concerns about the effects of turbo boost on the intake valves.

Many diesel engines run very high boost pressures, from 80 to as much as 200 psi on some really extreme engines. So there’s a concern that really high boost levels may overcome the force exerted by the springs on the intake valves forcing the valves open.

While some diesel experts say that for every 10 psi increase in boost, you should use springs that are at least 10 psi stiffer than the stock springs, others say this really isn’t necessary because when the piston is coming up on its compression stroke, the pressure developed inside the cylinder will hold the intake valves shut.

On Cummins engines, for instance, there is a concern that overly stiff valve springs may increase wear in the cam bores. In Cummins engines, there are no cam bearing inserts – the camshaft journals run directly on the machined bores in the block. Because of this, extremely heavy valve spring pressure pushing the rocker arms, pushrods and lifters down against the camshaft may cause the bottom of the cam bores to wear out.

As the cam settles lower and lower into the block, it upsets valve lift and timing, causing a significant loss of power. One way to prevent this in a performance Cummins engine with stiffer than stock valve springs is to machine out the cam bores in the block and install aftermarket bearing inserts.

Any engine builder who is currently doing gasoline engine performance work could probably do diesel performance work too, say diesel experts. You do have to learn about diesel fuel systems and how to correctly set up the injection pump, injectors and turbo. But the machine work you do on the block, heads and other internal parts are pretty much the same as any other performance engine.

Many diesel performance engines are running 130 to 180 psi of boost pressure, so when you modify a stock engine to produce significantly more power, you also have to increase the flow capacity of the fuel system. You may have to modify the injection pump so that you can double the fuel delivery. The injectors can be modified by increasing the number and size of the nozzle orifices. Stronger fuel lines are also a must to handle higher fuel pressures.

There are also ample opportunities to do diesel performance modifications for the street. It’s fairly easy to tweak the turbo and squeeze an extra 100 or more horsepower out of an engine without sacrificing fuel economy or everyday driveability. To maintain good driveability and throttle response, you want the turbo to spool up quickly and provide good low end torque.

Experts say that street-driven diesel trucks tyically develop peak power between 1,800 and 3,200 rpm. Depending on how the truck is geared, a drag truck may be set up to run at a somewhat higher rpm. But it doesn’t take much rpm to hit big torque numbers with a diesel.